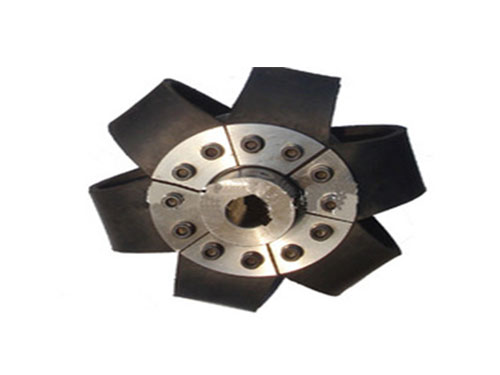

LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect...

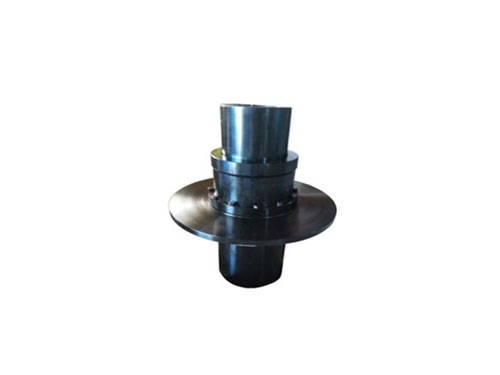

LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect... WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth...

WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth... GLF roller chain couplingGLF roller chain coupling is suitable for hydraulic machinery...

GLF roller chain couplingGLF roller chain coupling is suitable for hydraulic machinery... Tire coupling for LLB metallurgical equipmentTire coupling for LLB metallurgical equipment belongs to...

Tire coupling for LLB metallurgical equipmentTire coupling for LLB metallurgical equipment belongs to... NGCL type drum gear coupling with brake wheelNGCL type drum gear coupling with brake wheel...

NGCL type drum gear coupling with brake wheelNGCL type drum gear coupling with brake wheel...The editor of ever-power coupling teaches you how to extend the service life of serpentine spring couplings

The serpentine spring coupling is particularly suitable for low-speed and heavy-duty working conditions, such as metallurgy, mining, lifting and transportation industries, and also suitable for shaft transmission of various machinery such as petroleum, chemical industry, and general machinery.

An important way to extend service life

An important way to improve the service life of serpentine spring couplings.The tooth width coefficient affects the tooth root bending strength and tooth surface contact strength of the tooth. The larger the tooth width coefficient, the greater the strength of these two items. The tooth width coefficient affects the coincidence degree. When the tooth width coefficient is less than a specific value, its value The increase of, has a greater impact on the increase in the coincidence degree, and when it is greater than this specific value, the increase in the device value has a smaller impact on the increase in the coincidence degree. For the serpentine spring coupling with a circular bulge curve, the tooth width is still determined The bulge circle radius is also the parameter of the backlash. The larger the tooth width, the larger the bulge circle radius and the larger the backlash required. Therefore, the following bright spot requirements are required:

1) There is no edge contact phenomenon when the inclination angle between the shafts is large;

2) The smaller the gear tooth concentrated load, the better, and the curvature of the tooth surface is proportional to the circumference of the drum, so the drum radius is as large as possible.The curvature radius of the bulge curve is proportional to the single-sided thinning of the internal tooth, so the bulge circle radius should be as large as possible.The radius of curvature of the drum curve is proportional to the single-sided thinning of the internal tooth, that is, it is related to the meshing gap of the tooth. Insufficient thinning may cause interference, and excessive thinning will weaken the strength of the tooth, and the backlash will be large. .

Snake-shaped spring couplings are usually lubricated with lubricating oil. The tooth surface requires continuous lubrication. The lubricating oil should be drained smoothly, otherwise the temperature of the tooth surface will rise and accumulate moisture and dirt. The lubricating oil needs to be filtered by an oil filter. Less than 10 microns, some important serpentine spring couplings can also adopt the structure of the oil collecting groove hole, that is, the oil collecting groove is machined in the shaft hole of the external gear, and the oil hole communicating with the oil collecting groove is drilled at the bottom of the tooth groove of the external gear. The centrifugal force generated by the high-speed operation of the serpentine spring coupling sprays oil into the meshing part of the inner and outer teeth to make it fully lubricated.