Product Description

Hydraulic Coupling StainlessSteel Aluminum Camlock Couplings Metric Flexible Yoxm Hydrodynamic Hydrokinetic for Automobile Transmission Fluid Hydraulic Coupling

Application of Hydraulic Coupling

Hydraulic coupling is a device that uses a fluid to transmit power from 1 shaft to another. It is also known as a fluid coupling or hydrodynamic coupling. Hydraulic couplings are used in a wide variety of applications, including:

- Machine tools: Hydraulic couplings are used in machine tools such as lathes, milling machines, and drills to transmit power from the motor to the machine.

- Conveyors: Hydraulic couplings are used in conveyors to transmit power from the motor to the conveyor belt.

- Pumps: Hydraulic couplings are used in pumps to transmit power from the motor to the pump impeller.

- Fans: Hydraulic couplings are used in fans to transmit power from the motor to the fan blades.

- Generators: Hydraulic couplings are used in generators to transmit power from the turbine to the generator rotor.

- Wind turbines: Hydraulic couplings are used in wind turbines to transmit power from the turbine to the generator.

Here are some of the advantages of using hydraulic couplings:

- Smooth start-up: Hydraulic couplings allow for smooth start-up of the driven machine, which can help to prevent damage to the machine.

- Variable speed operation: Hydraulic couplings can be used to provide variable speed operation of the driven machine, which can be useful in applications where the speed of the machine needs to be adjusted.

- Shock absorption: Hydraulic couplings can absorb shock loads, which can help to protect the driven machine from damage.

- Durability: Hydraulic couplings are durable and can withstand a wide range of operating conditions.

Here are some of the disadvantages of using hydraulic couplings:

- Loss of efficiency: Hydraulic couplings can lose some of the power that is transmitted through them.

- Cost: Hydraulic couplings can be more expensive than other types of couplings.

- Maintenance: Hydraulic couplings require periodic maintenance, such as checking the fluid level and replacing the fluid as needed.

Overall, hydraulic couplings are a versatile and reliable type of coupling that can be used in a wide variety of applications. They offer a number of advantages over other types of couplings, but they also have some disadvantages. The best type of coupling for a particular application will depend on the specific requirements of that application.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Fluid Couplings in Conjunction with Electric Motors

Yes, fluid couplings can be used in conjunction with electric motors to provide a reliable and efficient power transmission solution. When coupled with an electric motor, the fluid coupling serves as a mechanical torque converter, enabling smooth start-ups and gradual acceleration of the driven load.

The combination of a fluid coupling and an electric motor offers several advantages:

- Soft Start: When the electric motor is switched on, it accelerates gradually as the fluid coupling allows the torque to build up slowly. This soft start feature reduces mechanical stress on the driven equipment and minimizes the impact on the electrical supply, preventing voltage drops and surges.

- Overload Protection: Fluid couplings can automatically disengage when the load exceeds a certain threshold, providing overload protection to both the motor and the driven equipment. This feature helps prevent damage to the system during abrupt load changes or stall conditions.

- Vibration Damping: The fluid in the coupling acts as a damping medium, reducing vibration and shock loads during start-ups and sudden load changes. This contributes to smoother operation and extends the lifespan of the connected machinery.

- Energy Efficiency: By facilitating soft start and controlling torque transmission, fluid couplings improve the energy efficiency of the system. They reduce the inrush current during start-up, which can lead to significant energy savings in the long run.

- Variable Speed Control: In some configurations, fluid couplings can be combined with Variable Frequency Drives (VFDs) to provide variable speed control. The VFD regulates the speed of the electric motor, while the fluid coupling ensures smooth and controlled power transmission to the driven equipment.

Overall, the combination of a fluid coupling with an electric motor is a versatile solution that finds applications in various industries. It allows for reliable and controlled power transmission, protecting both the motor and the driven equipment while improving system efficiency.

