Product Description

Product Description

Aluminum Compressed Air Pipe

Introducing the Aluminum Compressed Air Pipe by HangZhou CHINAMFG Fluid Technology Co., Ltd. This isometric direct connection is a common and effective way of connecting pipes, providing numerous benefits for your compressed air system.

Features:

- Simple and fast installation

- Tight and reliable connection

- Low resistance and pressure loss

Benefits:

With the Aluminum Compressed Air Pipe, installation becomes a breeze. The direct butt jointing of pipes eliminates the need for additional joints or connecting devices, saving you time and labor costs. Simply align and tightly connect 2 aluminum pipes of equal diameter to complete the connection.

Furthermore, the equal diameter direct connection method ensures the tightness and reliability of the pipe connection. By following the proper connection process and technology, the pipes can be completely sealed, effectively preventing compressed air leakage. This tight connection keeps your system running efficiently, improving overall working efficiency.

In addition, the aluminum alloy construction of the pipe contributes to its low resistance and pressure loss. Without any additional joints or connecting devices, the flow inside the pipe experiences minimal resistance, resulting in relatively low pressure loss. This not only improves air transfer efficiency but also reduces energy consumption, making it an environmentally friendly choice.

Choose the Aluminum Compressed Air Pipe for a hassle-free installation, reliable connections, and improved efficiency in your compressed air system.

Product Parameters

| S.N | Norminal diameter (mm) | W(mm) | H(mm) | |

| DN20 | 48 | 52 | ||

| DN25 | 53 | 52 | ||

| DN40 | 81 | 75 | ||

| DN50 | 91 | 75 | ||

| DN65 | 124 | 106 | ||

| DN80 | 141 | 106 | ||

| DN100 | 158 | 106 | ||

| DN125 | 181 | 106 | ||

| CC 5710 30 | DN148 | 225 | 130 | |

| BB 5710 30 | DN200 | 281 | 130 |

Hot Products

| Photo | Product Name | Product Parmeters | Details |

| Aluminum Pipe | DN20-DN200 | Click on | |

| 90 Degree Elbow | DN20(Assembly) DN25(Assembly) DN20-DN200 | Click on | |

| Equal Flange | DN20-DN200 | Click on | |

| Equal Tee | DN20-DN200 | Click on | |

| Quick Drop | Multiple models available | Click on | |

| Tubine Butterfly Valve | DN65-DN200 | Click on |

| 1. Complete Reliability | Removable and reusable components, perfect for your factory environment Fast installation of shunt device and branch pipeline, convenient adjustment of production line Rich interfaces and accessories, suitable for any system All components are nonflammable |

| 2. Better Corrosion Resistance than 304 Stainless Steel | Anti-corrosion Internal Surface Treatment of Aluminum Alloy Pipe Alkali and acid corrosion resistance Internal surface always clean, no pressure loss of the pipe network system |

| 3. Easy Operation | Pipelines and connectors can be installed immediately without additional treatment — no pre construction preparation is required Fast assembly, no welding, gluing or stranding required – time saving Easy assembley- no need for training Light weight, easy for cutting pipes — easier to work on site Directly use — the system can be tested and used immediately |

| 4. Energy Saving | Consistently high quality interior surfaces – clean air Low friction of inner surface — high flow performance Precise pipe diameter – optimized sealing Automatic filling type large contact surface sealing system ,no leakage |

| 5. Excellent Resistance against the Following Environments | Corrosion Mechanical vibration Thermal variations U.V Compressor oil |

| 6. Durable, Beauty | Electrostatic spraying when leaving the factory Standard color, beautiful appearance |

Product Category & Application

HangZhou CHINAMFG Fluid Technology Co., Ltd. offers a sustainable, efficient, and energy-efficient fluid transportation system. Our Air Compressor Room Industrial Fluid Delivery System features a Pipe to Pipe Equal Coupling, providing a reliable connection for your plumbing needs. With a ten-year quality guarantee, our Press Connection ensures long-lasting performance. Explore our range of pipe fittings, couplings, connectors, and more for all your fluid transportation needs.

Company Profile

HangZhou CHINAMFG Fluid Technology Co., Ltd.

HangZhou CHINAMFG Fluid Technology Co., Ltd. is a manufacturing company specializing in aluminum pipe, pipe fitting, and industrial aluminum profile. We are dedicated to research and development, production, sales, and installation. Our company is located in the economic and technological development zone of HangZhou, ZheJiang , with a spacious floor space of 200 mu and a total investment of 180 million yuan.

With our state-of-the-art production and inspection equipment, including a mold center, inspection center, and R&D equipment imported from Germany, South Korea, and Japan, we have become a large-scale aluminum alloy manufacturer with first-class technical equipment.

Our production facilities include 5 aluminum alloy tube extrusion production lines, 3 deep processing production lines for finished products, and 2 production lines for industrial aluminum profile. This enables us to have an annual production capacity of 3,000 tons of aluminum alloy pipe and 8,000 tons of industrial aluminum profile.

At HangZhou CHINAMFG Fluid Technology Co., Ltd., we are committed to delivering high-quality products that meet the needs of our customers. Our aluminum pipes, pipe fittings, and industrial aluminum profiles are designed to provide durability, reliability, and excellent performance. Whether you require aluminum components for industrial applications or other purposes, our products are the perfect choice.

Choose HangZhou CHINAMFG Fluid Technology Co., Ltd. for all your aluminum pipe, pipe fitting, and industrial aluminum profile needs. Contact us today to learn more about our products and services.

HangZhou CHINAMFG Fluid Technology Co., Ltd.

The company specializes in the innovation and deep processing of non-ferrous materials. We are proud to introduce our range of high-quality and diversified products that cater to the demands of customers worldwide.

