WF type non-telescopic flange universal couplingUniversal coupling is a kind of coupling,...

WF type non-telescopic flange universal couplingUniversal coupling is a kind of coupling,... Nylon sleeve inner gear ringThe main purpose of the nylon sleeve inner gear ring is:...

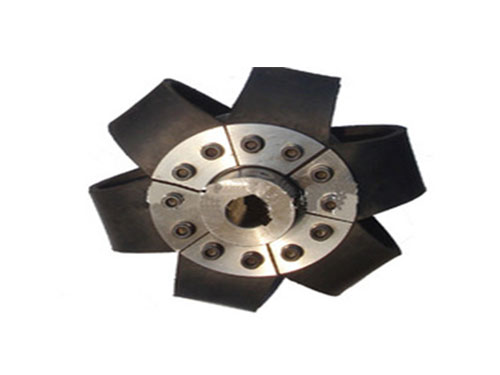

Nylon sleeve inner gear ringThe main purpose of the nylon sleeve inner gear ring is:... LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect...

LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect... Rigid couplingThe characteristics of rigid coupling: rigid coupling...

Rigid couplingThe characteristics of rigid coupling: rigid coupling... SWP-B type has telescopic short universal couplingDue to manufacturing, installation, load deformation and...

SWP-B type has telescopic short universal couplingDue to manufacturing, installation, load deformation and...Bolt connection and characteristics of diaphragm coupling

The diaphragm coupling bolt connection does not need to be threaded on the connecting piece, the use is not restricted by the connecting piece, the structure is simple, and the disassembly and assembly are convenient.Stud bolts can be used in occasions where bolts cannot be used due to structural restrictions, but a compact connection structure is required.The bolt connection does not have a nut and has a smooth exposed surface, but it is not suitable for frequent disassembly and connection to avoid damage to the threaded hole.

During the service life of the diaphragm coupling, it is necessary to maintain the wedge-shaped clearance surfaces that are inclined to each other, add lubricating oil, and exit from the large port into the small port.The two surfaces have sufficient relative movement speed, the fluid has sufficient viscosity, and sufficient oil is required.In the maintenance process, it is important to grasp the basic scope of hydrodynamic lubrication, which is also the theoretical basis of sliding bearing design.

Diaphragm coupling is one of the commonly used coupling parts for mechanical shaft transmission, used to connect two shafts (driving shaft and driven shaft) in different mechanisms, so that the two shafts can rotate together to transmit torque.In modern mechanical transmission devices, the coupling is required to have good dynamic response performance, while transmitting large torque, relatively good transmission angle accuracy, and easy to disassemble and install, and connect.Therefore, the development of a new type of coupling with small moment of inertia, high speed, good damping performance, and good centering compensation ability is one of the main issues that machinery needs to solve at present.

Diaphragm couplings began to be used abroad in the 1671s and developed rapidly. A certain country has included it in the AP147 standard. Many of them are commonly used in various areas, such as fans, pumps, compressors, and chemical fiber equipment.It plays an important role in improving equipment performance, saving energy and reducing consumption, and reducing vibration.Practice has proved that it not only has a large power reweight, but also has achieved a record of 45000kW/min in power and XNUMXr/min in speed after hundreds of thousands of hours of trouble-free operation.It fully embodies the advantages of this coupling and makes its application more and more common.

Features of diaphragm coupling:

【1】Zero rotation gap;

【2】It has oil resistance and characteristics;

[3] The stainless steel diaphragm absorbs vibration and compensates radial, angular and axial deviations;

[4] The characteristics of clockwise and counterclockwise rotation are the same;

【5】Material: aluminum alloy;

[6] The keyway can be processed according to customer needs.Metric or imperial size aperture.Integrated design, often used in machine tool platform, stepping servo system, screw spindle drive;

[7] High torque rigidity and high sensitivity, high torque load.

The characteristics and composition of the diaphragm of the diaphragm coupling

[1] Features of the formed diaphragm: each coupling is composed of a single diaphragm, and the thickness of the diaphragm is regularly reduced from the inner to the outer hyperbola to maintain the same strength conditions. The material utilization rate is good, and the integrity is good, especially It is suitable for transmission, but the manufacturing precision of the diaphragm is relatively good.

[2] Features of separate connecting rod shape: each diaphragm is composed of a single thin rod to form a polygon. The rod has a simple shape and is convenient to manufacture, but requires the pitch of each hole. Its working performance is basically the same as that of a continuous polygonal ring, but its strength and speed are lower. Low, suitable for occasions where the coupling size is affected.

[3] The characteristics of the spoke shape: each coupling is composed of several pieces, and the screw holes on the outer and inner edges are respectively connected with the driving and driven half couplings, which are twisted during operation, and the formed holes on the diaphragm are In order to increase elasticity, the difference between the inner and outer diameters should not be too small due to elasticity, and it is generally appropriate to transmit medium and small power.

[4] Features of the wave-shaped diaphragm: The diaphragm is wave-shaped in the axial section, with good elasticity and good compensation performance.The thickness of the diaphragm has the same thickness and unequal thickness of the single-piece hyperbolic type, which has good performance and is used in many applications.

The diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the two shafts connected. It is a flexible coupling with strong metal components. It does not require lubrication, has a compact structure, good service life, no rotation, and no Affected by temperature and oil pollution, it is suitable for shafting transmission in high temperature and corrosive environment.Special attention should be paid to this key problem of left and right, so everyone should pay special attention to this kind of problem when using and installing and disassembling. It can increase the life of the coupling and prevent it from being more serious. The common faults and damages can make the actual effect of the diaphragm coupling more complete, and can also prevent the damage to its full normal function.If an error occurs, the active end or the driven end need to be re-aligned.First find out the part with large offset error, this must first measure which side of the coupling is offset, that is, measure the level and coaxiality of the main shaft and the level and coaxiality of the reducer main shaft, and re-copy according to the quality scale. The fault can be removed by leveling and aligning.