Fluid Couplings for Soft-Start Applications in Conveyor Systems

Yes, fluid couplings are well-suited for soft-start applications in conveyor systems. Soft-starting is the gradual acceleration of the conveyor belt to reduce sudden mechanical stress and current spikes during startup. Fluid couplings provide a smooth and controlled method of power transmission, making them ideal for achieving soft-start capabilities in conveyor systems.

When a conveyor system equipped with a fluid coupling starts, the fluid inside the coupling initially acts as a viscous medium, allowing the input and output shafts to rotate at different speeds. As the fluid coupling fills with fluid, it gradually transmits torque and smoothly accelerates the conveyor belt.

One of the significant advantages of using fluid couplings for soft-start applications is that they provide adjustable startup times. By controlling the amount of fluid inside the coupling, the startup acceleration rate can be precisely tuned to match the specific requirements of the conveyor system.

The soft-start feature offered by fluid couplings helps in several ways:

- Mechanical Stress Reduction: The gradual acceleration minimizes mechanical stress on the conveyor belt, pulleys, and other components, leading to extended equipment life and reduced maintenance costs.

- Energy Savings: Soft-starting prevents sudden current spikes and reduces the power demand during startup, resulting in energy savings and improved efficiency.

- Improved Conveyor Belt Life: By avoiding abrupt starts, the wear and tear on the conveyor belt are reduced, leading to longer belt life and decreased downtime.

- Enhanced Conveyor Control: Soft-start capabilities enable better control over the conveyor system, allowing operators to optimize the material flow and prevent product spillage or jamming.

Fluid couplings offer reliable and cost-effective soft-start solutions for conveyor systems across various industries, including mining, manufacturing, and material handling. They are particularly beneficial when dealing with heavy loads or long conveyor belts, where the avoidance of sudden shock loads is critical.

In summary, fluid couplings are a popular choice for soft-start applications in conveyor systems due to their smooth and controlled power transmission, adjustable startup times, and the ability to reduce mechanical stress and energy consumption during startup.

Fluid Couplings and Variable Speed Control

Fluid couplings are well-suited for certain applications that require variable speed control. While fluid couplings are primarily designed for smooth power transmission and torque multiplication, they can be used in combination with other devices to achieve variable speed control.

The primary method of achieving variable speed control with a fluid coupling is by using a hydraulic coupling or a hydraulic torque converter. A hydraulic coupling is essentially a fluid coupling with an additional chamber that allows for controlled fluid flow. By adjusting the fluid flow rate, the output speed can be varied, thus providing variable speed control.

Hydraulic torque converters are similar to fluid couplings but have an additional component called a stator. The stator redirects the fluid flow in a way that enhances torque multiplication at low speeds and improves efficiency at high speeds. By altering the stator’s position, the output speed can be varied, enabling variable speed control.

Variable speed control with fluid couplings is often used in applications such as industrial machinery, mining equipment, and certain types of vehicles. It allows for smooth and efficient speed adjustments without the need for mechanical gear changes, providing flexibility in various operating conditions.

However, it’s important to note that while fluid couplings can offer some degree of variable speed control, they are not as versatile as other speed control mechanisms like variable frequency drives (VFDs) or electronic controllers. Therefore, the selection of the appropriate speed control method depends on the specific requirements and characteristics of the application.

editor by CX 2024-05-08

China high quality Hydraulic Coupling Stainlesssteel Aluminum Camlock Couplings Metric Flexible Yoxm Hydrodynamic Hydrokinetic for Automobile Transmission Fluid Hydraulic Coupling

Product Description

Hydraulic Coupling StainlessSteel Aluminum Camlock Couplings Metric Flexible Yoxm Hydrodynamic Hydrokinetic for Automobile Transmission Fluid Hydraulic Coupling

Application of Hydraulic Coupling

Hydraulic coupling is a device that uses a fluid to transmit power from 1 shaft to another. It is also known as a fluid coupling or hydrodynamic coupling. Hydraulic couplings are used in a wide variety of applications, including:

- Machine tools: Hydraulic couplings are used in machine tools such as lathes, milling machines, and drills to transmit power from the motor to the machine.