Product Description:

- High Intensity Aluminum Alloy Pipe: Our high-intensity aluminum alloy pipe is designed to meet the highest standards of durability and strength. It is perfect for applications that require a lightweight yet robust solution.

- Stainless-Steel Pipe: Our stainless-steel pipe is crafted with precision and offers excellent corrosion resistance. It is ideal for industries where hygiene and longevity are paramount.

- Copper-Aluminum Composite Pipe: Our copper-aluminum composite pipe combines the best properties of both materials. It provides superior heat transfer and is widely used in heating and cooling systems.

- Aluminum Pipe with Internal Thread: Our aluminum pipe with internal thread is designed for easy installation and connection. It is suitable for various plumbing and fluid transfer applications.

- High-Frequency Welding of Aluminum Alloy Collector Pipe and Pipe Fittings: Our high-frequency welding technology ensures seamless joints and enhances the overall performance of the collector pipe and pipe fittings. It is a reliable choice for efficient fluid transportation.

With our commitment to innovation and customer satisfaction, we strive to deliver products that exceed expectations. Choose HangZhou CHINAMFG Fluid Technology Co., Ltd. for a wide range of high-quality and diversified non-ferrous material products.

Our Customers

HangZhou CHINAMFG Fluid Technology Co., Ltd.

At HangZhou CHINAMFG Fluid Technology Co., Ltd., we are dedicated to continuously improving the reliability and durability of our products through sustained innovation in design. Our complete innovation process, strict working condition design, and rigorous quality control measures ensure the production of high-quality products.

With JIEU, you can expect powerful technical support for every project, while minimizing your costs. We offer the perfect total solution for fluid transportation, allowing you to achieve optimal return on investment and safeguard efficient productivity.

Exhibition

Certifications

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Fluid Couplings in Conjunction with Electric Motors

Yes, fluid couplings can be used in conjunction with electric motors to provide a reliable and efficient power transmission solution. When coupled with an electric motor, the fluid coupling serves as a mechanical torque converter, enabling smooth start-ups and gradual acceleration of the driven load.

The combination of a fluid coupling and an electric motor offers several advantages:

- Soft Start: When the electric motor is switched on, it accelerates gradually as the fluid coupling allows the torque to build up slowly. This soft start feature reduces mechanical stress on the driven equipment and minimizes the impact on the electrical supply, preventing voltage drops and surges.

- Overload Protection: Fluid couplings can automatically disengage when the load exceeds a certain threshold, providing overload protection to both the motor and the driven equipment. This feature helps prevent damage to the system during abrupt load changes or stall conditions.

- Vibration Damping: The fluid in the coupling acts as a damping medium, reducing vibration and shock loads during start-ups and sudden load changes. This contributes to smoother operation and extends the lifespan of the connected machinery.

- Energy Efficiency: By facilitating soft start and controlling torque transmission, fluid couplings improve the energy efficiency of the system. They reduce the inrush current during start-up, which can lead to significant energy savings in the long run.

- Variable Speed Control: In some configurations, fluid couplings can be combined with Variable Frequency Drives (VFDs) to provide variable speed control. The VFD regulates the speed of the electric motor, while the fluid coupling ensures smooth and controlled power transmission to the driven equipment.

Overall, the combination of a fluid coupling with an electric motor is a versatile solution that finds applications in various industries. It allows for reliable and controlled power transmission, protecting both the motor and the driven equipment while improving system efficiency.

Fluid Couplings in High-Temperature Environments

Fluid couplings are versatile power transmission devices commonly used in various industrial applications. However, their suitability for high-temperature environments depends on several factors, including the design, materials, and the specific operating conditions.

Here are some key considerations regarding the use of fluid couplings in high-temperature environments:

- Fluid Type: The type of fluid used inside the coupling greatly influences its temperature capabilities. Some fluid couplings are designed to handle higher temperatures by using specially formulated high-temperature fluids that can withstand elevated heat levels without degradation.

- Materials: The materials used in the construction of the fluid coupling play a crucial role in determining its maximum temperature tolerance. High-quality materials with good heat resistance properties are required to ensure reliable performance in high-temperature conditions.

- Lubrication: Proper lubrication is essential to reduce friction and heat generation within the fluid coupling. In high-temperature environments, ensuring sufficient and appropriate lubrication is crucial to prevent excessive wear and potential damage.

- Cooling: Some fluid couplings come equipped with cooling systems, such as cooling fins or external cooling circuits, to dissipate excess heat generated during operation. These cooling mechanisms can enhance the coupling’s capacity to handle higher temperatures.

- Application Considerations: The specific application and load requirements must be taken into account. In some cases, high-temperature conditions may be intermittent or occasional, allowing the fluid coupling to cool down between cycles. However, continuous high-temperature operation may require a more robust and specialized fluid coupling.

It is important to consult with the fluid coupling manufacturer to understand the temperature limitations and performance capabilities of their products. Manufacturers can provide guidance on selecting the appropriate fluid coupling for specific high-temperature applications.

While fluid couplings can be suitable for moderate to high-temperature environments, it is essential to operate them within their specified temperature range to ensure optimal performance and longevity. Extreme temperatures beyond the coupling’s rated limits can lead to accelerated wear, reduced efficiency, and potential damage, ultimately affecting the reliability of the power transmission system.

In summary, fluid couplings can be used in high-temperature environments, provided that the coupling’s design, materials, and lubrication are suitable for the specific application and operating conditions. Regular maintenance and adherence to the manufacturer’s guidelines are essential to ensure reliable performance and durability in such environments.

Types of Fluid Used in Fluid Couplings

Various types of fluids can be used in fluid couplings depending on the specific application and requirements. Some common types of fluids used in fluid couplings include:

- Oil: Mineral oil is one of the most commonly used fluids in fluid couplings. It offers good lubrication properties and thermal stability, making it suitable for a wide range of operating conditions. Oil-based fluids are generally cost-effective and readily available.

