HL nylon rod pin couplingHL nylon rod pin coupling has good toughness...

HL nylon rod pin couplingHL nylon rod pin coupling has good toughness... JSP type coupling with brake discJSP type couplings with brake discs generally should...

JSP type coupling with brake discJSP type couplings with brake discs generally should... YLD type flange couplingYL type flange coupling can be made of gray cast iron or carbon...

YLD type flange couplingYL type flange coupling can be made of gray cast iron or carbon... XL connection middle sleeve type star elastic couplingXL connection middle sleeve type star elastic coupling...

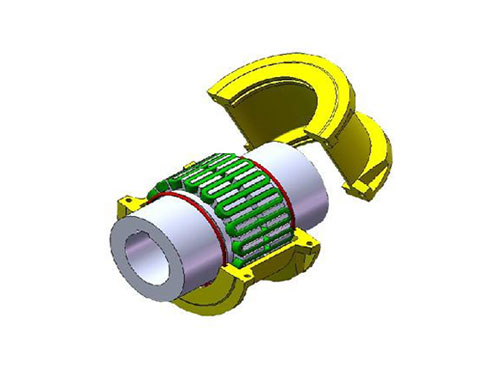

XL connection middle sleeve type star elastic couplingXL connection middle sleeve type star elastic coupling... JS type housing radial mounting type couplingSelection of JS type housing radial mounting type coupling...

JS type housing radial mounting type couplingSelection of JS type housing radial mounting type coupling...The method of installing bolts for diaphragm couplings and the advantages of diaphragm-type elastic couplings

Correct installation bolt method of diaphragm coupling:

Insert the bolt from the outside of the small hole in the flange, and then pass it into the diaphragm hole (pay attention to the direction of the diaphragm. The diaphragm is composed of many single sheets, rivets and rivet washers. The rivet washers should be in contact with the buffer sleeve, otherwise It will affect the service life of the rivet set), and then insert the buffer sleeve, elastic washer, and tighten the nut from the outside of the large hole of the flange, so that the bolt does not rotate, because the bolt and the flange are matched. The surface is an important part of the torque transmission, and the integrity of the surface directly affects the performance.

What are the advantages of the diaphragm-type elastic coupling?

XNUMX. Good flexibility: The encoder coupling needs to absorb to a large extent the deviation between the shaft and the shaft produced during the installation process.

XNUMX. Maintenance-free: After the coupling is installed, there is basically no need for maintenance, and the installation is particularly convenient.

XNUMX. Compact structure: Encoder couplings are usually small in size, and their clockwise and counterclockwise rotation characteristics are all the same.

XNUMX. Zero clearance: The entire coupling is not allowed to have clearance during transmission.

XNUMX. Low inertia: On the basis of transmission strength, the weight of the encoder coupling should be reduced as much as possible.

The diaphragm type elastic coupling basically has a variety of different ways of use in the actual use process, but sometimes such a product will appear black during use, then once it is really used After all, how should we deal with it?In such a manufacturer’s diaphragm-type elastic coupling, when these blackening conditions occur, a series of anti-rust effects should be exerted on the surface of the entire fastener, and during the entire processing process, Increasing the smoothness of their surface, in such a way to improve their aesthetics, and even reduce the stress in the quenching process.When the entire diaphragm-type elastic coupling enters some sending liquids, at first they may cause a series of corrosion to acidic objects, and may cause some dissolution of metals, or some other ions. Various substitution reactions occur.Then in this case, some of the original particles can replace each other and deposit on the metal surface, because some oxidants are added to the solution itself, so in addition, some different ions in the nitrite are reduced. This It can promote a series of oxidation reactions or other chemical reactions on their metal surfaces.

The diaphragm coupling compensates the relative displacement of the two shafts connected by the elastic deformation of the diaphragm. It is a high-performance flexible coupling with metal elastic elements. It does not require lubrication, has a compact structure, a long service life, and a rotation gap. , Not affected by temperature and oil pollution.The bolt of the diaphragm coupling is one of the important parts.The gap between the bolt fitting section of the diaphragm coupling and the flange hole fitting section is generally based on the bolt diameter of 0.20mm~0.30mm. This fitting section plays a key role in transmitting torque. If the gap exceeds the standard, it needs to be replaced.The diameter gap between the buffer sleeve and the inner hole of the diaphragm rivet and the bolt diameter is 0.5mm~0.7mm, which plays the role of pressing and positioning the diaphragm.

Diaphragm is divided into connecting rod type and whole piece type of different shapes.Stainless Steel Diaphragm Coupling Diaphragm compensates for the relative displacement of the two shafts connected by the elastic deformation of the diaphragm. It is a high-performance flexible coupling with metal elastic elements. It does not require lubrication, has a compact structure and a long service life. , No rotation gap, not affected by temperature and oil pollution.Key points for the use of diaphragm coupling diaphragm products: Appropriate stable protective measures should be taken at various sites that may be caused by the operating diaphragm coupling diaphragm and equipment accidents. During work and operation, the diaphragm coupling should be checked frequently Whether an abnormal phenomenon occurs, and if an abnormal phenomenon occurs, it needs to be repaired.

If the bolts are installed in the direction, it is easy to cause the bolts to deviate, and the diaphragm will be twisted and deformed.Therefore, pay attention to the direction of the bolt when installing the bolt. Do not install the bolt direction at will, otherwise it will cause the diaphragm to twist, and long-term operation will damage the surface of the diaphragm and the bolt mating section, and the small hole of the half shaft.The correct installation of the diaphragm coupling directly affects the performance life and stability of the diaphragm coupling, otherwise it will cause the waste of corresponding manpower and accessories.Therefore, the correct installation of the bolt direction is a critical step, and you must remember not to install it backwards or drop any small parts, including spring washers, so that the bolt assembly can exert its excellent performance and will not damage other parts of the coupling.