Rigid couplingThe characteristics of rigid coupling: rigid coupling...

Rigid couplingThe characteristics of rigid coupling: rigid coupling... GR-shaped coupling elastic bodyGR-shaped coupling elastic body and star-shaped elastic...

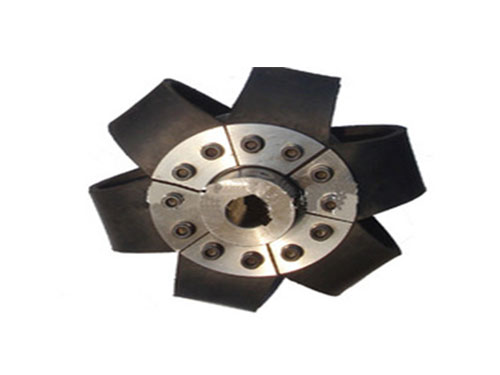

GR-shaped coupling elastic bodyGR-shaped coupling elastic body and star-shaped elastic... LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect...

LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect... JMJ diaphragm couplingJMJ diaphragm coupling torque control range...

JMJ diaphragm couplingJMJ diaphragm coupling torque control range... JQ type clamp couplingThe characteristics of the JQ type clamp coupling and the clamp...

JQ type clamp couplingThe characteristics of the JQ type clamp coupling and the clamp...Reasons for choosing diaphragm coupling

In many power plants, couplings are used in their electrical equipment, and because of long-term use and wear, they are more frequent. Compared with gear couplings, the use of diaphragm couplings not only reduces operating costs, but also Also reduces noise.

So why use a diaphragm coupling? What are its advantages?

1. Compared with the gear coupling, the diaphragm coupling has no relative sliding, eliminating the trouble of lubrication and sealing. The low maintenance cost and convenient manufacturing process make it widely used in various industries.

2. For the compensation of the misalignment of the two axes of the motor and the equipment, the angular displacement of the gear coupling can be doubled; the large flexibility and small reaction force during radial displacement allow axial, radial and angular displacement .

3. Higher transmission efficiency, especially suitable for medium, high speed and high power transmission scenarios.Simple and light structure, small size, convenient for assembly and disassembly.For example, the diaphragm coupling of the intermediate shaft type structure can be assembled and disassembled without moving the machine.

4. Large-scale damping effect, low noise and no wear.

5. It can adapt to high temperature and harsh working environment, and can resist shock and vibration during equipment operation.

6. It can accurately transmit the speed without slip, suitable for the mechanical transmission of.