- Water-Glycol: Water-glycol mixtures are often used in fluid couplings that require fire-resistant properties. These mixtures provide improved cooling and are less flammable compared to pure oil fluids. They are commonly used in applications where fire safety is a concern, such as in mining and underground operations.

- Synthetic Fluids: Synthetic fluids, such as synthetic oils and silicone-based fluids, offer enhanced performance characteristics over mineral oils. They can withstand higher temperatures and provide better thermal stability, making them suitable for more demanding industrial applications.

- Biodegradable Fluids: In environmentally sensitive applications, biodegradable fluids are used to reduce the environmental impact in case of accidental leaks or spills. These fluids are designed to break down naturally and are commonly used in applications like forestry and marine operations.

The choice of fluid depends on factors such as the required power transmission efficiency, operating temperature, fire safety requirements, and environmental considerations. It is essential to select the appropriate fluid that matches the specific needs of the fluid coupling and the machinery or equipment it is used in.

editor by CX 2024-03-15

China Custom Air Compressor Room Industrial Fluid Delivery System Pipe to Pipe Equal Coupling

Product Description

Product Description

Aluminum Compressed Air Pipe

Introducing the Aluminum Compressed Air Pipe by HangZhou CHINAMFG Fluid Technology Co., Ltd. This isometric direct connection is a common and effective way of connecting pipes, providing numerous benefits for your compressed air system.

Features:

- Simple and fast installation

- Tight and reliable connection

- Low resistance and pressure loss

Benefits:

With the Aluminum Compressed Air Pipe, installation becomes a breeze. The direct butt jointing of pipes eliminates the need for additional joints or connecting devices, saving you time and labor costs. Simply align and tightly connect 2 aluminum pipes of equal diameter to complete the connection.

Furthermore, the equal diameter direct connection method ensures the tightness and reliability of the pipe connection. By following the proper connection process and technology, the pipes can be completely sealed, effectively preventing compressed air leakage. This tight connection keeps your system running efficiently, improving overall working efficiency.

In addition, the aluminum alloy construction of the pipe contributes to its low resistance and pressure loss. Without any additional joints or connecting devices, the flow inside the pipe experiences minimal resistance, resulting in relatively low pressure loss. This not only improves air transfer efficiency but also reduces energy consumption, making it an environmentally friendly choice.

Choose the Aluminum Compressed Air Pipe for a hassle-free installation, reliable connections, and improved efficiency in your compressed air system.

Product Parameters

| S.N | Norminal diameter (mm) | W(mm) | H(mm) | |

| DN20 | 48 | 52 | ||

| DN25 | 53 | 52 | ||

| DN40 | 81 | 75 | ||

| DN50 | 91 | 75 | ||

| DN65 | 124 | 106 | ||

| DN80 | 141 | 106 | ||

| DN100 | 158 | 106 | ||

| DN125 | 181 | 106 | ||

| CC 5710 30 | DN148 | 225 | 130 | |

| BB 5710 30 | DN200 | 281 | 130 |

| 1. Complete Reliability | Removable and reusable components, perfect for your factory environment Fast installation of shunt device and branch pipeline, convenient adjustment of production line Rich interfaces and accessories, suitable for any system All components are nonflammable |

| 2. Better Corrosion Resistance than 304 Stainless Steel | Anti-corrosion Internal Surface Treatment of Aluminum Alloy Pipe Alkali and acid corrosion resistance Internal surface always clean, no pressure loss of the pipe network system |

| 3. Easy Operation | Pipelines and connectors can be installed immediately without additional treatment — no pre construction preparation is required Fast assembly, no welding, gluing or stranding required – time saving Easy assembley- no need for training Light weight, easy for cutting pipes — easier to work on site Directly use — the system can be tested and used immediately |

| 4. Energy Saving | Consistently high quality interior surfaces – clean air Low friction of inner surface — high flow performance Precise pipe diameter – optimized sealing Automatic filling type large contact surface sealing system ,no leakage |

| 5. Excellent Resistance against the Following Environments | Corrosion Mechanical vibration Thermal variations U.V Compressor oil |

| 6. Durable, Beauty | Electrostatic spraying when leaving the factory Standard color, beautiful appearance |

Product Category & Application

HangZhou CHINAMFG Fluid Technology Co., Ltd. offers a sustainable, efficient, and energy-efficient fluid transportation system. Our Air Compressor Room Industrial Fluid Delivery System features a Pipe to Pipe Equal Coupling, providing a reliable connection for your plumbing needs. With a ten-year quality guarantee, our Press Connection ensures long-lasting performance. Explore our range of pipe fittings, couplings, connectors, and more for all your fluid transportation needs.

Company Profile

HangZhou CHINAMFG Fluid Technology Co., Ltd.

HangZhou CHINAMFG Fluid Technology Co., Ltd. is a manufacturing company specializing in aluminum pipe, pipe fitting, and industrial aluminum profile. We are dedicated to research and development, production, sales, and installation. Our company is located in the economic and technological development zone of HangZhou, ZheJiang , with a spacious floor space of 200 mu and a total investment of 180 million yuan.

With our state-of-the-art production and inspection equipment, including a mold center, inspection center, and R&D equipment imported from Germany, South Korea, and Japan, we have become a large-scale aluminum alloy manufacturer with first-class technical equipment.

Our production facilities include 5 aluminum alloy tube extrusion production lines, 3 deep processing production lines for finished products, and 2 production lines for industrial aluminum profile. This enables us to have an annual production capacity of 3,000 tons of aluminum alloy pipe and 8,000 tons of industrial aluminum profile.

At HangZhou CHINAMFG Fluid Technology Co., Ltd., we are committed to delivering high-quality products that meet the needs of our customers. Our aluminum pipes, pipe fittings, and industrial aluminum profiles are designed to provide durability, reliability, and excellent performance. Whether you require aluminum components for industrial applications or other purposes, our products are the perfect choice.