- Conveyors: Hydraulic couplings are used in conveyors to transmit power from the motor to the conveyor belt.

- Pumps: Hydraulic couplings are used in pumps to transmit power from the motor to the pump impeller.

- Fans: Hydraulic couplings are used in fans to transmit power from the motor to the fan blades.

- Generators: Hydraulic couplings are used in generators to transmit power from the turbine to the generator rotor.

- Wind turbines: Hydraulic couplings are used in wind turbines to transmit power from the turbine to the generator.

Here are some of the advantages of using hydraulic couplings:

- Smooth start-up: Hydraulic couplings allow for smooth start-up of the driven machine, which can help to prevent damage to the machine.

- Variable speed operation: Hydraulic couplings can be used to provide variable speed operation of the driven machine, which can be useful in applications where the speed of the machine needs to be adjusted.

- Shock absorption: Hydraulic couplings can absorb shock loads, which can help to protect the driven machine from damage.

- Durability: Hydraulic couplings are durable and can withstand a wide range of operating conditions.

Here are some of the disadvantages of using hydraulic couplings:

- Loss of efficiency: Hydraulic couplings can lose some of the power that is transmitted through them.

- Cost: Hydraulic couplings can be more expensive than other types of couplings.

- Maintenance: Hydraulic couplings require periodic maintenance, such as checking the fluid level and replacing the fluid as needed.

Overall, hydraulic couplings are a versatile and reliable type of coupling that can be used in a wide variety of applications. They offer a number of advantages over other types of couplings, but they also have some disadvantages. The best type of coupling for a particular application will depend on the specific requirements of that application.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Fluid Couplings in Conjunction with Electric Motors

Yes, fluid couplings can be used in conjunction with electric motors to provide a reliable and efficient power transmission solution. When coupled with an electric motor, the fluid coupling serves as a mechanical torque converter, enabling smooth start-ups and gradual acceleration of the driven load.

The combination of a fluid coupling and an electric motor offers several advantages:

- Soft Start: When the electric motor is switched on, it accelerates gradually as the fluid coupling allows the torque to build up slowly. This soft start feature reduces mechanical stress on the driven equipment and minimizes the impact on the electrical supply, preventing voltage drops and surges.

- Overload Protection: Fluid couplings can automatically disengage when the load exceeds a certain threshold, providing overload protection to both the motor and the driven equipment. This feature helps prevent damage to the system during abrupt load changes or stall conditions.

- Vibration Damping: The fluid in the coupling acts as a damping medium, reducing vibration and shock loads during start-ups and sudden load changes. This contributes to smoother operation and extends the lifespan of the connected machinery.

- Energy Efficiency: By facilitating soft start and controlling torque transmission, fluid couplings improve the energy efficiency of the system. They reduce the inrush current during start-up, which can lead to significant energy savings in the long run.

- Variable Speed Control: In some configurations, fluid couplings can be combined with Variable Frequency Drives (VFDs) to provide variable speed control. The VFD regulates the speed of the electric motor, while the fluid coupling ensures smooth and controlled power transmission to the driven equipment.

Overall, the combination of a fluid coupling with an electric motor is a versatile solution that finds applications in various industries. It allows for reliable and controlled power transmission, protecting both the motor and the driven equipment while improving system efficiency.

Temperature Limitations of Fluid Couplings

Fluid couplings, like any mechanical component, have temperature limitations that must be considered to ensure their proper and safe operation. The temperature limitations of fluid couplings are influenced by the type of fluid used inside the coupling, the ambient operating conditions, and the specific design and construction of the coupling.

The primary concern regarding temperature is the heat generated during the operation of the fluid coupling. The heat is a result of friction and fluid shear within the coupling as it transmits power between the input and output shafts. Excessive heat generation can lead to the degradation of the fluid, affecting the performance and longevity of the coupling.

