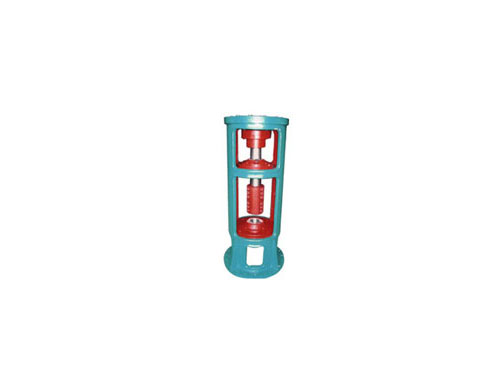

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame...

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame... Multi-section clamping diaphragm coupling1. Diaphragm elastic coupling 2. Gaoling...

Multi-section clamping diaphragm coupling1. Diaphragm elastic coupling 2. Gaoling... Slider couplingSlider couplings are often used in general...

Slider couplingSlider couplings are often used in general... XL connection middle sleeve type star elastic couplingXL connection middle sleeve type star elastic coupling...

XL connection middle sleeve type star elastic couplingXL connection middle sleeve type star elastic coupling... GLF roller chain couplingGLF roller chain coupling is suitable for hydraulic machinery...

GLF roller chain couplingGLF roller chain coupling is suitable for hydraulic machinery...Applicable environment of diaphragm coupling and installation of plum blossom coupling

Diaphragm coupling has applicable environment and principle introduction:

one,Diaphragm couplingIt consists of two coupling halves and a stainless steel coupling diaphragm in the middle. The principle is to adjust the misalignment of the two couplings through the three-dimensional deformation of the stainless steel diaphragm. Because the coupling is connected, it does not require lubrication and oil pollution. , Has good impact, and is also one of the couplings of dyeing machinery.

XNUMX. Diaphragm couplings are commonly used in shaft transmission of various mechanical devices, including textile machinery.The dye liquor for textile circulates in the circulation system of the dyeing machine, and the circulation pump is driven by the motor through the coupling.

XNUMX. Diaphragm coupling is suitable for the relative displacement of the two shafts in operation, the starting frequency is high, the occasions are often forward and reverse, and the load and speed change. It can adjust the shaft angle error that occurs during operation, which is beneficial to compensate the motor. The center deviation and axial movement between the reducer and the reducer.

XNUMX. Diaphragm couplings and tire couplings can be used not only in dyeing equipment, but also in textile equipment such as flat washing machines and cloth washing machines.

Although the diaphragm coupling is a small component, it has a function that other components cannot match. First, it can be used to connect motors, reducers and motor shafts.And can transmit torque.

Diaphragm coupling is suitable for corrosive media: Diaphragm coupling relies on the elastic deformation of the diaphragm to compensate the relative displacement of the connected two shafts. It is a high-performance flexible coupling with metal elastic elements and does not require lubrication. The structure is compact, the strength is good, the service life is long, there is no rotation gap, and it is not affected by temperature and oil pollution.

Some details of the installation of the plum blossom coupling are not very clear. Here is a brief introduction for you:

1、用百分表检测两半联轴节法兰盘端面和外圆跳动,当法兰盘外圆小于250mm时跳动值应不大于0.05mm;当法兰盘外圆大于250mm时,跳动值应不大于0.08。

2. Install the bolts: insert the bolts from the outside of the small hole of the flange, pass through the outside of the large hole of the other flange, put on the buffer sleeve, elastic washer, twist the nut, and tighten the nut with a wrench.If the installation is unsuitable or dismantle and replace without damaging the shaft and the half coupling, it is better to rotate freely after installation.

3. Instructions for the operator: Before starting the equipment, check whether the nut of the plum coupling is loose or falling off. If so, tighten the nut with a wrench in time.

4. Before installation, check whether the two shafts of the prime mover and the working machine are concentric, whether there are wrapping paper and scratches on the surfaces of the two shafts, whether there are debris in the inner holes of the two half couplings of the plum coupling, and whether the edges of the inner holes are If there are bruises, the shaft and half coupling should be cleaned up, and the bruises should be treated with a fine file.Then check whether the inner hole diameter and length of the two half couplings are consistent with the diameter and shaft elongation of the prime mover and working machine.In general selection, it is better to make the length of the prime mover and the working machine end half-coupling less than the shaft extension of 10-30mm.

5. In order to facilitate the installation, it is better to put the two half couplings in the 120150 thermal insulation box or oil tank for preheating, so that the inner hole size increases and it is easy to install.After installation, make sure that the shaft head cannot protrude from the end face of the half coupling, and it is better to be flush.Detect the distance between the two halves of the coupling: 34 points of readings measured along the two inner sides of the flange of the half coupling are averaged, and the sum of the measured dimensions of the extension and the two diaphragm sets is controlled by the error. Within the range of 0-0.4mm.

When using the zero-clearance claw coupling, the user should pay attention not to exceed the large bearing capacity of the elastic element given by the manufacturer (under the premise of determining the zero-clearance), otherwise the quincunx elastic spacer will be squashed and deformed and lose its elasticity , The preload disappears, resulting in the loss of zero-gap performance, and the user may only find out after a serious problem occurs.The plum blossom elastic spacer has multiple leaf branches. Like a slider coupling, it also squeezes the plum blossom elastic spacer to match the sleeves on both sides, and thus determines its zero clearance performance.Different from the slider coupling, the plum blossom coupling is driven by squeezing while the slider coupling is driven by shear.