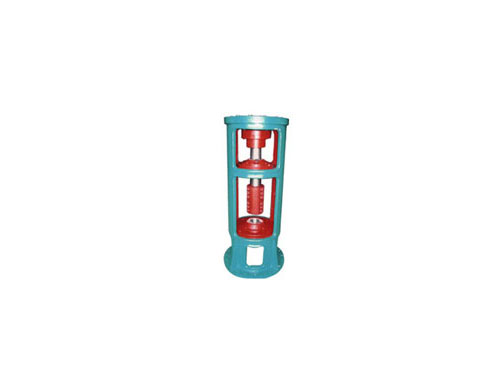

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame...

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame... SWP-E type cross shaft universal couplingSWP-E type cross shaft universal coupling is used to...

SWP-E type cross shaft universal couplingSWP-E type cross shaft universal coupling is used to... HLL type brake wheel elastic pin couplingHLL type brake wheel elastic pin coupling has...

HLL type brake wheel elastic pin couplingHLL type brake wheel elastic pin coupling has... WGT type gear coupling with intermediate sleeveWGT type connecting middle sleeve gear coupling is working...

WGT type gear coupling with intermediate sleeveWGT type connecting middle sleeve gear coupling is working... GLF roller chain couplingGLF roller chain coupling is suitable for hydraulic machinery...

GLF roller chain couplingGLF roller chain coupling is suitable for hydraulic machinery...Performance requirements for couplings of wind turbines

XNUMX. Transmission accuracy

The coupling of a wind turbine is mainly used to transmit power, but it has relatively good requirements for transmission accuracy.During this period, not only must avoid non-metal elastic elements, but also avoid gaps between movable elements.Under this condition, the high-speed rotation process is prevented, and the coupling is prevented from being damaged.

XNUMX. The relative displacement of the connected two shafts

The two shafts of the coupling are affected by related factors such as manufacturing errors, installation errors, and deformations, and they will all produce displacement, especially the form of movement between components.The generator in the wind may exist for a long time during the paired operation, which is likely to cause the elastic support to continue to fail, thereby causing vibration under wind speed conditions.The manifestation of this phenomenon is different from the influence of generators and gearboxes. The displacement phenomenon generated on the axis cannot be controlled. To some extent, the displacement between the two shafts cannot be avoided. Under different operating conditions, Relevant factors such as the magnitude of the displacement of the shaft transmission will also be different.

According to the above research and discussion of related phenomena, wind turbines are easy to change their working characteristics under the corresponding operating environment, so some conditions must be considered during the selection of the coupling.For example, the selection of transmission accuracy is relatively good.Not only should it be selected within a reasonable temperature range, but also the one that has the ability to prevent corrosion and oil to prevent slipping.

XNUMX. Working environment

The actual working environment of wind turbines is relatively harsh. According to the distribution of wind energy resources in my country, the areas where wind energy has been produced and the areas where wind energy is about to be produced are all located in coastal areas. Second, salt fog often occurs in coastal areas. The surrounding environment is relatively humid. XNUMX. Under this condition, the related parts of the fan are prone to rust and aging. XNUMX. Moreover, in some mountainous areas, due to unstable settlement and rising airflow phenomena, it is easy to produce relatively good airflow.

Four, load category

The load category is different according to the working load impact, vibration, braking and other reasons of the unit.Because different couplings have different load-bearing capabilities, the load of the coupling on the wind turbine generator is mainly affected by the impeller, gearbox and generator.If the coupling is affected by its own center of mass and inertial axis, it will also produce an unbalanced state of centrifugal inertia during operation.These factors not only affect the normal operation of the coupling, but also affect the selection index of the coupling.

The diaphragm of the diaphragm coupling is fastened to the shaft sleeve with a pin. Generally, it will not loosen or cause backlash between the diaphragm and the shaft sleeve. This characteristic is a bit like a bellows coupling. In fact, the coupling transmits The way of torque is similar.The diaphragm itself is very thin, so it is easy to bend when the relative displacement load is generated, so it can withstand up to 1.5 degrees of deviation, while generating a lower bearing load in the servo system.The diaphragm coupling can be adapted to work in high temperature (-80+300) and harsh environments, and can move under shock and vibration conditions.

Diaphragm couplings can easily be damaged if they are misused in use or not installed correctly.Therefore, it is especially important to determine that the deviation is within the tolerance range of the normal operation of the coupling.

Diaphragm coupling mother body manufacturing.The choice of the matrix material of the diaphragm coupling is very important. Generally, the 45# or 40CR forging material should be selected and the rough machining should be carried out after normalizing treatment. After the rough machining, the quenching and tempering treatment should be carried out to determine the overall coupling material The mechanical performance reaches its performance state. After quenching and tempering, the finishing process is performed, and the mechanical dynamic balance test is required after finishing. The particularly important diaphragm coupling is also subjected to nitriding treatment to determine the transmission strength of the coupling matrix.

In addition, it is the selection and manufacture of diaphragm material. The diaphragm material must have high strength and fatigue, and good processing performance, corrosion resistance and heat resistance. At present, it is mainly made of stainless steel and other alloys such as 1CR18NI9 and 1CR18NI9TI.

However, because the difference of diaphragm materials directly affects the performance, service life and cost of diaphragm couplings (frequently changing diaphragms), and the price of diaphragm materials is very different, there are equivalent diaphragm couplings on the market It is made of low-cost materials.