Star flexible coupling

Elastic sleeve pin coupling

Diaphragm coupling series

Elastic pin coupling

Drum type gear coupling series

Plum-shaped elastic coupling

Rigid coupling series

Tyre coupling series

Slider coupling series

Universal coupling series

Roller chain coupling

Water pump coupling

Various coupling accessories

Industrial expansion sleeve

Serpentine spring coupling accessories

Reducer bracket series

HL type elastic pin couplingThe elastic pin coupling uses a number of non...

HL type elastic pin couplingThe elastic pin coupling uses a number of non... XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame...

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame... Diaphragm coupling diaphragmDiaphragm couplings have a wide range of applications...

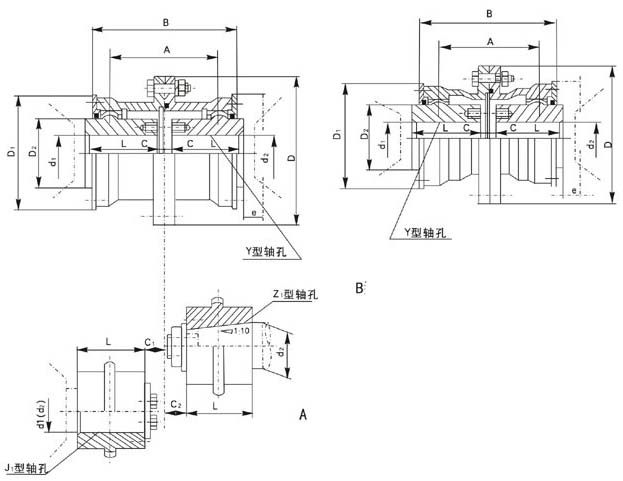

Diaphragm coupling diaphragmDiaphragm couplings have a wide range of applications...GICL type-drum gear coupling

GICL type-drum gear coupling (JB/T 8845. 3-2001) is a rigid-flexible coupling. The gear coupling is a semi-connected inner ring gear with the same number of teeth and a flange with outer teeth. It is composed of shafts and other parts.The external teeth are divided into straight teeth and drum teeth. The so-called drum teeth means that the external teeth are made into a spherical surface. The spherical surface is on the gear axis. The tooth side clearance is larger than that of ordinary gears. Drum gear couplings are allowed. Larger angular displacement (compared to straight tooth coupling) improves the torque transmission capacity and prolongs the service life.The contact state along the tooth width when there is angular displacement.It has the ability to compensate for axis deviation in radial, axial and angular directions, and has the advantages of compact structure, small turning radius, large carrying capacity, low transmission, low noise and long maintenance period. It is especially suitable for low-speed and heavy-duty working conditions, such as metallurgy, It is also suitable for shaft transmission of various machinery such as petroleum, chemical industry, general machinery, etc. in mining, lifting and transportation industries.

The characteristics of drum gear couplings (compared to straight gear couplings with the following characteristics) 1. Load bearing.Under the same outer diameter of the inner gear sleeve and the large outer diameter of the coupling, the load-bearing capacity of the drum gear coupling is 15-20% higher than that of the straight gear coupling on average; 2. Large angular displacement compensation.When the radial displacement is equal to zero, the allowable angular displacement of the spur gear coupling is 1º; while the allowable angular displacement of the drum gear coupling is 1º; 30”, an increase of 50%, in the same mold Under the condition of number, number of teeth, and tooth width, the allowable angular displacement of the drum-shaped tooth is larger than that of the straight tooth; 3. The drum-shaped tooth surface makes the inner side and avoids the disadvantages of the edge of the straight tooth end being squeezed under the condition of angular displacement and stress concentration. At the same time, the friction and wear conditions of the tooth surface reduce the noise and the maintenance cycle is long; 4. The tooth end of the outer gear sleeve is in the shape of a horn, which makes the assembly and disassembly of the inner and outer teeth easy. 5. The transmission reaches 99.7%.Based on the characteristics of the warp, at present, drum-shaped teeth have generally been substituted for straight-tooth couplings. The varieties of drum-shaped gear couplings produced by UMA meet the corresponding standards.Drum-shaped gear couplings are rigid, flexible, and inelastic, so they are not suitable for machinery that requires damping, buffering, and two-shaft alignment.