As a general guideline, most fluid couplings are designed to operate within a temperature range of -30°C to 80°C (-22°F to 176°F). However, the actual temperature limitations may vary depending on the manufacturer and the application requirements. For specific industrial applications where high-temperature environments are common, fluid couplings with higher temperature tolerances may be available.

It is crucial to consider the operating environment and the power demands of the machinery when selecting a fluid coupling. In applications with extreme temperatures, additional cooling mechanisms such as external cooling fins or cooling water circulation may be employed to maintain the fluid coupling within its safe operating temperature range.

Exceeding the recommended temperature limits can lead to premature wear, reduced efficiency, and even mechanical failure of the fluid coupling. Regular monitoring of the operating temperature and following the manufacturer’s guidelines for maintenance and fluid replacement can help ensure the longevity and reliability of the fluid coupling.

Always consult with the manufacturer or a qualified engineer to determine the specific temperature limitations and suitability of the fluid coupling for your particular application.

Use of Fluid Couplings in Horizontal and Vertical Shaft Arrangements

Yes, fluid couplings can be used in both horizontal and vertical shaft arrangements, providing flexible power transmission solutions for various industrial applications.

1. Horizontal Shaft Arrangements:

In horizontal shaft arrangements, the fluid coupling is installed between the driving and driven shafts, which are positioned horizontally and parallel to each other. The fluid coupling allows torque to be transmitted smoothly from the driving shaft to the driven shaft, enabling the machinery or equipment to start up gradually without abrupt shocks or overloading. This feature is especially beneficial in applications where heavy loads need to be accelerated smoothly, such as conveyors, crushers, and pumps.

2. Vertical Shaft Arrangements:

In vertical shaft arrangements, the fluid coupling is used to connect the driving and driven shafts, which are positioned vertically and aligned on top of each other. The fluid coupling allows for torque transmission and controlled acceleration, just like in horizontal arrangements. Vertical shaft fluid couplings are commonly used in applications such as vertical conveyors, hoists, and elevators, where they provide smooth starting and stopping of the equipment, preventing sudden jolts and reducing stress on the machinery.

Fluid couplings offer versatility in power transmission and are adaptable to various shaft arrangements, making them suitable for a wide range of industrial setups. Whether the application involves horizontal or vertical shafts, fluid couplings play a crucial role in enhancing the performance, safety, and efficiency of power transmission systems.

editor by CX 2024-04-08

China OEM CHINAMFG Customized Fluid Coupling, Hydraulic Couplings

Product Description

Densen Customized Fluid Coupling, Hydraulic Couplings

| Product Name | Densen customized adjust speed fluid coupling,hydraulic flexible fluid couplings,yot fluid coupling |

| DN mm | 225~1312mm |

| Rated Torque | 2000~11950000N·m |

| Allowable speed | 1500~3000 RPM |

| Material | 35CrMo/ZG270/45# steel/Aluminum alloy |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

