Star flexible coupling

Elastic sleeve pin coupling

Diaphragm coupling series

Elastic pin coupling

Drum type gear coupling series

Plum-shaped elastic coupling

Rigid coupling series

Tyre coupling series

Slider coupling series

Universal coupling series

Roller chain coupling

Water pump coupling

Various coupling accessories

Industrial expansion sleeve

Serpentine spring coupling accessories

Reducer bracket series

NL type drum gear couplingThe shaft hole types are cylindrical (Y), conical...

NL type drum gear couplingThe shaft hole types are cylindrical (Y), conical... XL type star elastic couplingXL type star elastic coupling and other coupling...

XL type star elastic couplingXL type star elastic coupling and other coupling... WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth...

WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth...XL connection middle sleeve type star elastic coupling

The XL intermediate sleeve type star elastic coupling has the characteristics of compensating for the relative deviation of the two shafts, damping, buffering, small radial size, high carrying capacity, and convenient maintenance. However, the two halves of the coupling need to be replaced when changing the elastic element. Move along the axis.It is suitable for connecting two coaxial lines, frequent starting, forward and reverse changes, medium and low speed, medium and small power transmission shaft systems, and working parts that require high workability. It is not suitable for heavy loads and restricted axial dimensions. Difficult parts of axis alignment.

The XL connecting middle sleeve type star elastic coupling uses a star elastic element to be placed between the two coupling halves to realize the elastic connection of the existing half coupling. The structure is compact, the size is small, and the inertia is small. It is made of engineering plastics. Elastic element, suitable for connecting two coaxial transmission shafts, with compensation for the relative deviation of the two shafts, buffering, shock absorption, energy, without lubrication, can work under the conditions of dust and water, simple structure, convenient maintenance , But you need to move the half coupling and the main shaft when changing the elastic element.It is suitable for general occasions, the transmission torque is 20-35000.NM, the working temperature is -35-+80 degrees Celsius, and it is interchangeable with the German ROTEX coupling.The polyurethane elastomer is limited by the convex claw block, which can avoid internal deformation caused by impact and external deformation caused by centrifugal force; the large concave surface of the convex claw makes the surface pressure on the involute tooth very small, even if the tooth is overloaded , The teeth will not wear or deform. The XL connecting middle sleeve type star elastic coupling is made of engineering plastics as elastic elements. It is suitable for connecting two coaxial transmission shafts. It has compensation for the relative offset of the two shafts, cushioning, shock absorption, and energy. It is widely used in applications. The transmission torque is 20-35000.NM, the shaft hole is 6-220mm, the allowable speed is 1800-19000r/min, the working temperature is -35-+80 degrees Celsius, and it is interchangeable with the German ROTEX coupling.The polyurethane elastomer is limited by the convex claw block, which can avoid internal deformation caused by impact and external deformation caused by centrifugal force; the large concave surface of the convex claw makes the surface pressure on the involute tooth very small, even if the tooth is overloaded , The teeth will not wear or deform. XL intermediate sleeve type star elastic coupling is a high-performance coupling, which focuses on the advantages of different structures of standard elastic couplings.

江苏XL connection intermediate sleeve type star elastic coupling Guangdong XL connection intermediate sleeve type star elastic coupling

FZ type double fulcrum square bottom plate rack

FZ type double pivot square bottom plate rack...

FZ type double fulcrum square bottom plate rack

FZ type double pivot square bottom plate rack...

Tire coupling for LLB metallurgical equipment

Tire coupling for LLB metallurgical equipment...

Tire coupling for LLB metallurgical equipment

Tire coupling for LLB metallurgical equipment...

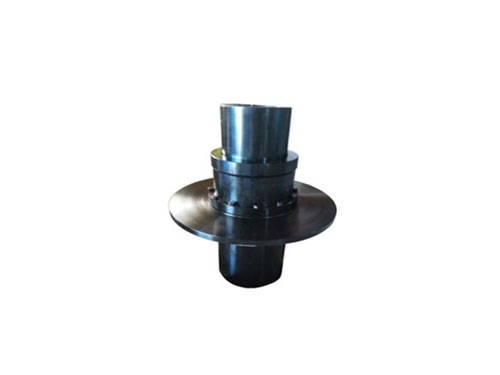

WGT type gear coupling with intermediate sleeve

WGT type connecting middle sleeve gear coupling...

WGT type gear coupling with intermediate sleeve

WGT type connecting middle sleeve gear coupling...

XL connection middle sleeve type star elastic coupling

XL connection middle sleeve type star elastic...

XL connection middle sleeve type star elastic coupling

XL connection middle sleeve type star elastic...