Star flexible coupling

Elastic sleeve pin coupling

Diaphragm coupling series

Elastic pin coupling

Drum type gear coupling series

Plum-shaped elastic coupling

Rigid coupling series

Tyre coupling series

Slider coupling series

Universal coupling series

Roller chain coupling

Water pump coupling

Various coupling accessories

Industrial expansion sleeve

Serpentine spring coupling accessories

Reducer bracket series

NGCL type drum gear coupling with brake wheelNGCL type drum gear coupling with brake wheel...

NGCL type drum gear coupling with brake wheelNGCL type drum gear coupling with brake wheel... Expansion coupling sleeveCompared with the key connection, the expansion sleeve connection has...

Expansion coupling sleeveCompared with the key connection, the expansion sleeve connection has... DJM expansion sleeve diaphragm couplingDJM expansion sleeve diaphragm coupling strength JZMJ type...

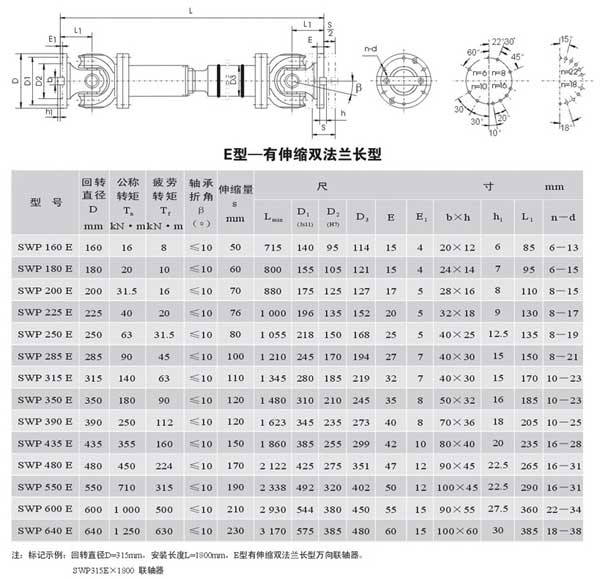

DJM expansion sleeve diaphragm couplingDJM expansion sleeve diaphragm coupling strength JZMJ type...SWP-E type cross shaft universal coupling

SWP-E type cross shaft universal joint is used to connect two shafts (active shaft and driven shaft) in different mechanisms to make them rotate together to transmit torque mechanical parts.In high-speed and heavy-duty power transmission, some couplings also have the function of buffering, damping and improving the dynamic performance of the shafting.The coupling is composed of two halves, which are respectively connected with the driving shaft and the driven shaft.The general power machine is mostly connected with the working machine by means of a coupling.

Rigid movable couplings use the dynamic connection between the working parts of the coupling to have a certain direction or several directions of mobility to compensate, such as jaw coupling (allowing axial displacement), cross groove coupling (Used to connect two shafts with small parallel or angular displacement), universal coupling (used in places where the two shafts have a large deflection angle or a large angular displacement during work), gear coupling (Comprehensive displacement allowed), chain couplings (radial displacement allowed), etc., elastic movable couplings (referred to as elastic couplings) use the elastic deformation of elastic elements to compensate for the deflection and displacement of the two shafts, and at the same time Elastic elements also have buffering and damping properties, such as serpentine spring couplings, radial multilayer leaf spring couplings, elastic ring pin couplings, nylon pin couplings, rubber sleeve couplings, etc. .Some couplings have been standardized.When choosing, you should first select the appropriate type according to the work requirements, and then calculate the torque and speed according to the diameter of the shaft, and then find out the applicable model from the relevant manuals, and check some key parts.

There are many types of couplings, according to the relative position and position changes of the two shafts connected, they can be divided into:

①Fixed coupling.It is mainly used in places where two shafts require strict alignment and no relative displacement occurs during work. The structure is generally simple, easy to manufacture, and the instantaneous speed of the two shafts is the same, mainly including flange couplings, sleeve couplings, and clamps Shell couplings, etc.

②Removable coupling.It is mainly used where the two shafts are deviated or have relative displacement during work. According to the method of compensating displacement, it can be divided into rigid movable coupling and elastic movable coupling.

HL nylon rod pin coupling

HL nylon rod pin coupling...

HL nylon rod pin coupling

HL nylon rod pin coupling...

T type plum blossom hexagonal water pump counter wheel pad

T-shaped plum blossom hexagonal water pump counter wheel pad...

T type plum blossom hexagonal water pump counter wheel pad

T-shaped plum blossom hexagonal water pump counter wheel pad...

LTZ elastic sleeve pin coupling with brake wheel

LTZ (formerly TLL type) with brake...

LTZ elastic sleeve pin coupling with brake wheel

LTZ (formerly TLL type) with brake...

XS type double fulcrum rack

Arrangement in the XS type double pivot rack...

XS type double fulcrum rack

Arrangement in the XS type double pivot rack...