YLD type flange couplingYL type flange coupling can be made of gray cast iron or carbon...

YLD type flange couplingYL type flange coupling can be made of gray cast iron or carbon... JSP type coupling with brake discJSP type couplings with brake discs generally should...

JSP type coupling with brake discJSP type couplings with brake discs generally should... WF type non-telescopic flange universal couplingUniversal coupling is a kind of coupling,...

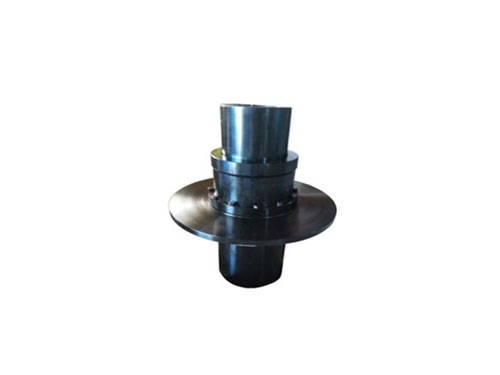

WF type non-telescopic flange universal couplingUniversal coupling is a kind of coupling,... WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth...

WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth... Tire coupling for LLB metallurgical equipmentTire coupling for LLB metallurgical equipment belongs to...

Tire coupling for LLB metallurgical equipmentTire coupling for LLB metallurgical equipment belongs to...Selection Principles of Pump Couplings and Working Conditions of Couplings

Regarding the question of how to choose pump couplings, generally we recommend that users choose pump couplings to follow three principles:

XNUMX. The structure of the three-jaw coupling for the pump is to place the opposite wheel pad of the plum blossom hexagonal pump between the half couplings with three claws, which is roughly similar to the office principle of the plum blossom coupling. The wheel pad implements a pressure-increasing variant to transmit torque.This kind of coupling is suitable for small-scale pumps.The claw-type elastic coupling is also called the elastic block coupling. It is characterized by small size, light weight, simple structure, and convenient installation. It is often used in small power and unimportant occasions.

XNUMX. The elastic pin coupling is to fill the nylon rod into the flange holes of the two halves of the coupling, and then use the baffle to fix the nylon rod on the two halves of the coupling. Hand torque.This kind of coupling is relatively suitable for large-scale use.The pin is connected to the flanges of the two halves of the coupling. One end of the pin is fixedly fitted with the conical surface and the taper pin hole of the nut and the flange of the half coupling. The other end is equipped with an elastic sleeve, which is installed in In the pin hole of the other half of the coupling flange.The elastic sleeve is made of rubber.

XNUMX. The elastic sleeve pin coupling is to put a rubber ring on the pin in a group, and then use a screw cap to fix it on the flange holes of the two halves of the coupling. The rubber ring has elasticity and has the ability to compensate for axis displacement. experience.This kind of coupling is suitable for medium-sized pumps.It is a non-metal elastic element coupling with simple structure, no lubrication, convenient installation, easy replacement, and does not require high centering accuracy. It is often used in pumps with lower power.There are many domestic manufacturers.

Commonly used coupling types for pumps are: claw-type elastic coupling, elastic pin coupling and diaphragm coupling.Accurate centering requirements for installation, shock mitigation, changing the natural vibration frequency of the shafting, and avoiding hazardous vibrations, etc.In addition, the elastic pin coupling is connected with the flange of the two halves of the coupling by a pin, and one end of the pin is conical surface and a nut with a tapered pin hole on the flange of the half coupling. Form a fixed fit, the other end has an elastic sleeve, which is installed in the pin hole of the other half of the coupling flange. The elastic sleeve is made of rubber. It is characterized by simple structure, convenient installation, easy replacement, small size, and light weight. The transmission torque is large.

Under normal circumstances, the existing standard coupling can basically meet the needs of different working conditions.

1.5. Diaphragm characteristics: The characteristic of the coupling diaphragm is a bit like a bellows coupling. In fact, the way the coupling transmits torque is similar.The diaphragm itself is very thin, so it is easy to bend when the relative displacement load is generated, so it can withstand up to XNUMX degrees of deviation, while generating a lower bearing load in the servo system.Diaphragm couplings are often used in servo systems. Diaphragms have good torque rigidity, but are slightly inferior to bellows couplings.On the other hand, the diaphragm coupling is particularly delicate and can be easily damaged if it is misused or improperly installed during use.Therefore, it is particularly necessary to determine that the deviation is within the tolerance range of the normal operation of the coupling.Choosing the right coupling is a key step to make good use of the coupling. In the design stage, you have to consider what type of coupling to choose.

9147. Diaphragm advantages: Compared with gear couplings, the diaphragm of the coupling has no relative sliding, no lubrication, sealing, no noise, basically no maintenance, easy to manufacture, and can partially replace the gear coupling.Diaphragm couplings are commonly used in industrially developed countries around the world. Machinery industry standards have been formulated in our country, and have recently been revised into new industry standards: JB/T19-19022 (instead of ZB/TJ90-XNUMX) couplings The relationship between the torques

XNUMX. Application range: widely used in shaft transmission of various mechanical devices, such as water pumps (especially high-power, chemical pumps), fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining Machinery, metallurgical machinery, naval high-speed power transmission systems, steam turbines, piston-type power mechanical transmission systems, tracked vehicles, and high-speed, high-power mechanical transmission systems of generator sets are commonly used in high-speed transmission shaft systems after dynamic balance.

XNUMX. Introduction: The diaphragm coupling compensates for the relative displacement of the two shafts connected by the elastic deformation of the diaphragm. It is a high-performance flexible coupling with strong metal components. It does not require lubrication and has a compact structure. Long life, no rotation gap, not affected by temperature and oil pollution, acid and alkali resistance, suitable for high temperature, high speed, and corrosive medium shafting environment.

XNUMX. No structure: The coupling diaphragm is composed of at least one diaphragm and two shaft sleeves.The diaphragm is fastened to the shaft sleeve with a pin and generally does not loosen or cause backlash between the diaphragm and the shaft sleeve.Some manufacturers provide two diaphragms, and some provide three diaphragms, with one or two rigid elements in the middle, and the two sides are connected to the shaft sleeve.The difference between the single diaphragm coupling and the double diaphragm coupling is the ability to handle various deviations. In view of the complex bending of the diaphragm, the single diaphragm coupling is not suitable for eccentricity.The double diaphragm coupling can bend in different directions at the same time to compensate for eccentricity.