Expansion coupling sleeveCompared with the key connection, the expansion sleeve connection has...

Expansion coupling sleeveCompared with the key connection, the expansion sleeve connection has... GL type roller chain couplingGL-type roller chain coupling AUTOCAD renderings...

GL type roller chain couplingGL-type roller chain coupling AUTOCAD renderings... LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect...

LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect... Serpentine spring couplingThe serpentine spring coupling is divided into one...

Serpentine spring couplingThe serpentine spring coupling is divided into one... NGCL type drum gear coupling with brake wheelNGCL type drum gear coupling with brake wheel...

NGCL type drum gear coupling with brake wheelNGCL type drum gear coupling with brake wheel...The problem of the wrong coupling of the fan and the motor and the fixing method of the H-type elastic block coupling

How to deal with the misalignment of fan and motor coupling

The fan and the motor are connected by a coupling to transmit movement and torque.The main coupling types include pin couplings or diaphragm couplings.Misalignment is a common failure of fans, and 60% of fan failures are related to misalignment.The misalignment fault of the fan refers to the degree of inclination or deviation between the axis line of the two rotors of the fan and the motor and the center line of the bearing.The main reasons for the misalignment of the fan rotor system:

(1) The bearing air gap is too large or the ball is slightly corroded. This situation is generally caused by insufficient lubrication or poor oil quality. This situation can easily cause misalignment and vibration. The bearing should be replaced according to the situation.

(2) Long-term vibration of the bearing seat causes deviation.Vibration of a large fan is inevitable, so it is easy to cause the base fastening bolts to loosen slightly, and the consequence is to cause misalignment and vibration.

Bearing seat installation standard: the limit deviation of the longitudinal and transverse centerline of the bearing seat is ±0.5mm.The horizontal tolerance of the bearing seat is 0.1/1000.The longitudinal levelness of the two bearing housings shall be based on the axial levelness of the rotor in the later stage.The bearing seat and the base bolts should be tightly fitted after being tightened, and check with a 0.05mm feeler gauge to not be inserted.

(3) Caused by the main motor itself.Large motors have relatively good requirements for dynamic balance. Due to various reasons, the dynamic balance of the motor itself is damaged and misalignment is required after long-term operation.After the fan rotor system has a misalignment fault, a series of dynamic effects that are unfavorable to the operation of the equipment will be generated during the rotation process, which will cause the deflection of the coupling, the wear of the bearing, the steady state of the oil film and the deflection and deformation of the shaft. The force and the additional force on the bearing cause the abnormal vibration of the fan and the early damage of the bearing, which is very harmful.For the fan misalignment fault.

At present, we generally adopt primitive methods to deal with it.First find the level of the main shaft of the fan, and rotate the impeller to make sure that the level deviation of the main shaft of the fan at each point is within the range; then find the alignment of the fan and the motor coupling, generally using a dial indicator, divided into 4 Check the beating degree of the point and confirm that the beating degree of 4 points is within the technical range, so that the middle degree is basically found.The solution can be solved with a laser alignment instrument, which is convenient.

Causes of failures that cause fan vibration

Analyzing the phenomenon and causes of fan failures, there are rules to follow. Generally speaking, there are the following types:

(1) Reasons for operation and operation: During the use of the fan, the maintenance and maintenance of the fan plays a decisive role in the operation quality of the fan.Such as: process parameters (such as medium temperature, pressure, flow, load, etc.) deviate from the design value, the machine operating conditions are abnormal; the machine runs under excessive speed or overload, which changes the working characteristics of the machine; poor lubrication or cooling; Partial damage or scaling of the rotor; improper operation during start-up and shutdown or speed-up/down, uneven thermal expansion, or staying in the critical zone for too long, etc.

(2) Reasons for machine deterioration: general equipment has a corresponding age limit when in use, and the performance of the equipment reaches a certain age limit.The same is true for fans, such as: long-term operation, the rotor deflection increases or the dynamic balance deteriorates; the rotor is partially damaged, peeled off or cracked; parts are worn, pitted or corroded, etc.; the force of the mating surface is deteriorated, resulting in insufficient interference Or loosening, etc., destroying the matching properties and accuracy; the machine foundation has uneven settlement, and the machine shell is deformed.