| model | Nominal torque Tn(N·m) | Allowable speed [n] (r/min) | Diameter of shaft hole d1, d2, dz | Length of shaft hole | D | D1 | D2 | B | A | C | C1 | C2 | e | Moment of inertia (kg·m2) | Weight(kg) | |

| Y | Z1,J | |||||||||||||||

| L | ||||||||||||||||

| GICL1 | 630 | 4000 | 16 18 19 | 42 | - | 125 | 95 | 60 | 115 | 75 | 20 | - | - | 30 | 0.009 | 5.9 |

| 20 22 24 | 52 | 38 | 10 | - | 24 | |||||||||||

| 25 28 | 62 | 44 | 2.5 | - | 19 | |||||||||||

| 30 32 35 38 | 82 | 60 | 15 | 22 | ||||||||||||

| GICL2 | 1120 | 4000 | 25 28 | 62 | 44 | 144 | 120 | 75 | 135 | 88 | 10.5 | - | 29 | 30 | 0.02 | 9.7 |

| 30 32 35 38 | 82 | 60 | 2.5 | 12.5 | 30 | |||||||||||

| 40 42 45 48 | 112 | 84 | 13.5 | 28 | ||||||||||||

| GICL3 | 2240 | 4000 | 30 32 35 38 | 82 | 60 | 174 | 140 | 95 | 155 | 106 | 3 | 24.5 | 25 | 30 | 0.047 | 17.2 |

| 40 42 45 48 50 55 56 | 112 | 84 | 17 | 28 | ||||||||||||

| 60 | 142 | 107 | 35 | |||||||||||||

| GICL4 | 3550 | 3600 | 32 35 38 | 82 | 60 | 196 | 165 | 115 | 178 | 125 | 14 | 37 | 32 | 30 | 0.091 | 24.9 |

| 40 42 45 48 50 55 56 | 112 | 84 | 3 | 17 | 28 | |||||||||||

| 60 63 65 70 | 142 | 107 | 35 | |||||||||||||

| GICL5 | 5000 | 3300 | 40 42 45 48 50 55 56 | 112 | 84 | 224 | 183 | 130 | 198 | 142 | 3 | 25 | 28 | 30 | 0.167 | 38 |

| 60 63 65 70 71 75 | 142 | 107 | 20 | 35 | ||||||||||||

| 80 | 172 | 132 | 22 | 43 | ||||||||||||

| GICL6 | 7100 | 3000 | 48 50 55 56 | 112 | 84 | 241 | 200 | 145 | 218 | 160 | 6 | 35 | 35 | 30 | 0.267 | 48.2 |

| 60 63 65 70 71 75 | 142 | 107 | 4 | 20 | 35 | |||||||||||

| 80 85 90 | 172 | 132 | 22 | 43 | ||||||||||||

| GICL7 | 10000 | 2680 | 60 63 65 70 71 75 | 142 | 107 | 260 | 230 | 160 | 244 | 180 | 4 | 35 | 35 | 30 | 0.453 | 68.9 |

| 80 85 90 95 | 172 | 132 | 22 | 43 | ||||||||||||

| 100 | 212 | 167 | 48 | |||||||||||||

| GICL8 | 14000 | 2500 | 65 70 71 75 | 142 | 107 | 282 | 245 | 175 | 264 | 193 | 5 | 35 | 35 | 30 | 0.646 | 83.3 |

| 80 85 90 95 | 172 | 132 | 22 | 43 | ||||||||||||

| 100 110 | 212 | 167 | 48 | |||||||||||||

| GICL9 | 18000 | 2350 | 70 71 75 | 142 | 107 | 314 | 270 | 200 | 284 | 208 | 10 | 45 | 45 | 30 | 1.036 | 110 |

| 80 85 90 95 | 172 | 132 | 22 | 43 | ||||||||||||

| 100 110 120 125 | 212 | 167 | 5 | 49 | ||||||||||||

| GICL10 | 31500 | 2150 | 80 85 90 95 | 172 | 132 | 346 | 300 | 220 | 330 | 249 | 5 | 43 | 43 | 30 | 1.88 | 157 |

| 100 110 120 125 | 212 | 167 | 22 | 49 | ||||||||||||

| 130 140 | 252 | 202 | 29 | 54 | ||||||||||||

| GICL11 | 40000 | 1880 | 100 110 120 125 | 212 | 167 | 380 | 330 | 260 | 360 | 40 | 6 | 29 | 49 | 40 | 3.28 | 217 |

