Tire coupling for LLA metallurgical equipmentThe tire coupling for LLA metallurgical equipment is...

Tire coupling for LLA metallurgical equipmentThe tire coupling for LLA metallurgical equipment is... GICL type-drum gear couplingGICL type-drum gear coupling (JB/T 88...

GICL type-drum gear couplingGICL type-drum gear coupling (JB/T 88... HL nylon rod pin couplingHL nylon rod pin coupling has good toughness...

HL nylon rod pin couplingHL nylon rod pin coupling has good toughness... WGT type gear coupling with intermediate sleeveWGT type connecting middle sleeve gear coupling is working...

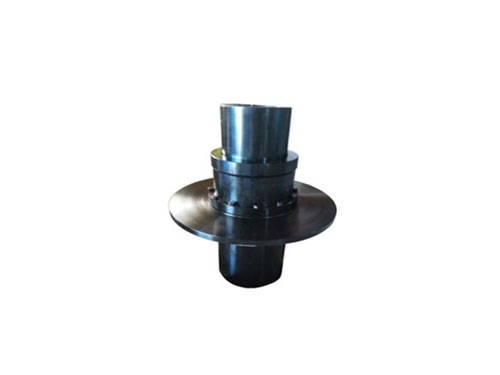

WGT type gear coupling with intermediate sleeveWGT type connecting middle sleeve gear coupling is working... WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth...

WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth...Inspection and description of coupling

Coupling inspection is a key link related to installation, use and life. Reasonable inspection in accordance with inspection procedures will help to provide work speed to avoid missed inspections and false inspections during production.Generally speaking, the inspection items of the coupling mainly include the following items:

XNUMX. Check the dimensional accuracy of the coupling

When checking the dimensional accuracy of the coupling, check the drawings, process and technical conditions.Generally, check the shape dimensions first, such as the shape, hole, shaft diameter, and then check the positioning dimensions, such as margins, center distances, etc.When inspecting parts with complex shapes and various sizes, a table should be drawn before the inspection, and the shape size should be listed in the table first, and then the positioning size should be listed in the table, and then measure according to the order of the table, and write the measurement results In the actual measured size column, so that the size will not be missed, and the inspection quality can be confirmed.

Most of the commonly used couplings have been standardized or standardized. Under normal circumstances, it is only necessary to correctly select the type of coupling and determine the type and size of the coupling.When necessary, the load capacity can be checked and calculated for the vulnerable weak links; when the speed is high, the centrifugal force of the outer edge and the deformation of the elastic element can be checked, and the balance check can be performed.

XNUMX. Measuring form and position error

When measuring form and position errors, pay attention to the measurement datum, and pay attention to the elements marked with the principle of tolerance and the principle of large entity.The diaphragm coupling is connected with the two halves of the coupling in a staggered manner with bolts. Each group of diaphragms is made up of several pieces. The diaphragms are divided into connecting rod type and whole piece type of different shapes.The diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the connected two shafts.Drum-shaped gear coupling shell mold molding simplifies the processing technology, low cost, the larger the tooth width, the larger the drum radius, the larger the backlash required, and it is commonly used in various hydraulic pumps, lubrication pumps, and pneumatics. Pumps, compressors, textile machines and other machinery.For the elements that are not marked with geometric tolerances on the paper, the inspectors can find the tolerance values and measure them according to the national or enterprise standards as needed.Such as the coaxiality, circular runout of the coupling, the symmetry of the keyway, the position of the hole and so on.

XNUMX. Check whether the materials used are up to standard

When inspecting parts, first check the specifications and grades of the materials used in the parts against the title bar of the drawing and the process documents, and check the grain direction and status of the plates.Couplings are also called couplings.A mechanical component used to firmly connect the driving shaft and the driven shaft in different mechanisms to rotate together and transmit motion and torque.Sometimes it is also used to connect shafts and other parts (such as gears, pulleys, etc.).Dimensional inspection is carried out after passing the test.

Fourth, check the shape, surface roughness and surface quality of several couplings

Compare the front view and other views to check whether the geometry of the coupling is qualified; check whether the position of each element is correct, such as holes, grooves, etc.; check surface roughness, surface quality, such as scratches, bumps, deformation, cracks, etc.

The heat treatment of the coupling is divided into preparation heat treatment (or pre-heat treatment) and final heat treatment (or post heat treatment). In modern industrial production, the heat treatment of the coupling has become an important technical regulation.This is due to the excellent mechanical functions of steel and certain alloys-high hardness, strength, elasticity and abrasion resistance, etc., in addition to the chemical composition required during smelting, it must be obtained by heat treatment afterwards. Therefore, in order to achieve technical It is important that we need to heat-treat the coupling in the process of producing the coupling.

The coupling indicates the required bolt tightening torque value. The vertical flange between the inner wheel and the spacer should use bolts for reaming holes and self-locking nuts, and the hole size tolerance zone is H8.The bolts should be limited to the quality range to avoid adverse effects on the balance of the coupling during interchange.When the buyer requires electrical insulation of the coupling, the coupling with spacer should be selected, and there should be electrical insulation on the flange joint surface and the bolt position.

联轴器零件的垂直法接合面,对旋转中心的端面圆跳动公差等级为6级,其他端面圆跳动公差等级为7级;配合面、导向面对旋转中心的径向圆跳动公差等级为6级;其他圆柱面的径向圆跳动公差等级为7级;配合面、导向面对旋转中心的同轴度公差等级为5级。

The heat treatment of the coupling is the operation technology of the metal or alloy in the solid range, through the cooperation of family, heat preservation, and cooling, so that the metal or alloy changes the internal arrangement and the required functions. The heat treatment of the coupling is the modern machinery industry, In the metallurgical industry, improving product quality and extending the service life of machine parts is an indispensable part.

The design of the coupling considers the axial displacement between the two to be connected, and its value should be greater than 6mm.When the coupling is installed, a compensation amount should be reserved in the direction of thermal expansion.The structure of the gear coupling without spacer sleeve should allow the gear sleeve to make an appropriate amount of axial movement, so that the inner and outer teeth can be separated from the mode, so as to check the working condition of the gear teeth and do not need to disassemble the coupling during equipment maintenance.The structure of the coupling should be aligned with all parts.The mating inner and outer teeth should be centered by the tooth top.In order to reduce potential imbalances, tooth circumferential backlash.