TB type HG5-251-69 standard rackThe standard frame of TB type HG5-251-69 is "glass-lined...

TB type HG5-251-69 standard rackThe standard frame of TB type HG5-251-69 is "glass-lined... Small size universal couplingCommon types of universal couplings are: universal...

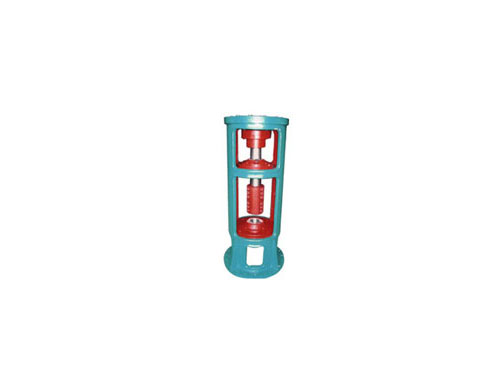

Small size universal couplingCommon types of universal couplings are: universal... XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame...

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame... JSZ type brake wheel couplingThe structure of JSZ type brake wheel coupling...

JSZ type brake wheel couplingThe structure of JSZ type brake wheel coupling... Multi-section clamping diaphragm coupling1. Diaphragm elastic coupling 2. Gaoling...

Multi-section clamping diaphragm coupling1. Diaphragm elastic coupling 2. Gaoling...How about the operation of the elastic sleeve pin coupling for the pump? The ever-power coupling will chat with you.

The elastic sleeve pin coupling for pump is used to improve the operation of the shaft system, adjust the torsional vibration characteristics of the transmission device shaft system, compensate for the displacement of the main and driven motor axes caused by vibration and impact, and continuously transmit torque and A moving torsion elastic compound rubber coupling device.It has high elasticity and good damping, can compensate the axial displacement, radial displacement and angular displacement of the connecting mechanism, and can better solve the torsional vibration problem of the shaft system, which can buffer vibration and reduce noise And so on.It is widely used in diesel engine power plants of ships, heavy-duty vehicles and other industries and transmission shafts with large interference torque to achieve the purpose of vibration reduction and noise reduction, and to protect the main and driven motives and improve the operability of the entire transmission. effect.

The elastic element is the key component of the elastic sleeve pin coupling for the pump. It can absorb energy to attenuate vibration and alleviate impact; at the same time, its high elasticity and low stiffness physical properties can help realize displacement compensation and greatly adjust the natural frequency of the transmission device. , To achieve the purpose of avoiding resonance and reducing structural noise.Therefore, the development of elastic elements largely determines the development of elastic sleeve pin couplings for pumps.

At present, the elastic sleeve pin couplings for pumps are classified according to the elastic elements. There are two main categories: elastic sleeve pin couplings for pumps with metal elastic elements and elastic sleeve pin couplings for pumps with non-metal elastic elements.

The common characteristics of metal elastic components are fatigue, large carrying capacity, good load-bearing capacity, long service life, stable performance, and easy control of dynamic performance, but the manufacturing requirements are strict and the cost is high.

Non-metallic elastic element elastic pin couplings mainly include elastic sleeve pin couplings, elastic sleeve pin couplings for quincunx pumps, tire couplings, etc. The common features are small quality and easy molding. The internal friction is large, the damping performance is good, the storage capacity per unit volume is much, no mechanical friction, no lubrication is needed, but the strength is low, and the high and low temperature resistance is poor.

The elastic element is a key component of the elastic sleeve pin coupling for pumps. It can produce significant elastic deformation when under load. On the one hand, it plays a role in compensating the relative displacement between the two connected shafts, and secondly, it can be stored elastically. Deformation achieves a buffering effect. Third, the natural frequency of the system can be adjusted by changing the structural rigidity of the coupling to reduce vibration and avoid resonance.Therefore, to design an elastic sleeve pin coupling for pumps with excellent transmission performance, the key is to design the elastic elements in it.