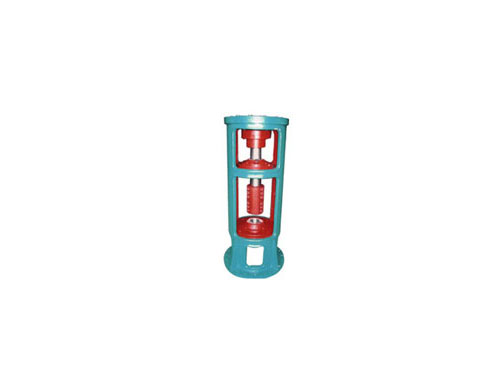

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame...

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame... Diaphragm coupling diaphragmDiaphragm couplings have a wide range of applications...

Diaphragm coupling diaphragmDiaphragm couplings have a wide range of applications... WF type non-telescopic flange universal couplingUniversal coupling is a kind of coupling,...

WF type non-telescopic flange universal couplingUniversal coupling is a kind of coupling,... SWP-E type cross shaft universal couplingSWP-E type cross shaft universal coupling is used to...

SWP-E type cross shaft universal couplingSWP-E type cross shaft universal coupling is used to... FCL type elastic sleeve pin couplingThe characteristics of FCL type elastic sleeve pin coupling...

FCL type elastic sleeve pin couplingThe characteristics of FCL type elastic sleeve pin coupling...The working principle and production requirements of plum coupling

The plum blossom coupling has many structural forms, a wide range of applications, and a variety of material choices.It is one of the most frequently selected models in the elastic coupling.Commonly used materials for plum couplings are gray iron, cast steel and aluminum alloy.The plum blossom coupling has simple structure, no lubrication, convenient maintenance, easy inspection, maintenance-free, and can run continuously for a long time.The polyurethane elastic element is resistant to wear and oil, has a large bearing capacity and a good service life.Work stably, with good vibration damping, buffering and electrical insulation properties.It has large axial, radial and angular compensation capabilities.The structure is simple, the radial dimension is small, the weight is light, and the moment of inertia is small, which is suitable for medium occasions.

The heat treatment of plum coupling is divided into preparation heat treatment (or pre-heat treatment) and final heat treatment (or post heat treatment). In modern industrial production, the heat treatment of the coupling has become an important technical regulation.This is due to the excellent mechanical functions of steel and certain alloys-high hardness, strength, elasticity and abrasion resistance, etc., in addition to the chemical components required during smelting, it must be obtained by heat treatment afterwards. Therefore, in order to achieve technical It is important that we need to heat-treat the coupling in the process of producing the coupling.

The working principle of plum coupling:

10. Before installation, check whether the two shafts of the prime mover and the working machine are concentric, and whether the surfaces of the two shafts have wrapping paper and bruises.Check whether there is debris in the inner holes of the two half couplings of the plum blossom coupling and whether there are bruises on the edges of the inner holes. If so, clean the shaft and half couplings, and handle the bruises with a fine file.Then check whether the inner hole diameter and length of the two half couplings are consistent with the diameter and shaft elongation of the prime mover and working machine.In general selection, it is better to make the length of the prime mover and the working machine end half-coupling less than its shaft elongation 30-XNUMXmm.

250. Alignment: Use a dial indicator to detect the runout of the flange end face and outer circle of the two halves of the coupling flange. When the outer circle of the flange is less than 005mm, the runout value should not be greater than 250mm; when the outer circle of the flange is greater than 008mm, The jitter value should not be greater than XNUMX.

XNUMX. Install the bolts: insert the bolts from the outside of the small hole of the flange, pass through the outside of the large hole of the other flange, put on the buffer sleeve, elastic washer, twist the nut, and tighten the nut with a wrench.If the installation is unsuitable or if it is removed and replaced without damaging the shaft and the half coupling, it is better to rotate freely after installation.

15. Practice has proved that if the installation, maintenance and operation are carried out according to the instructions and requirements, the number of daily starts of the plum blossom coupling is 5 times, and the service life of the coupling is more than XNUMX years. If the installation, maintenance, Operation, especially if the bolts are installed in the wrong direction to deform the coupling, or the prime mover and the working machine are offset too much, the coupling will be damaged in advance.

Fifth, in order to facilitate the installation, the two half couplings are placed in the 120150 insulation box or oil tank for preheating, so that the inner hole size increases and is easy to install.After installation, the shaft head should not protrude from the end face of the half coupling, it is better to be flush.Detect the distance between the two halves of the coupling: 34 points of readings measured along the two inner sides of the flange of the half coupling are averaged, and the sum of the measured dimensions of the extension and the two diaphragm sets is controlled by the error. Within the range of 0-04mm.

1. Instructions for operators: Before starting the equipment, check whether the nut of the torx coupling is loose or falling off. If so, tighten the nut with a wrench in time.The load line valve should be opened after starting the equipment with no load for XNUMX minute; the shutdown sequence is reversed. (Please paint the outside of the coupling with oil once a month).

The plum blossom coupling is a common type of coupling. Many people choose the plum blossom coupling when choosing a coupling. The plum blossom coupling has a simple structure, a small number of parts, a small radial dimension ratio, and no need for lubrication. , The elastic element has a relatively good pressure bearing capacity. Except for the double-flange plum-shaped elastic coupling, we need to move the half coupling axially when replacing the vulnerable plum-shaped elastic coupling, otherwise the replacement will fail. , The position will cause deviation. Although the plum blossom coupling is a small object, it has a big function.

Production technical requirements for plum coupling:

XNUMX. The coupling should be cleaned before packaging, and the coupling surface should be coated with anti-rust agent, and the non-coupling surface should be coated with paint or other anti-rust treatment.

XNUMX. Couplings need to be trial-assembled before leaving the factory. The half-couplings and the elastic parts should be installed in no less than two positions relative to each other, which should be convenient for assembly and disassembly.

XNUMX. The coupling used under working conditions should undergo a balance test with the main shaft system.

XNUMX. Large operating compensation refers to the two-axis phase offset formed by comprehensive factors such as manufacturing errors, installation errors, and changes in working load caused by vibration, impact, and temperature changes in the working state.

XNUMX. The shape of the elastic parts should be smooth and flat. The working surface should not have pitting, and there should be no defects such as impurities, bubbles, cracks, etc. inside.

3852. The shaft hole tolerance of the half coupling is in accordance with the provisions of GB/T17-1.6, and the surface roughness Ra value of the shaft hole is not less than XNUMXum.

45. The surface of half coupling, flange coupling, flange half coupling, brake wheel, brake wheel half coupling is not allowed to have cracks, shrinkage holes, air bubbles, slag inclusion and other defects that affect strength. The surface of the brake wheel should be quenched, the hardness is 55~3HRC, and the hardened layer is greater than XNUMXmm.

Next:Nothing