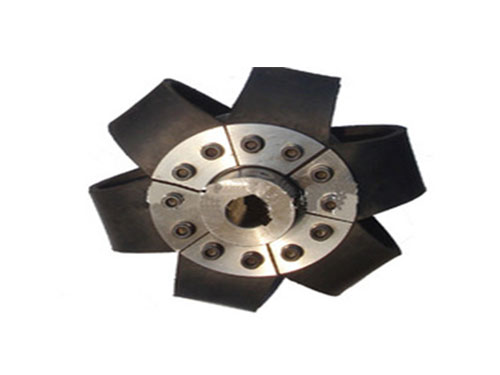

ML plum-shaped elastic couplingML plum-shaped elastic coupling and other coupling...

ML plum-shaped elastic couplingML plum-shaped elastic coupling and other coupling... LMS type double flange type plum blossom elastic couplingLMS (formerly MLS) type-double-flange...

LMS type double flange type plum blossom elastic couplingLMS (formerly MLS) type-double-flange... LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect...

LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect... ZLL type elastic pin gear coupling with brake wheelZLL type elastic pin gear coupling with brake wheel...

ZLL type elastic pin gear coupling with brake wheelZLL type elastic pin gear coupling with brake wheel... Roller chain couplingRoller chain couplings can be used in textiles, agriculture...

Roller chain couplingRoller chain couplings can be used in textiles, agriculture...The universal coupling uses common sense to connect with the tooth surface of the gear coupling

The correct use of universal couplings can extend the life. It is strictly forbidden to start the car with gears; it is strictly forbidden to lift the clutch pedal; it is strictly forbidden to overload or overspeed the vehicle; the working condition of the transmission shaft should be checked frequently; the fastening of the transmission shaft hanger should be checked frequently, Whether the supporting rubber is damaged, whether the connecting parts of the transmission shaft are loose, whether the transmission shaft is deformed; in order to determine the dynamic balance of the transmission shaft, you should always pay attention to whether the balance welding piece is unsoldered.

The new drive shaft assembly is provided as a complete set. When installing the new drive shaft, pay attention to the assembly mark of the telescopic sleeve, and make sure that the flange fork is in a plane.When repairing and disassembling the drive shaft, the assembly mark should be printed on the telescopic sleeve and the flange shaft to keep the original assembly relationship unchanged during reassembly; grease should be added to the universal joint cross bearing frequently, and No. 3 should be injected in summer Lithium-based grease, inject No. 2 lithium-based grease in winter.

The vibration of the universal coupling is a fault that needs to be resolved. The vibration of the universal coupling may be compensated by the balance sheet or component on the universal coupling that has not stopped moving; The universal joints are not in the same plane; the universal joint is bent, the shaft tube is recessed, the logo is not aligned when the drive shaft is assembled, or the universal joint fork and spline shaft are tilted when welding with the shaft tube, which is destroyed The dynamic balance of the original; the joint bolts of the universal joint flange plate are loose, causing the position of the universal joint to be skewed; the spline of the universal joint spline shaft and the sleeve fork is worn out, and the gap is too large.

The drum tooth of the gear coupling is to make the outer tooth into a spherical surface, the center of the spherical surface is on the gear axis, and the tooth side clearance is larger than that of ordinary gears.The gear coupling can allow a large angular displacement relative to the straight gear coupling.And the contact conditions of the teeth are improved, so that the ability to transmit torque is improved, and the service life of the coupling is prolonged.Clearance fit directly affects the service life of the coupling.The gap between the circumference and the hole has a corresponding size fit according to the standard, that is, the degree of accuracy.

The gap between the connecting piece and the coupling will not only affect the product damage life, but also bring about the transmission performance of the entire equipment, and the rigid coupling will also cause noise.And the length of the coupling gap and other problems, if the transmission parts move back and forth when the mechanical equipment is running, the friction will be brought about, the damping pad plum coupling, the star coupling, the protruding friction will double the damage to the connection pad .If it is determined that the drum gear coupling is working, good lubrication can slow down the wear.Drum-shaped gear couplings are mostly lubricated by lubricating oil, and the lubricating oil needs to be filtered by a good-precision oil filter with a filtration degree of less than 10 microns.

The tooth surface requires continuous lubrication, otherwise the temperature of the tooth surface will rise and water and dirt will accumulate. Some drum-shaped gear couplings sometimes use the structure of the oil collecting groove, that is, the oil collecting groove is machined in the outer gear shaft hole, and the oil collecting groove is machined in the outer gear shaft hole. The bottom of the tooth groove is drilled with an oil hole that communicates with the oil collecting groove. In order to make it sufficiently lubricated, we use the centrifugal force generated by the operation of the gear coupling to spray oil into the meshing part of the inner and outer teeth.Gear coupling is composed of internal gear ring with the same number of teeth and flange half coupling with external teeth.The external teeth are divided into straight teeth and drum teeth. The so-called drum teeth means that the external teeth are made into a spherical surface. The center of the spherical surface is on the gear axis. The tooth side clearance is larger than that of ordinary gears. The drum-shaped gear coupling can Allow large angular displacement.