(3) Design reasons: The design of the fan is generally designed according to the use environment, temperature, air volume, wind pressure, medium, etc. of the fan, and some companies do not select all types based on these factors, resulting in the following factors: The fan design is improper, the dynamic characteristics are poor, and vibration occurs during operation; the structure is unreasonable and the stress is concentrated; the design working speed is close to or falls into the critical speed zone; the calculation of thermal expansion is inaccurate, resulting in poor thermal alignment.

(4) Manufacturing reasons: The quality requirements of the fan manufacturer also affect the operation of the fan, such as: poor parts processing and manufacturing, insufficient precision; poor parts material, insufficient strength, manufacturing defects; rotor dynamic balance does not meet technical requirements, etc.

(5) Reasons for installation and maintenance: The installation accuracy requirements of the fan play a vital role in the operation of the fan. If the installation accuracy does not meet the installation requirements, it will play a destructive effect on the operation of the fan.During the installation of the fan, there are the following influencing factors, such as: improper mechanical installation, misalignment of parts, large preload; poor shaft alignment; improper adjustment of machine geometric parameters (such as fit clearance, interference, and relative position); Improper placement of the rotor for a long time has changed the accuracy of dynamic balance; failure to maintain the machine in accordance with the regulations has destroyed the original matching properties and accuracy of the machine.

Vibration caused by abnormal coupling

Because the shaft of the induced draft fan and the motor are not concentric, or there is no gap between the induced draft fan and the motor coupling, it will also cause severe vibration of the bearing seat and the motor.Its vibration characteristics are:

(1) There is also obvious vibration on the side of the motor output shaft. Disconnect the induced draft fan and the motor coupling, the motor runs alone, and the vibration disappears.The method to deal with this kind of vibration: realign the center of the coupling and adjust it to reduce the misalignment of the induced draft fan and the motor shaft; reasonably reserve the gap between the induced draft fan and the motor coupling.

(2) The vibration is unstable. As the load changes, the amplitude is small when idling and large when fully loaded. The greater the axis deviation, the greater the vibration.

For the assembly of rigid coupling, the radial displacement of the two shaft centers shall not be greater than 0.03mm, and the contact between the end faces of the two half couplings should be close.

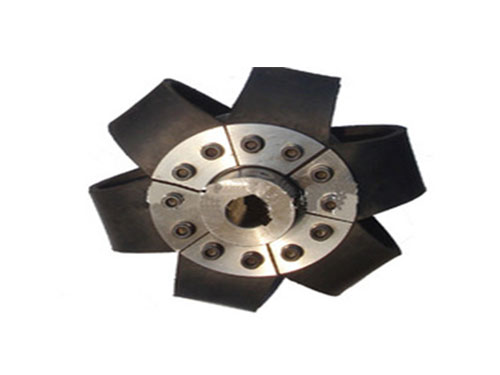

Fixing method of H-type elastic block coupling

XNUMX. H-shaped elastic block coupling fixed with D-shaped hole: Normally, if the shaft of the motor is D-shaped, if the positioning screw cannot be fixed, the hole of the coupling can be processed to correspond to the size of the motor shaft The D-shaped hole is fixed with the positioning screw, so there is no need to worry about slipping.

XNUMX. Fixing of the expansion sleeve: tightening and fixing the account cover by tightening the four positioning screws on the end of the coupling. It is suitable for the connection and fixing of some stepping motors and servo motors with large torque, such as expansion sleeve diaphragm couplings. , Expansion sleeve plum coupling, expansion sleeve bellows coupling, expansion sleeve H-type elastic block coupling, etc.

90. H-type elastic block coupling positioning screw fixation: the two positioning screws have a gap of XNUMXº to lock the fixed shaft. The old-fashioned fixing method, because the front end of the screw contacts the shaft center, may cause damage to the shaft center or Difficult to disassemble.

XNUMX. H-type elastic block coupling clamping screw fixation: Utilize the tightening force of the hexagon socket bolt to shrink the slit and clamp the shaft tightly.This method is convenient to fix and disassemble, and will not cause damage to the shaft, so it is a very common fixing method.

XNUMX. H-type elastic block coupling keyway type fixation: suitable for high-torque transmission. In order to prevent axial sliding, it is usually used together with set screw fixation and clamping screw fixation.