NGCL type drum gear coupling with brake wheelNGCL type drum gear coupling with brake wheel...

NGCL type drum gear coupling with brake wheelNGCL type drum gear coupling with brake wheel... Diaphragm coupling diaphragmDiaphragm couplings have a wide range of applications...

Diaphragm coupling diaphragmDiaphragm couplings have a wide range of applications... FZ type double fulcrum square bottom plate rackFZ type double fulcrum square bottom plate rack series is suitable for...

FZ type double fulcrum square bottom plate rackFZ type double fulcrum square bottom plate rack series is suitable for... JSB type axial mounting couplingThe general material of J-type axial installation coupling...

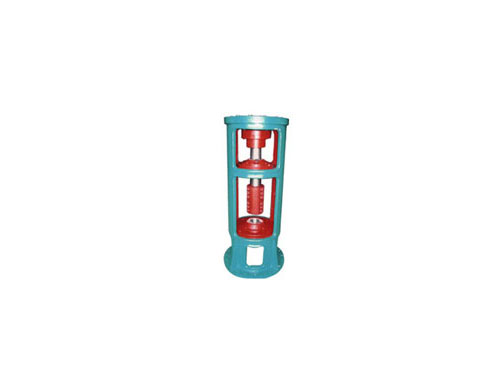

JSB type axial mounting couplingThe general material of J-type axial installation coupling... XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame...

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame...Diaphragm couplings are often used in servo systems

The diaphragm coupling is mainly made of cast special steel.There are many kinds of alloy cast steels refined to meet special needs, usually containing one or more high amount of alloying elements to obtain certain special properties.For example, high manganese steel with XNUMX% manganese is resistant to impact and wear, and is mostly used for parts of mining machinery and construction machinery; various stainless steels with chromium or chromium-nickel as the main alloying elements are used in corrosion or XNUMX Parts that work under high temperature conditions of about ten degrees Celsius, such as chemical valve bodies, pumps, containers, or steam turbine shells for large-capacity power stations.

The balance level of any coupling component is determined according to the root-sum-square value of the larger possible value of the eccentricity of the center of gravity between the main axis of inertia of the coupling and the axis of rotation.Its imbalance is expressed in microns.The potential unbalance factors of the coupling components have been introduced above, and the various steps of determining the balance level of various types of coupling components and calculating the balance are shown in the calculation examples.Inspection of the snake spring coupling: When the rubber ring and the leather pad are damaged, they need to be replaced as soon as possible. If the pin or hole is destroyed and vibration occurs, it is necessary to drill an angle of the half body rotation once. Hole, replace the standard new pin, you can not expand the original hole with a new pin.

The coupling chooser should choose the appropriate balance level of the coupling, the rigidity of the bearing, bearing seat, and base: For rotating parts, the mechanical transmission system has a flexible base or bracket, which is more sensitive to the unbalanced state of the coupling.

Whether the unbalance of the coupling can meet the needs of any type of rotating system depends on the performance of various special connected machines, and is better determined by the manufacturer that produces the connected machines.

Diaphragm couplings are often used in servo systems

1. Diaphragm couplings are often used in servo systems. Diaphragms have good torque rigidity, but are slightly inferior to bellows couplings.

2. The characteristic of diaphragm coupling is a bit like a bellows coupling. In fact, the way the coupling transmits torque is similar.The diaphragm itself is very thin, so it is easy to bend when the relative displacement load is generated, so it can withstand up to 1.5 degrees of deviation, while generating a lower bearing load in the servo system.

3. The diaphragm coupling is composed of at least one diaphragm and two shaft sleeves.The diaphragm is fastened to the shaft sleeve with a pin and generally does not loosen or cause backlash between the diaphragm and the shaft sleeve.Some manufacturers provide two diaphragms, and some provide three diaphragms, with one or two rigid elements in the middle, and the two sides are connected to the shaft sleeve.

4. On the other hand, the diaphragm coupling is particularly delicate, and it is easy to be damaged if it is misused or not installed correctly during use.Therefore, it is determined that the deviation is within the tolerance range of the normal operation of the coupling.

The initially selected coupling dimensions of the bearing coupling, namely the diameter d of the shaft hole and the length L of the shaft hole, should meet the requirements of the shaft diameter of the driving and driven ends. Otherwise, the specifications of the coupling should be adjusted according to the shaft diameter d.It is a common phenomenon that the shaft diameters of the driving and driven ends are different. When the torque and speed are the same, and the shaft diameters of the driving and driven ends are different, the coupling model should be selected according to the large shaft diameter.In the newly designed transmission system, seven shaft hole types that meet the requirements should be selected. J1 shaft hole type is recommended to improve versatility and interchangeability. The shaft hole length is in accordance with the i-bearing coupling product standard.

The serpentine spring coupling is divided into two types of transverse stiffness and variable stiffness, which mainly depend on the following two shapes of the teeth in contact with the spring: shaft transmission of various other machinery and equipment, usually with a motor connected to a shaft, a motor and a reduction box It can be applied wherever the shaft is connected or the shaft is connected.Mainly used in rock crusher, crank reciprocating motion, reducer, metallurgy, mining, hoisting machinery, etc.

The tooth surfaces of the two half couplings in contact with the reeds are curved. When the transmission torque increases, the springs will deform along the curved surfaces of the teeth, so that the force points of the two half couplings on the reeds are close.The contact point between the reed and the tooth surface, that is, the change of torque, changes with the size of the transmitted torque, and its transmission characteristics are variable stiffness.Therefore, it has a larger load variation than general elastic couplings.The buffering effect produced by the transmission force when the reed deforms along the tooth arc, especially when the machine is started or when the impact load, protects the stability of the supporting parts to a corresponding degree.

The aluminum alloy casing protects the spring from being thrown out during operation, and the casing is filled with butter, which not only makes the lubrication good, but also makes the noise of the reed meshing be absorbed and removed by the butter damping.

The transmission speed of the coupling, its short-term overload capacity is twice the rated torque, and the operation is stable.

The whole machine has few parts, small size and light weight. The spring leaf designed as a trapezoidal cross-section and the trapezoidal tooth groove are particularly convenient and close, so that the assembly, disassembly and maintenance are simpler than ordinary couplings.