Multi-section clamping diaphragm coupling1. Diaphragm elastic coupling 2. Gaoling...

Multi-section clamping diaphragm coupling1. Diaphragm elastic coupling 2. Gaoling... Elastic sleeveThe elastic sleeve uses a number of non-metal elastic...

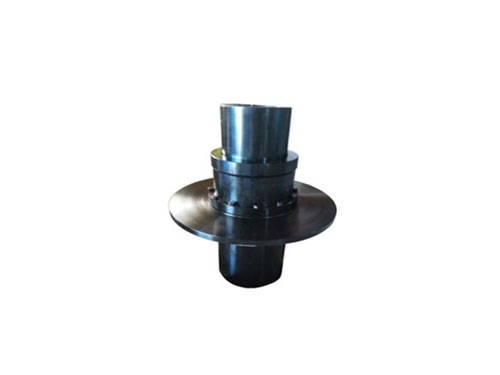

Elastic sleeveThe elastic sleeve uses a number of non-metal elastic... WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth...

WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth... Universal couplingThe universal coupling uses the characteristics of its mechanism...

Universal couplingThe universal coupling uses the characteristics of its mechanism... YLD type flange couplingYL type flange coupling can be made of gray cast iron or carbon...

YLD type flange couplingYL type flange coupling can be made of gray cast iron or carbon...Environmental protection performance and maintenance method of tire coupling for LLB metallurgical equipment

The tire-type coupling for LLB metallurgical equipment has a simple structure (composed of four pieces), convenient assembly and disassembly, no need to move the connected two shafts during disassembly, compact size, light weight, specific compensation capabilities, and low installation accuracy requirements , Work, longer life, lower cost and other advantages, tire couplings for LLB metallurgical equipment should work under the conditions of good lubrication and protective cover.

Environmental performance

The tire coupling for LLB metallurgical equipment has the hardness of steel, and the tire coupling for LLB metallurgical equipment has excellent environmental performance. LLB metallurgical equipment tire coupling super processing machine tool can achieve the required accuracy, but super processing due to the structure of the tire coupling, track, and spindle for LLB metallurgical equipment, this type of machine tool is not only expensive, but also has a small stroke , Low cutting efficiency, long installation time and other shortcomings, can meet the large-scale demand for larger size workpieces.No joints when rolling (ETFE lining thickness is 2-5mm), resistant to various concentrations of acids, alkalis, salts, strong hydrides, compounds and all other strong corrosive chemical media (the same as Teflon).

The tire coupling for LLB metallurgical equipment is an ideal product to solve the problems of high-temperature dilute sulfuric acid, hydrogen fluoride acid, hydrochloric acid and various acids. One of the processing characteristics of the layering problem of polyvinyl chloride lining equipment in its definition is within the allowable range Consider the size and dimensions of the part.If multiple parts are processed, the tolerance of 5.mU.M is retained, and if the two parts match, the tolerance of 2.mUM is retained, or a machine with a placement accuracy of 0.3 is used to process a machine with a smaller diameter.

Maintenance method

How to maintain the tire coupling for LLB metallurgical equipment?

LLB冶金设备用轮胎式联轴器上链轮齿数一般取12~22范围内偶数齿,若取较少的链轮齿数,则链轮上的作用力增加;若取较多的链轮数,则德国凌斯联轴器补偿能力降低,半联轴器上链轮的分度圆直径dp=(12~13.5)或dp=(2~3.2)d;罩壳外径DK=(1.15~1.2)dp;半联轴器外径D=(O.7~0.8)dp;半联轴器长度L=(1.9~2.8)d,大转矩时,取小的系数。

The advantages of tire coupling transmission for LLB metallurgical equipment are:

It can transmit movement and power when the two wheelbases are far away.It can work under low speed, heavy load and high temperature conditions and dusty conditions.The transmission ratio can be accurate, the transmission power is large, and the force acting on the shaft is small.transmission.

weakness is:

After the hinge of the chain is worn out, the pitch becomes larger and the joint is disjointed.Installation and maintenance requirements are high.The advantages of gear transmission are: the instantaneous transmission ratio is constant, the stability is high, and the transmission movement is accurate.The range of transmitted power and speed is large.The structure is compact, works, and can achieve a larger transmission ratio.Transmission and long service life.The disadvantages are: high manufacturing and installation requirements.