| 130 140 150 | 252 | 202 | 54 | |||||||||||||

| 160 | 302 | 242 | 64 | |||||||||||||

| GICL12 | 56000 | 1680 | 120 125 | 212 | 167 | 442 | 380 | 290 | 416 | 313 | 6 | 57 | 57 | 40 | 5.08 | 305 |

| 130 140 150 | 252 | 202 | 29 | 55 | ||||||||||||

| 160 170 180 | 203 | 242 | 68 | |||||||||||||

| GICL13 | 80000 | 1530 | 140 150 | 252 | 202 | 482 | 420 | 320 | 476 | 364 | 7 | 54 | 57 | 40 | 10.06 | 419 |

| 160 170 180 | 302 | 242 | 32 | 70 | ||||||||||||

| 190 200 | 352 | 282 | 80 | |||||||||||||

| GICL14 | 112000 | 1300 | 160 170 180 | 302 | 242 | 520 | 465 | 360 | 532 | 415 | 8 | 42 | 70 | 40 | 16.774 | 594 |

| 190 200 220 | 352 | 282 | 32 | 80 | ||||||||||||

| GICL15 | 160000 | 1180 | 190 200 220 | 352 | 282 | 580 | 510 | 400 | 556 | 429 | 10 | 34 | 80 | 40 | 26.55 | 783 |

| 140 250 | 38 | - | ||||||||||||||

| GICL16 | 250000 | 1000 | 200 220 | 352 | 282 | 680 | 595 | 465 | 640 | 501 | 10 | 58 | 80 | 50 | 52.22 | 1131 |

| 240 250 260 | 410 | 330 | 38 | - | ||||||||||||

| 280 | 470 | 380 | 38 | |||||||||||||

| GICL17 | 280000 | 980 | 220 | 352 | 282 | 720 | 645 | 495 | 672 | 512 | 10 | 74 | 80 | 50 | 69 | 1305 |

| 240 250 260 | 410 | 330 | 39 | - | ||||||||||||

| 280 330 | 470 | 380 | ||||||||||||||

| GICL18 | 355000 | 900 | 240 250 260 | 410 | 330 | 775 | 675 | 520 | 702 | 524 | 10 | 46 | - | 50 | 96.19 | 1626 |

| 280 300 320 | 470 | 380 | 41 | |||||||||||||

| GICL19 | 450000 | 830 | 260 | 410 | 330 | 815 | 715 | 560 | 744 | 560 | 10 | 57 | - | 50 | 115.6 | 1773 |

| 280 300 320 | 470 | 380 | 41 | |||||||||||||

| 340 | 550 | 450 | ||||||||||||||

| GICL20 | 500000 | 790 | 280 300 320 | 470 | 380 | 855 | 755 | 585 | 786 | 595 | 13 | 44 | - | 50 | 167.41 | 2263 |

| 340 360 | 550 | 450 | ||||||||||||||

| GICL21 | 630000 | 750 | 300 320 | 470 | 380 | 915 | 795 | 620 | 808 | 611 | 13 | 59 | - | 50 | 215.7 | 2593 |

FCL type elastic sleeve pin coupling

FCL type elastic sleeve pin coupling...

FCL type elastic sleeve pin coupling

FCL type elastic sleeve pin coupling...

Tire coupling for LLA metallurgical equipment

Tire coupling for LLA metallurgical equipment...

Tire coupling for LLA metallurgical equipment

Tire coupling for LLA metallurgical equipment...

KC type sprocket coupling

KC series sprocket coupling is used...

KC type sprocket coupling

KC series sprocket coupling is used...

Three-jaw coupling for pump

The three-jaw coupling for pumps uses...

Three-jaw coupling for pump

The three-jaw coupling for pumps uses...