Choose HangZhou CHINAMFG Fluid Technology Co., Ltd. for all your aluminum pipe, pipe fitting, and industrial aluminum profile needs. Contact us today to learn more about our products and services.

HangZhou CHINAMFG Fluid Technology Co., Ltd.

The company specializes in the innovation and deep processing of non-ferrous materials. We are proud to introduce our range of high-quality and diversified products that cater to the demands of customers worldwide.

Product Description:

- High Intensity Aluminum Alloy Pipe: Our high-intensity aluminum alloy pipe is designed to meet the highest standards of durability and strength. It is perfect for applications that require a lightweight yet robust solution.

- Stainless-Steel Pipe: Our stainless-steel pipe is crafted with precision and offers excellent corrosion resistance. It is ideal for industries where hygiene and longevity are paramount.

- Copper-Aluminum Composite Pipe: Our copper-aluminum composite pipe combines the best properties of both materials. It provides superior heat transfer and is widely used in heating and cooling systems.

- Aluminum Pipe with Internal Thread: Our aluminum pipe with internal thread is designed for easy installation and connection. It is suitable for various plumbing and fluid transfer applications.

- High-Frequency Welding of Aluminum Alloy Collector Pipe and Pipe Fittings: Our high-frequency welding technology ensures seamless joints and enhances the overall performance of the collector pipe and pipe fittings. It is a reliable choice for efficient fluid transportation.

With our commitment to innovation and customer satisfaction, we strive to deliver products that exceed expectations. Choose HangZhou CHINAMFG Fluid Technology Co., Ltd. for a wide range of high-quality and diversified non-ferrous material products.

Our Customers

HangZhou CHINAMFG Fluid Technology Co., Ltd.

At HangZhou CHINAMFG Fluid Technology Co., Ltd., we are dedicated to continuously improving the reliability and durability of our products through sustained innovation in design. Our complete innovation process, strict working condition design, and rigorous quality control measures ensure the production of high-quality products.

With JIEU, you can expect powerful technical support for every project, while minimizing your costs. We offer the perfect total solution for fluid transportation, allowing you to achieve optimal return on investment and safeguard efficient productivity.

Exhibition

Certifications

After Sales Service

UPIPE Series Product – Ten-year Quality Guarantee

HangZhou CHINAMFG Fluid Technology Co., Ltd. offers a ten-year quality guarantee for the UPIPE series product. Within 10 years from the installation and acceptance of the product, we will replace or repair it free of charge in case of any quality problems.

Please note that the following reasons are not covered under the guarantee:

- The product or component is out of the warranty period, except for products with extended quality assurance service.

- The product has not been installed according to our stipulations or has exceeded the applicable scope specified by our company. It must be operated in accordance with our company’s manual and the requirements of the relevant installation and maintenance documents. Additionally, it should not be used in a working environment that goes against our stipulations. The guarantee does not cover damage caused by improper installation, storage, or operation, such as exposure to excessively high or low ambient temperatures, corrosive environments, or external forces.

- The breakdown or damage caused by unauthorized installation, repair, modification, or dismounting performed by our company’s after-sales personnel or the designated service agent, except for the third-party after-sales service agency entrusted by the company.

Choose UPIPE series products for their exceptional quality and enjoy peace of mind with our ten-year quality guarantee.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Advancements and Innovations in Fluid Coupling Technology

Fluid coupling technology has undergone significant advancements and innovations over the years, leading to improved performance, efficiency, and versatility. Some notable advancements include:

- Variable Fill Fluid Couplings: These modern fluid couplings feature a variable fill design that allows for better control of the power transmission. By adjusting the fill level of the coupling, it becomes possible to optimize torque transmission and efficiency across a wider range of operating conditions.

- Electronic Control: The integration of electronic control systems has brought a new level of intelligence to fluid couplings. Electronic control allows for precise monitoring and adjustment of the coupling’s operation, enabling smoother start-ups, better load sharing, and protection against excessive loads.

- Smart Coupling Technologies: Some fluid coupling manufacturers offer smart coupling technologies that incorporate sensors and data analytics. These smart couplings can monitor performance parameters in real-time, detect anomalies, and provide valuable insights into the overall system health.

- High-Temperature Applications: Advancements in material science have led to the development of fluid couplings capable of operating at higher temperatures. This makes them suitable for use in demanding applications, such as heavy industries and high-temperature environments.

- Efficiency Improvements: Manufacturers have focused on enhancing the overall efficiency of fluid couplings. By reducing internal losses and improving fluid circulation, modern fluid couplings offer higher efficiency, which translates into energy savings and reduced operating costs.

- Integration with Variable Frequency Drives (VFDs): Fluid couplings can now be integrated with VFDs, combining the benefits of both technologies. The VFD allows for variable speed control, while the fluid coupling provides soft start and overload protection, creating a versatile and efficient power transmission system.

These advancements in fluid coupling technology have made them even more reliable, adaptable, and suitable for various industrial applications. As technology continues to evolve, fluid couplings are likely to see further improvements, making them an integral part of modern power transmission systems.

Cost Implications of Using Fluid Couplings in Comparison to Other Power Transmission Methods

The cost implications of using fluid couplings in power transmission depend on various factors, including the application requirements, the size of the system, and the operational conditions. While fluid couplings offer several advantages, they may have different cost considerations compared to other power transmission methods like mechanical clutches, VFDs (Variable Frequency Drives), and direct mechanical drives.

1. Initial Investment:

The initial cost of a fluid coupling can be higher than that of a mechanical clutch or a direct mechanical drive. Fluid couplings contain precision components, including the impeller and turbine, which can impact their initial purchase price.

