JB type HG5-251-79 standard frameThe selection of JB type HG5-251-79 standard frame, the original...

JB type HG5-251-79 standard frameThe selection of JB type HG5-251-79 standard frame, the original... KC type sprocket couplingKC series sprocket coupling is used to connect...

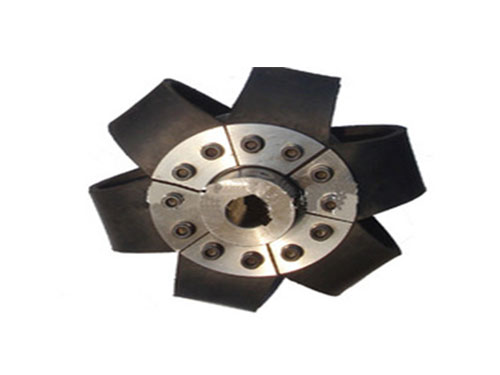

KC type sprocket couplingKC series sprocket coupling is used to connect... Three-jaw coupling for pumpThe three-jaw coupling for pumps uses a number of non...

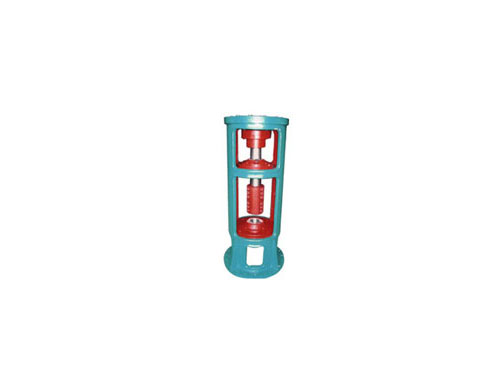

Three-jaw coupling for pumpThe three-jaw coupling for pumps uses a number of non... XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame...

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame... LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect...

LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect...Installation alignment and general application of serpentine spring coupling

Align the installation and control the correct deviation. Although the serpentine spring coupling allows large installation deviation, it should also be within the specified value during installation.

90. Alignment of the gap and angular deviation between the two couplings.When installing, measure the gap value between the two couplings every 0.38°, and the difference between the large value and the small value does not exceed XNUMXmm.

90. Correction of radial deviation.Place a ruler on the two-lobe coupling, measure it every 1°, and check with a feeler gauge. The radial deviation does not exceed 0.38mm.

Due to the existence of the deflection angle, the tooth surface contact spots move during operation, and the tooth surface load-bearing area and non-load-bearing area alternate with each other, so that the surface of the meshing tooth is in a mixed state of liquid lubrication, boundary lubrication and dry friction.When in the state of liquid lubrication, a good oil film is adhered to the tooth surface. The oil film separates the two tooth surfaces. The metal of the two tooth surfaces is not in direct contact, and the friction and wear are small. When in boundary lubrication, the tooth surface is only A very thin oil film layer is adhered to. Under the action of the tooth surface load, the oil film layer also bears the role of contact stress. At the same time, the contact point of the meshing tooth is constantly moving during operation, and friction is generated to increase the local temperature of the tooth surface. When the temperature rises, the viscosity of the lubricating oil will decrease, and the adhesion and anti-extrusion ability of the lubricating oil will decrease. The thin oil film layer of the tooth surface will be destroyed in a large amount under the action of contact stress, making the tooth surface metal Direct contact with metal becomes dry friction. At this time, the friction coefficient increases sharply, and the abrasion is aggravated, which eventually leads to adhesion.

The serpentine spring coupling has many excellent properties, such as: excellent shock absorption performance, long use of the equipment; and can withstand a wide range of variable loads, and start during work; and the transmission speed is good, and the working state is stable. , Operation; low noise during use, strong lubricity; simple structure, convenient assembly and disassembly.The equipment has few internal components, so it is light in weight and small in size for storage and carrying; even if there is a large error in the installation process, it will not affect the performance of the equipment; the operation is simple and the structure is compact.

The serpentine spring coupling is a structural metallic coupling that relies on the serpentine spring leaf to transmit torque.Its vibration damping performance is good, the service life is good, and the load variation is large; the transmission speed is good, the operation is good; the noise is low, the lubrication is good; the structure is simple, the assembly and disassembly are convenient, and the large installation deviation is allowed.Although the serpentine spring coupling has so many features and advantages, many brothers have changed it to an elastic pin coupling.As the user of the snake spring coupling, our company did not try to imitate it, but used it with good results.

XNUMX. Choose proper grease:

The lubricating point temperature is ≥150℃, which can resist centrifugal force, has separation stability, no impurities, and does not corrode carbon steel and nitrile rubber.

XNUMX. Fill enough grease:

Adequate lubrication is important for the work of the coupling. It is recommended to check once a year.Inject grease with a dry oil tool until excess grease overflows in the hole.

18. Control the working environment temperature of the coupling well, generally within 80~XNUMX℃.

The serpentine spring coupling is divided into two types: constant stiffness and variable stiffness, which mainly depend on the following two forms of spring contact teeth: the tooth shape is straight: the distance between the serpentine spring and the tooth contact point under normal load It does not change with the deformation of the serpentine spring, and the stiffness remains unchanged. The relative rotation angle of the two halves of the JSS double-flange serpentine spring coupling has a linear relationship with the transmitted torque, which is a constant stiffness serpentine spring coupling.

Serpentine spring couplings are commonly used in rock crushers, metallurgy, mining, and crane equipment, etc.; the equipment is suitable for the connection of medium and high power transmission shafts of two coaxial lines, and there is a standard compensation for the two shafts. Offset, vibration reduction, and buffer performance, the working environment temperature can be between minus 30 degrees Celsius and 150 degrees Celsius; when installing the device, you also need to pay attention to the control deviation, although it can allow a large error value, but in the installation The process should also be within the specified value; choosing the ideal grease can prolong the use time of the equipment.

The elasticity of the serpentine spring coupling is very good.The flexible effect of the spring can greatly reduce the vibration emitted during operation.The use time of the serpentine spring coupling is related to its production materials. For example, when selecting the material, a strong alloy steel product is used, and some processing will be performed on it to make the use effect, such as heating Disposal. This kind of treatment makes it flexible and flexible, because the spring on the coupling has undergone a rigorous sandblasting operation, which can compress the molecular structure of the surface of the serpentine spring coupling. , These operations make it use a long time.

The structure of the coupling is simple and easy to maintain. There are few parts for the serpentine spring coupling, so it is light in weight and small in size, which makes it very convenient to install and maintain. It does not require excessive maintenance. The more important maintenance is to apply grease to the corresponding shaft when the device is used for a long time. This will not only make the operation smoother, but also cause some noise.

Next:Nothing