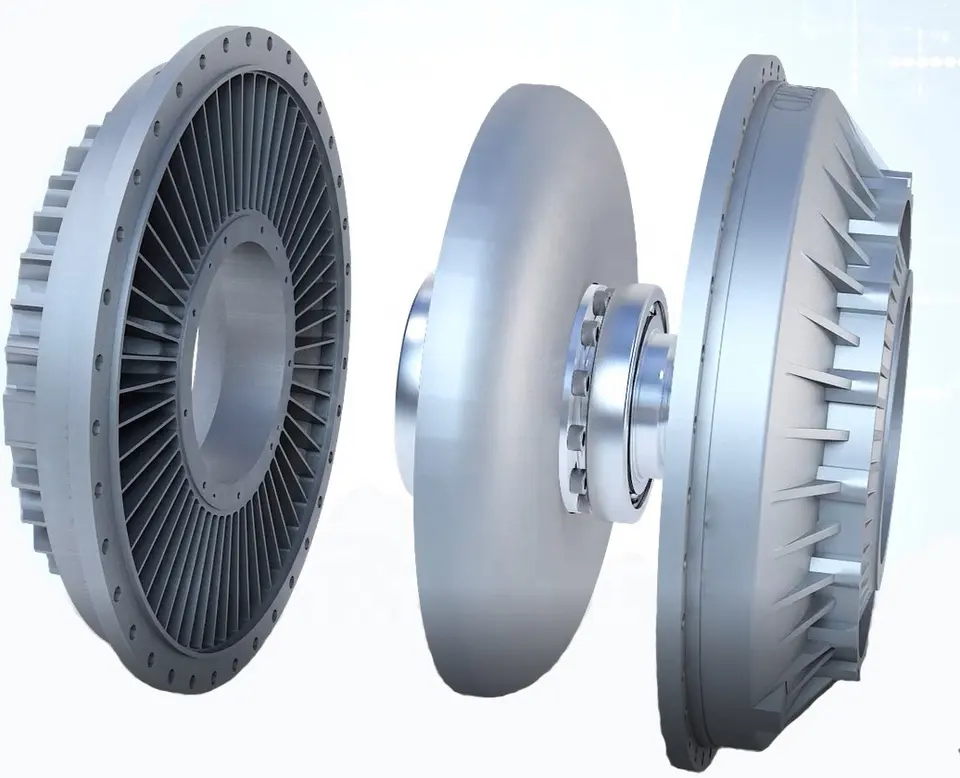

Product show

Company Information

Equipment

Typical case of diaphragm coupling applied to variable frequency speed control equipment

JMB type coupling is applied to HangZhou Oilfield Thermal Power Plant

According to the requirements of HangZhou Electric Power Corporation, HangZhou Oilfield Thermal Power Plant should dynamically adjust the power generation according to the load of the power grid and market demand, and carry out the transformation of the frequency converter and the suction fan. The motor was originally a 1600KW, 730RPM non-frequency variable speed motor matched by HangZhou Motor Factory. The speed control mode after changing the frequency is manual control. Press the button speed to increase 10RPM or drop 10RPM. The coupling is still the original elastic decoupling coupling, and the elastic de-coupling coupling after frequency conversion is frequently damaged, which directly affects the normal power generation.

It is found through analysis that in the process of frequency conversion speed regulation, the pin of the coupling can not bear the inertia of the speed regulation process (the diameter of the fan impeller is 3.3 meters) and is cut off, which has great damage to the motor and the fan.

Later, they switched to the JMB460 double-diaphragm wheel-type coupling of our factory (patent number: ZL.99246247.9). After 1 hour of destructive experiment and more than 1 year of operation test, the equipment is running very well, and there is no Replace the diaphragm. 12 units have been rebuilt and the operation is in good condition.

Other Application Case

Spare parts

Packaging & Shipping

Contact us /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can you explain the Concept of Slip in a Fluid Coupling?

In a fluid coupling, slip refers to the relative speed difference between the impeller and the runner. When the impeller, which is connected to the driving shaft, rotates, it induces the flow of hydraulic fluid inside the coupling. This fluid flow in turn drives the rotation of the runner, which is connected to the driven shaft.

However, due to the operating principle of fluid couplings, there is always a certain amount of slip between the impeller and the runner. This slip occurs because the fluid coupling needs to allow for a small speed difference in order to transmit torque smoothly.

During startup or under heavy load conditions, the impeller’s rotational speed may be slightly higher than the runner’s rotational speed. This speed difference causes the hydraulic fluid to circulate between the impeller and the runner, generating hydrodynamic forces that transmit torque from the driving shaft to the driven shaft.

Slip is an inherent and controlled characteristic of fluid couplings, and it is essential for their smooth operation. However, excessive slip can lead to energy losses and reduced efficiency. Therefore, fluid couplings are designed to have an optimal slip value for specific applications, balancing the need for torque transmission and energy efficiency.