2. Maintenance Costs:

Fluid couplings are generally considered to have lower maintenance costs compared to mechanical clutches. Mechanical clutches have wear and tear components that may require more frequent replacements, leading to higher maintenance expenses over time.

3. Energy Efficiency:

Fluid couplings are highly efficient in power transmission, especially during soft-start applications. Their ability to reduce shock loads and provide a smooth acceleration can result in energy savings and operational cost reductions.

4. Space and Weight:

Fluid couplings are usually more compact and lighter than some mechanical clutches, which can be advantageous in applications with space constraints or weight limitations.

5. Specific Application Considerations:

The suitability and cost-effectiveness of fluid couplings versus other power transmission methods can vary based on specific application requirements. For example, in soft-start applications, fluid couplings may be the preferred choice due to their ability to reduce mechanical stress and protect connected equipment.

6. Lifespan and Reliability:

While the initial cost of a fluid coupling might be higher, their longevity and reliability can lead to lower overall life cycle costs compared to other power transmission methods.

In conclusion, the cost implications of using fluid couplings in power transmission depend on the particular application and the total cost of ownership over the equipment’s lifespan. Although fluid couplings may have a higher initial investment, their long-term reliability, energy efficiency, and lower maintenance costs can make them a cost-effective choice in many industrial applications.

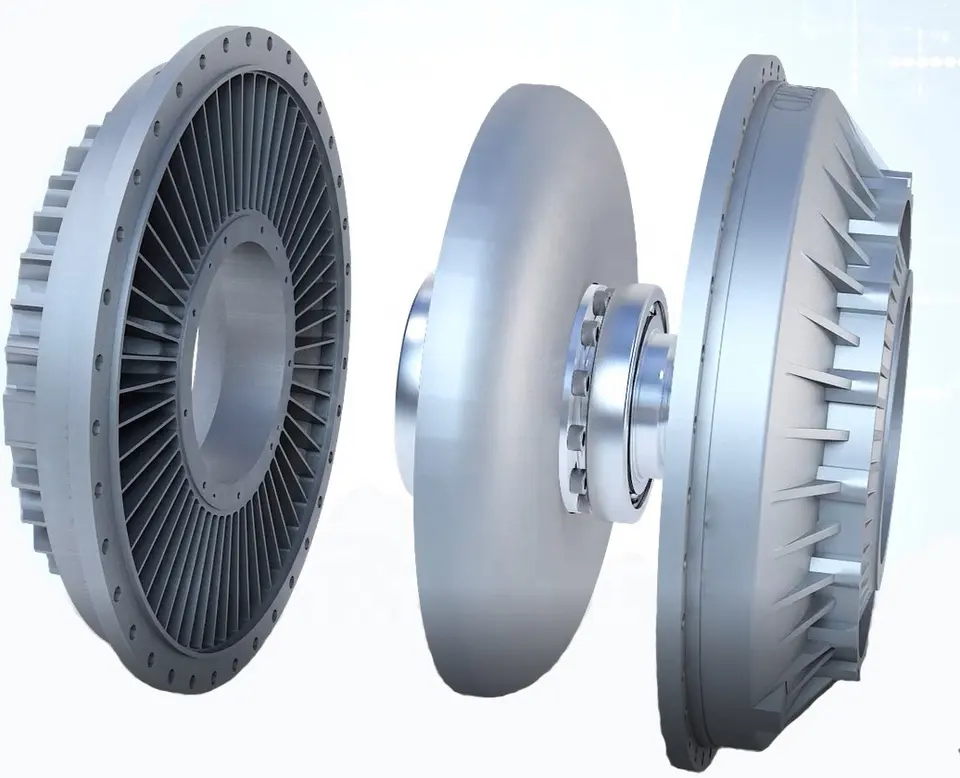

Key Components of a Fluid Coupling and Their Functions

A fluid coupling consists of several essential components that work together to transfer torque and facilitate smooth power transmission. The key components and their functions are as follows:

- Impeller: The impeller is the primary input element of the fluid coupling. It is directly connected to the driving shaft and rotates with it. The impeller’s function is to churn and circulate the fluid inside the coupling, creating a flow that generates a hydrodynamic torque.

- Runner/Turbine: The runner, also known as the turbine, is the output element of the fluid coupling. It is connected to the driven shaft and rotates with it. As the fluid from the impeller flows onto the runner, it causes the runner to rotate and transmit torque to the driven load.

- Fluid: The fluid, typically hydraulic oil, is the medium that transmits torque from the impeller to the runner. It fills the space between the impeller and the runner and allows the torque transfer to take place through hydrodynamic action.

- Filler Plug: The filler plug is used to add or drain the fluid from the fluid coupling. It allows for the adjustment of fluid levels, which can influence the coupling’s performance characteristics.

- Seal Ring: The seal ring prevents the fluid from leaking out of the fluid coupling and ensures that the coupling operates with maximum efficiency and minimal losses.

- Bearing: The bearing provides support for the input and output shafts, allowing them to rotate smoothly. Bearings are critical for maintaining alignment and reducing friction within the fluid coupling.

