XL connection middle sleeve type star elastic couplingXL connection middle sleeve type star elastic coupling...

XL connection middle sleeve type star elastic couplingXL connection middle sleeve type star elastic coupling... ML plum-shaped elastic couplingML plum-shaped elastic coupling and other coupling...

ML plum-shaped elastic couplingML plum-shaped elastic coupling and other coupling... JS type housing radial mounting type couplingSelection of JS type housing radial mounting type coupling...

JS type housing radial mounting type couplingSelection of JS type housing radial mounting type coupling... LXD type single flange star elastic couplingLXD type single flange star elastic coupling is...

LXD type single flange star elastic couplingLXD type single flange star elastic coupling is... HL type elastic pin couplingThe elastic pin coupling (GB5014-85) is suitable for...

HL type elastic pin couplingThe elastic pin coupling (GB5014-85) is suitable for...How to solve the obvious vibration in the use of the serpentine spring coupling?

The serpentine spring coupling embeds more than two half and thirty-six percent in the axial direction of the serpentine spring sheet.The serpentine spring sheet with trapezoidal section is made of high quality spring steel, which has undergone strict heat treatment and is specially processed. It has good mechanical properties, so that the service life of the coupling is much longer than that of non-metallic elastic element couplings such as elastic sleeve columns. Pins, nylon rod pin couplings have greatly increased.Because the spring leaf and the tooth arc surface are in point contact, the coupling can obtain greater flexibility.It can be installed to work normally under conditions of radial, angular and axial deviations at the same time.Regarding the inspection of the snake spring coupling: When the rubber ring and the leather pad are damaged, they need to be replaced as soon as possible. If the pin or the hole is destroyed and the vibration occurs, it is necessary to rotate the half body at an angle Drill the hole once and replace the standard new pin. It is not possible to expand the original hole with a new pin.

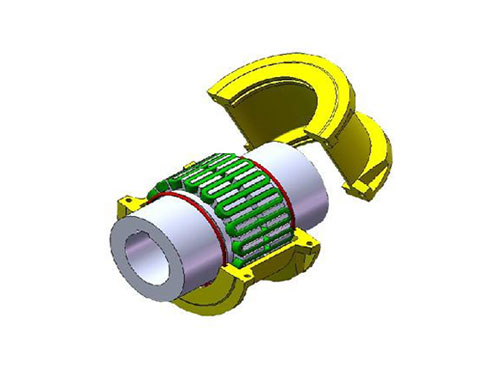

So, if we want to understand the serpentine spring coupling, how to analyze the serpentine spring coupling tooth profile as straight or curved?The serpentine spring coupling uses serpentine springs divided into one or several groups and is embedded in the teeth on the flange of the two-part coupling to realize the connection of the two halves of the coupling. In order to prevent the serpentine spring It is thrown out under the action of centrifugal force and to avoid dry friction between the serpentine spring and the tooth contact. It needs to be covered with a closed shell and filled with lubricating oil or grease.The serpentine spring coupling is divided into two types: transverse stiffness and variable stiffness, which are mainly determined by the following two shapes of the tooth contact with the spring: shaft transmission of various other machinery and equipment, usually with a motor connected to the shaft, and a motor and a reduction box It can be applied wherever the shaft is connected or the shaft is connected.Mainly used in rock crusher, crank reciprocating motion, reducer, metallurgy, mining, hoisting machinery, etc.

XNUMX. The serpentine spring coupling can withstand large changes in load

1. The tooth surfaces of the two half couplings in contact with the reeds are curved. When the transmission torque increases, the springs will deform along the curved surfaces of the teeth, so that the force points of the two half couplings on the reeds are close .The contact point between the reed and the tooth surface, that is, the change of torque, changes with the size of the transmitted torque, and its transmission characteristics are variable stiffness.

2. The buffering effect produced by the transmission force when the reed deforms along the tooth arc, especially when the machine is started or impact load, to a corresponding degree to protect the stability of the supporting parts.

3. The transmission speed of the coupling has been determined to be above, and its short-term overload capacity is twice the rated torque, and the operation is stable.

4. The aluminum alloy casing protects the spring from being thrown out during operation, and the casing is filled with butter, which not only makes the lubrication good, but also makes the noise of the reed meshing be absorbed and removed by the butter damping.

XNUMX. How to solve the obvious vibration in the use of the serpentine spring coupling?

(1) Whether there is an obvious passing frequency of the blades, and the field test has confirmed that the fan vibration has no relationship with the opening of the baffle, indicating that the flow part of the fan is normal.

(2) According to the field measurement data, the vibration of the non-drive end of the fan (impeller side) is less than the vibration of the drive end. The vibration of the two fans is not caused by the unbalanced mass of the serpentine spring coupling of the impeller itself or the unbalanced mass of the fan rotor after installation caused.

(3) Bearings and vibrations in all directions are dominated by power frequency, with obvious double frequency components.Whether there is an obvious bearing failure frequency, it indicates that the bearings are not faulty and the installation and lubrication are good.

Through the above analysis, the causes of failure such as unbalanced mass of the fan impeller, unbalanced fan rotor, bearing damage and poor installation lubrication, and damage to the flow part of the fan are eliminated.The vibration of the bearing at the drive end of the fan is greater than that of the non-drive end. The bearing vibration at the drive end of the fan is close to the motor drive end bearing in size and opposite in phase. The horizontal, vertical and axial vibrations of each bearing are relatively large, and the double-frequency component in the frequency spectrum is more obvious Other phenomena indicate that the two fans may have the problem of misalignment between the fan rotor and the motor rotor.Fault confirmation and handling process The fault confirmation is determined after discussion, and the alignment of the fan rotor and the motor rotor is rechecked.First, measure the beating of the fan and motor side journal without removing the serpentine spring coupling cover, then untie the serpentine spring coupling cover to measure the alignment of the two rotors, and then remove the serpentine spring Measure the alignment of the two rotors.