Role of Fluid Coupling in Torque Multiplication and Power Transfer

A fluid coupling is a mechanical device used to transmit power between two shafts without direct physical contact. It operates on the principles of fluid dynamics and hydrokinetics to enable torque multiplication and efficient power transfer. Here’s how a fluid coupling achieves these functions:

- Hydrodynamic Torque Converter: A fluid coupling is essentially a hydrodynamic torque converter. When the input shaft (driving shaft) rotates, it sets the transmission fluid inside the coupling in motion. The fluid experiences centrifugal forces, creating a high-velocity zone near the outer circumference and a low-velocity zone near the center. This velocity difference generates torque in the fluid coupling, allowing power to be transmitted from the input shaft to the output shaft (driven shaft).

- Torque Multiplication: One of the primary advantages of a fluid coupling is its ability to provide torque multiplication. During startup or when the load on the driven shaft is initially low, the fluid coupling slips to some extent, which allows the input shaft to rotate at a higher speed than the output shaft. This speed difference results in torque multiplication, enabling the fluid coupling to handle higher loads during acceleration or heavy starting conditions.

- Power Transfer Efficiency: Fluid couplings offer high power transfer efficiency due to the hydrodynamic nature of their operation. The smooth and continuous transmission of power through the fluid medium minimizes energy losses and mechanical wear, leading to more efficient power transmission compared to mechanical clutches or direct-coupling methods.

- Load Adaptability: Fluid couplings automatically adjust their slip to adapt to changing load conditions. When the load on the output shaft increases, the fluid coupling slips more, allowing the output shaft to slow down slightly and match the load demand. This load adaptability ensures smooth and stable power transfer even under varying operating conditions.

Fluid couplings are commonly used in applications where torque multiplication and smooth power transfer are essential. They find widespread use in heavy machinery, mining equipment, conveyors, crushers, marine propulsion systems, and many other industrial applications. By efficiently transferring power while providing torque multiplication, fluid couplings help optimize the performance and longevity of power transmission systems.

Proper selection of the fluid coupling based on the application’s torque and power requirements is crucial to ensure optimal torque multiplication and power transfer. Additionally, regular maintenance and monitoring of the fluid coupling’s condition are essential to maintain its efficiency and reliability over time.

Safety Considerations when Working with Fluid Couplings

Fluid couplings are essential components in various industrial applications, and it’s essential to follow safety guidelines when working with them. Here are some safety considerations:

- Lockout-Tagout (LOTO): Before performing any maintenance or repair work on a fluid coupling, ensure that the equipment is properly shut down and that the energy sources are locked out and tagged out. This prevents accidental startup and protects personnel from potential hazards.

- Fluid Containment: When draining or replacing the fluid in a fluid coupling, use appropriate containers to collect and contain the fluid. Avoid spills, as some coupling fluids may be hazardous.

- High Temperatures: Fluid couplings can reach high temperatures during operation. Allow sufficient cooling time before handling or inspecting the coupling to avoid burns or injuries.

- Personal Protective Equipment (PPE): Wear appropriate PPE, such as gloves and eye protection, when working with fluid couplings to protect against potential splashes or contact with hot surfaces.

- Manufacturer Recommendations: Follow the safety guidelines and instructions provided by the fluid coupling manufacturer for installation, maintenance, and troubleshooting.

- Proper Tools: Use the correct tools and equipment for maintenance and assembly tasks to prevent damage to the fluid coupling and ensure safe working conditions.

- Training: Ensure that personnel working with fluid couplings are adequately trained in their proper use, maintenance, and safety procedures.

- Inspections: Regularly inspect the fluid coupling for any signs of wear, leaks, or abnormalities that could pose safety risks. Address any issues promptly.

- Hot Work: Avoid performing hot work (e.g., welding, cutting) in the vicinity of fluid couplings, as the high-temperature fluids and components may present a fire hazard.

- Consult Experts: If in doubt or facing complex issues with fluid couplings, consult qualified experts or the manufacturer for guidance.

Adhering to these safety considerations will help minimize risks and ensure a safe working environment when dealing with fluid couplings.

editor by CX 2024-02-11