These key components work together to create a hydrodynamic torque transfer, enabling the fluid coupling to smoothly transmit power and torque from the driving shaft to the driven shaft without any physical contact between the two shafts.

editor by CX 2024-02-13

China Good quality Air Compressor Room Industrial Fluid Delivery System Pipe to Pipe Equal Coupling

Product Description

Product Description

| System Advantages: | Product Advantages: |

| -Better Performance | -Sleek internal surface |

| -Higher Sustainability | -Low pressure loss for the arc bending |

| -More Efficient | -Full bore design pipe fitting |

| -More Flexible Access | -Safe connection with bulge loop and staple bolt |

| -Better Energy Efficiency | -Spatial active sealing technology |

| -Gooseneck type quick connection mode |

| 1. Complete Reliability | Removable and reusable components, perfect for your factory environment Fast installation of shunt device and branch pipeline, convenient adjustment of production line Rich interfaces and accessories, suitable for any system All components are nonflammable |

| 2. Better Corrosion Resistance than 304 Stainless Steel | Anti-corrosion Internal Surface Treatment of Aluminum Alloy Pipe Alkali and acid corrosion resistance Internal surface always clean, no pressure loss of the pipe network system |

| 3. Easy Operation | Pipelines and connectors can be installed immediately without additional treatment — no pre construction preparation is required Fast assembly, no welding, gluing or stranding required – time saving Easy assembley- no need for training Light weight, easy for cutting pipes — easier to work on site Directly use — the system can be tested and used immediately |

| 4. Energy Saving | Consistently high quality interior surfaces – clean air Low friction of inner surface — high flow performance Precise pipe diameter – optimized sealing Automatic filling type large contact surface sealing system ,no leakage |

| 5. Excellent Resistance against the Following Environments | Corrosion Mechanical vibration Thermal variations U.V Compressor oil |

| 6. Durable, Beauty | Electrostatic spraying when leaving the factory Standard color, beautiful appearance |

Product Parameters

Product Category & Application

Upipe dedicates to the sustainable, efficient and energy efficiency fluid transportation system

Company Profile

HangZhou JIEU FLUID TECHNOLOGYCO., LTD. is a manufacturing company specialized in aluminum pipe, pipe fitting and industrial aluminum profile, which integrated in R&D, production, sales and installation. The group locates at economic and technological development zone of HangZhou, ZheJiang , with a floor space of 200 mu and total investment of 180 million yuan. With 5 aluminum alloy tube extrusion production lines, 3 deep processing production line for finished products, and 2 production lines for industrial aluminum profile, the annual production capacity can be 3,000 tons of aluminum alloy pipe and 8,000 tons of industrial aluminum profile. It has become the large-scale aluminum alloy manufacturer with first-class technical equipment as it has the state-of-the-art production and inspection equipment, including mold center, inspection center, R&D and other equipment imported from Germany, South Korea and Japan.

The company engages in the innovation and deep processing of non-ferrous materials and has launched high intensity aluminum alloy pipe, stainless-steel pipe, copper-aluminum composite pipe, aluminum pipe with internal thread, high-frequency welding of aluminum alloy collector pipe and pipe fittings, satisfying the demands of customers across the world with more diversified and better products.

Our Customers

With the sustained innovation in design, JIEU strives to improve the reliability and durability of the products constantly. With the complete innovation, strict working condition design and rigorous quality control, JIEU ensures the production of high-quality products, providing powerful technical support for every project while minimizing your cost. JIEU will offer you with the perfect total solution for the fluid transportation so as to realize the optimal return of investment and safeguard the efficient productivity of customers.

Exhibition

Certifications

After Sales Service

Ten-year quality guarantee

Our company will replace or repair the product free of charge for the quality problem within 10 years from the installation and acceptance of UPIPE series product.

The exclusion clause shall not cover the problem or damage caused by the following reasons, which will be included but not limited to the following:

1. The product or component has been out of the warranty period, except for the product with extended quality assurance service.

2. The product has not been installed according to our stipulation or exceeded the applicable scope stipulated by our company. The product fails to be operated according to our company’s manual and requirements of pertinent installation and maintenance document or it has been applied in a working environment that is against our stipulation. The damage caused by improper installation, storage or operation (for example, the ambient temperature is too high, too low or in a corrosive environment or hit by external force and so on.)

3. The breakdown or damage caused by unauthorized installation, repair, modification or dismounting performed by our company’s after-sales personnel or the designated service agent, except for the third-party after-sales service agency entrusted by the company.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Maintenance-Free Fluid Coupling Options

Yes, there are maintenance-free fluid coupling options available in the market. Advances in fluid coupling technology have led to the development of maintenance-free or low-maintenance designs that offer extended service intervals and reduced downtime.

These maintenance-free fluid couplings typically incorporate features that minimize wear and prolong the operating life of the coupling, reducing the need for regular maintenance and lubrication.

Some of the key features and technologies found in maintenance-free fluid couplings include:

- Sealed Design: Maintenance-free fluid couplings often come with a sealed design that prevents the ingress of contaminants and dirt, reducing the risk of internal damage and wear.

- High-Quality Materials: These couplings are constructed using high-quality materials that exhibit excellent durability and resistance to wear, ensuring a longer lifespan.

- Lubrication-Free Operation: Certain maintenance-free fluid couplings utilize special fluid formulations that provide long-lasting lubrication, eliminating the need for frequent fluid changes or refills.

- Robust Bearings: Maintenance-free fluid couplings are equipped with robust bearings that can withstand high loads and operate smoothly without the need for regular maintenance.

- Advanced Monitoring Systems: Some modern fluid couplings are equipped with advanced monitoring and diagnostic systems that provide real-time data on coupling performance, enabling proactive maintenance planning and minimizing unexpected failures.

By opting for a maintenance-free fluid coupling, industries can benefit from reduced maintenance costs, improved reliability, and increased productivity. These couplings are particularly valuable in applications where access to equipment for regular maintenance is challenging or in remote locations where maintenance resources may be limited.

However, it’s essential to note that the specific maintenance requirements may vary depending on the manufacturer and the application. It is advisable to consult with the coupling manufacturer or supplier to select the most suitable maintenance-free fluid coupling based on the operating conditions and requirements of the machinery or equipment.

Temperature Limitations of Fluid Couplings

Fluid couplings, like any mechanical component, have temperature limitations that must be considered to ensure their proper and safe operation. The temperature limitations of fluid couplings are influenced by the type of fluid used inside the coupling, the ambient operating conditions, and the specific design and construction of the coupling.

