XL connection middle sleeve type star elastic couplingXL connection middle sleeve type star elastic coupling...

XL connection middle sleeve type star elastic couplingXL connection middle sleeve type star elastic coupling... GR-shaped coupling elastic bodyGR-shaped coupling elastic body and star-shaped elastic...

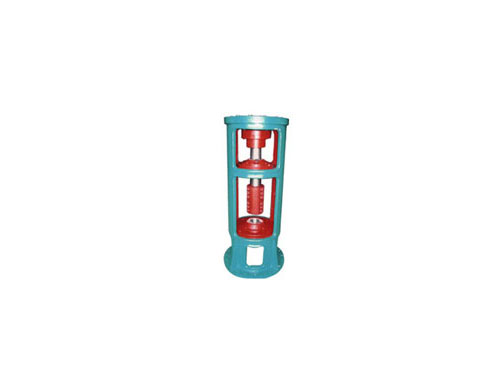

GR-shaped coupling elastic bodyGR-shaped coupling elastic body and star-shaped elastic... XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame...

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame... GLF roller chain couplingGLF roller chain coupling is suitable for hydraulic machinery...

GLF roller chain couplingGLF roller chain coupling is suitable for hydraulic machinery... XL type star elastic couplingXL type star elastic coupling and other coupling...

XL type star elastic couplingXL type star elastic coupling and other coupling...What equipment is needed for the application of diaphragm coupling?

In the actual working process of the diaphragm coupling, when they are working, especially during the entire rotation, there is no gap at all. This is a particularly important point, and this is also what they are in the process of processing. One needs to be determined, and all diaphragm couplings will undergo related inspections before they leave the factory.Diaphragm couplings will have particularly excellent elasticity, which means that to some extent, in the process of absorption or installation, diaphragm components will be produced in the form of three-dimensional deformation to withstand the misalignment of the driving and driven flanges.

In the process of hot-loading, if their temperature rises to XNUMX degrees Celsius, some personnel on site should pay attention to stability. In addition, for such a product, the temperature should be well adjusted while actually being assembled. In addition, it is necessary to make a series of records of the entire temperature through various different methods. Under this recording mode, there will be various current values. Similarly, their span should not exceed each liter. Thirty degrees Celsius, and this kind of leapfrogging mode is relatively recognized by more people.

What equipment is needed for the application of diaphragm coupling?

(1) Compressors, fans, and pumps, as basic fluid conveying machinery, are widely used in various types of production, and as couplings that connect such equipment to motors, they play a particularly critical role in operation. .Pump couplings are basically classified into these categories. Pumps are one of the most commonly used chemical machines. Medium and small pumps generally use elastic couplings.

(2) Centrifugal compressors-generally use gear couplings.Expansion sleeve gear coupling.The working principle of pump coupling, gear coupling refers to the transmission of torque by the meshing of inner and outer gear teeth.Because the semi-coupling's external tooth tip is processed into a spherical surface, the center of the spherical surface should be located on the axis, and the meshing teeth have a large tooth side clearance, so that it has a good ability to compensate for the displacement of the two shafts in any direction.

(3) When the fan is driven by a coupling, small and medium-sized centrifugal blowers often use elastic couplings, such as elastic sleeve pin couplings, nylon pin couplings, and diaphragm couplings.For high power, gear couplings are used.

(4) If the external gear is modified into drum teeth, it is more conducive to increase the coupling's ability to compensate for the comprehensive displacement.Slowly, it has replaced the conservative rubber strap as the bottom of the seat. The snake spring is located on the sofa seat frame and fixed with a snake spring buckle. It has good elasticity and long life. The cushion can be adjusted at will. The snake spring is an important part of the sofa structure. It is also called S spring. The extension spring has tensile properties because of its shape resembling the letter S.

(5) Generally, compressors with medium and low power use elastic couplings, such as elastic sleeve pin couplings, elastic pin couplings, diaphragm couplings; large symmetrical balanced medium and high pressure compression For example, a hydrogen-nitrogen compressor in a synthetic ammonia plant has high power and low speed. It is generally directly driven by a synchronous motor. The motor shaft and the compressor crankshaft use flange couplings; high-speed compressors also use gear couplings.

The diaphragm, as the key elastic element of the diaphragm coupling, bears the main load during operation.The misalignment forms that the diaphragm coupling can compensate include the following three basic types: angular (the center lines of the two shafts intersect at the midpoint between the ends of the two shafts at an angle), transverse (the center lines of the two shafts are offset in parallel) and Axial (excessive axial clearance between the two shafts).The actual offset that occurs during the operation of the rotating shaft system is often a combination of any of the above two types of misalignment or three types of misalignment at the same time, so the load and deformation of the diaphragm coupling during actual work are more complicated.

The difference between the single diaphragm coupling and the double diaphragm coupling is the ability to handle various deviations. In view of the complex bending of the diaphragm, the single diaphragm coupling is not suitable for eccentricity.The double diaphragm coupling can bend in different directions at the same time to compensate for eccentricity.This characteristic is a bit like a bellows coupling, in fact the way the coupling transmits torque is similar.The diaphragm itself is very thin, so it is easy to bend when the relative displacement load is generated, so it can withstand up to XNUMX degrees of deviation, and at the same time produce a lower bearing load in the servo system.