The primary concern regarding temperature is the heat generated during the operation of the fluid coupling. The heat is a result of friction and fluid shear within the coupling as it transmits power between the input and output shafts. Excessive heat generation can lead to the degradation of the fluid, affecting the performance and longevity of the coupling.

As a general guideline, most fluid couplings are designed to operate within a temperature range of -30°C to 80°C (-22°F to 176°F). However, the actual temperature limitations may vary depending on the manufacturer and the application requirements. For specific industrial applications where high-temperature environments are common, fluid couplings with higher temperature tolerances may be available.

It is crucial to consider the operating environment and the power demands of the machinery when selecting a fluid coupling. In applications with extreme temperatures, additional cooling mechanisms such as external cooling fins or cooling water circulation may be employed to maintain the fluid coupling within its safe operating temperature range.

Exceeding the recommended temperature limits can lead to premature wear, reduced efficiency, and even mechanical failure of the fluid coupling. Regular monitoring of the operating temperature and following the manufacturer’s guidelines for maintenance and fluid replacement can help ensure the longevity and reliability of the fluid coupling.

Always consult with the manufacturer or a qualified engineer to determine the specific temperature limitations and suitability of the fluid coupling for your particular application.

Disadvantages and Limitations of Fluid Couplings

While fluid couplings offer numerous advantages, they also have some disadvantages and limitations that should be considered for specific applications:

- Power Loss: Fluid couplings introduce a power loss due to the slip that occurs during power transmission. This power loss can reduce the overall efficiency of the system, especially in applications with high-speed variations.

- Torque Multiplication: Unlike torque converters, fluid couplings have limited torque multiplication capabilities. They do not provide as much torque increase at low speeds, which may be necessary for certain heavy-load applications.

- Temperature Sensitivity: Fluid couplings are sensitive to temperature changes. In extremely hot or cold conditions, the viscosity of the fluid may vary, affecting the coupling’s performance.

- Fluid Contamination: Contaminants in the fluid can adversely affect the performance and lifespan of the fluid coupling. Regular maintenance and monitoring of the fluid quality are essential to prevent potential issues.

- Speed Limitations: Fluid couplings may have speed limitations in certain applications. High-speed operations can lead to centrifugal forces that may affect the coupling’s behavior.

- Complexity in Control: In some cases, controlling the output speed of the fluid coupling can be more challenging compared to other types of couplings. This complexity may require additional control mechanisms.

- Cost: Fluid couplings can be more expensive than some mechanical couplings, such as belt and chain drives. The initial cost and ongoing maintenance expenses should be considered in the selection process.

Despite these limitations, fluid couplings remain a popular choice in many industrial applications, thanks to their smooth power transmission, overload protection, and torsional vibration damping capabilities. The decision to use a fluid coupling should be based on a thorough understanding of the specific requirements and operating conditions of the machinery or equipment.

editor by CX 2023-12-21

China high quality Compressor Spare Parts 1613982300 Coupling for CZPT 1613982300 cohesion and coupling

Product Description

Compressor spare parts 16139823

Product name : Coupling

Product number : 16139823 coupling for Atlas copco

FAQ

Q1. What’s Minimum Order Quantity of your air compressor part?

The MOQ is 1pc for any air compressor spare parts, need you pay for the delivery cost.

Q2. What’s kind of your packaging for the air compressor part?

Neutral packing or brand pack as your requirement

Q3. Could I get some samples?

Yes, we can provide sample, but not free.

Q4. How long is your Delivery Lead Time ?

If there is stock, the lead time is about 2 WORKING DAYS after we get the payment, if need to be produced, it depens.

Q5. Could you Calculate the shipping cost for me?

Yes, we are honored to do that for you! Before the freight , please well let us know which seaport or airport near your place.

Q6. What’s the delivery way?

Shipping way: air freight, express, sea

Money Gram

Q7. What’s the payment

We accept T/T, western union, Paypal, Alipay pay , Wechat pay , Money Gram

Please advise which is better for you.

| Customized: | Customized |

|---|---|

| Standard Component: | Standard Component |

| Material: | Rubber |

| Category: | Coupling |

| Use for: | Atlas Copco |

| Product Number: | 1613982300 |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Types of Couplings

A coupling is a device used to join two shafts together and transmit power. Its purpose is to join rotating equipment while permitting a degree of end movement and misalignment. There are many types of couplings, and it is important to choose the right one for your application. Here are a few examples of couplings.

Mechanical

The mechanical coupling is an important component in power transmission systems. These couplings come in various forms and can be used in different types of applications. They can be flexible or rigid and operate in compression or shear. In some cases, they are permanently attached to the shaft, while in other cases, they are removable for service.

The simplest type of mechanical coupling is the sleeve coupling. It consists of a cylindrical sleeve with an internal diameter equal to the diameter of the shafts. The sleeve is connected to the shafts by a key that restricts their relative motion and prevents slippage. A few sleeve couplings also have threaded holes to prevent axial movement. This type of coupling is typically used for medium to light-duty torque.

Another type of mechanical coupling is a jaw coupling. It is used in motion control and general low-power transmission applications. This type of coupling does not require lubrication and is capable of accommodating angular misalignment. Unlike other types of couplings, the jaw coupling uses two hubs with intermeshing jaws. The jaw coupling’s spider is typically made of copper alloys. In addition, it is suitable for shock and vibration loads.

Mechanical couplings can be made from a variety of materials. One popular choice is rubber. The material can be natural or chloroprene. These materials are flexible and can tolerate slight misalignment.

Electrical

Electrical coupling is the process in which a single electrical signal is transferred from a nerve cell to another. It occurs when electrical signals from two nerve cells interact with each other in a way similar to haptic transmission. This type of coupling can occur on its own or in combination with electrotonic coupling in gap junctions.

Electrical coupling is often associated with oscillatory behavior of neurons. The mechanism of electrical coupling is complex and is studied mathematically to understand its effect on oscillatory neuron networks. For example, electrical coupling can increase or decrease the frequency of an oscillator, depending on the state of the neuron coupled to it.

The site of coupling is usually the junction of opposing cell membranes. The cellular resistance and the coupling resistance are measured in voltage-clamp experiments. This type of coupling has a specific resistance of 100 O-cm. As a result, the coupling resistance varies with the frequency.

The authors of this study noted that electrotonic coupling depends on the ratio between the resistance of the nonjunctional membranes and the junctional membranes. The voltage attenuation technique helps reveal the differences in resistance and shunting through the intercellular medium. However, it is unclear whether electrotonic coupling is electrostatically mediated.

Electrical coupling has also been suggested to play a role in the intercellular transfer of information. There are many examples that support this theory. A message can be a distinct qualitative or quantitative signal, which results in a gradient in the cells. Although gap junctions are absent at many embryonic interaction sites, increasing evidence suggests a role in information transfer.

Flexible

When it comes to choosing the right Flexible Coupling, there are several factors that you should take into account. Among these factors is the backlash that can be caused by the movement of the coupling. The reason for this problem is the fact that couplings that do not have anti-fungal properties can be easily infected by mold. The best way to avoid this is to pay attention to the moisture content of the area where you are installing the coupling. By following these guidelines, you can ensure the best possible installation.

To ensure that you are getting the most out of your flexible couplings, you must consider their characteristics and how easy they are to install, assemble, and maintain. You should also look for elements that are field-replaceable. Another important factor is the coupling’s torsional rigidity. It should also be able to handle reactionary loads caused by misalignment.

Flexible couplings come in many different types. There are diaphragm and spiral couplings. These couplings allow for axial motion, angular misalignment, and parallel offset. They have one-piece construction and are made from stainless steel or aluminum. These couplings also offer high torsional stiffness, which is beneficial for applications requiring high torques.

Flexible couplings have several advantages over their rigid counterparts. They are designed to handle misalignments of up to seven degrees and 0.025 inches. These characteristics are important in motion control applications. Flexible couplings are also inexpensive, and they do not require maintenance.

Beam

A beam coupling is a type of mechanical coupling, usually one solid piece, that connects two mechanical parts. Its performance is largely determined by the material used. Typical materials include stainless steel, aluminum, Delrin, and titanium. The beam coupling is rated for different speeds and torques. The coupling should be selected according to the application. In addition to the material, the application should also consider the speed and torque of the system.

There are two main types of beam couplings. The first is the helical beam coupling, which has a continuous multi spiral cut. This type of coupling offers a high degree of flexibility and compensates for a high degree of misalignment. The second type of beam coupling is the helical shaft coupling, which has a low torsional stiffness, which makes it ideal for small torque applications.

Another type of beam coupling is the multiple beam design, which combines two beams. It allows for more tolerance in manufacturing and installation and protects expensive components from excessive bearing loads. It also helps keep beams shorter than a single beam coupling. This type of coupling also enables a higher torque capacity and torsional stiffness.

Beam couplings can be manufactured with different materials, including stainless steel and aluminum. The “A” series is available in aluminum and stainless steel and is ideal for general-purpose and light-duty applications. It is also economical and durable. This type of coupling can also be used with low torque pumps or encoder/resolver systems.

Pin & bush

The Pin & bush coupling is a versatile, general-purpose coupling with high tensile bolts and rubber bushes. It can tolerate a wide range of operating temperatures and is suitable for use in oil and water-resistance applications. Its unique design enables it to be used in either direction. In addition, it requires no lubrication.

The pin bush coupling is a fail-safe coupling with a long service life and is used for high-torque applications. It provides torsional flexibility and dampens shocks, making it a flexible coupling that protects equipment and reduces maintenance costs. Its hubs are forged from graded cast iron for strength and durability. Besides, the coupling’s elastomer elements reduce vibration and impact loads. It also accommodates a misalignment of up to 0.5 degrees.

Pin & bush couplings are a popular choice for a variety of different applications. This coupling features a protective flange design that protects the coupling flange from wear and tear. The coupling nut is secured to one flange, while a rubber or leather bush sits between the other flange. Its unique design makes it ideal for use in applications where misalignment is a small factor. The rubber bushing also helps absorb vibration and shock.

Mesh tooth

Mesh tooth couplings are used to transfer torque between two shafts and reduce backlash. However, mesh tooth couplings have some limitations. One disadvantage is the break-away friction factor in the axial direction. This problem is caused by the high contact force between the tooth and gear mesh. This can cause unpredictable forces on the shafts.

In this paper, we present a FEM model for mesh tooth coupling. We first validate the mesh density. To do so, we compute the bolt stress as a uniaxial tensile during the tightening process. We used different mesh sizes and mesh density to validate our results.

The mesh stiffness of gear pairs is influenced by lead crown relief and misalignment. For example, if one tooth is positioned too far in the axis, the mesh stiffness will be decreased. A misaligned gear pair will lose torque capacity. A mesh tooth coupling can be lubricated with oil.

An ideal mesh tooth coupling has no gaps between the teeth, which reduces the risk of uneven wear. The coupling’s quality exposed fasteners include SAE Grade 5 bolts. It also offers corrosion resistance. The couplings are compatible with industrial environments. They also eliminate the need for selective assembly in sleeve couplings.

editor by CX 2023-08-03

Best China manufacturer & factory Air compressor parts With high quality best price

We offer OEM service.

Overview

Quick Details

- Condition:

-

New

- Warranty:

-

Adhering to “Survival by Quality, Development by Technology & Credit”, The company will constantly improve product performance to meet the increasing customer requirements in the rigorous style of work.

1.5 years

- Applicable Industries:

-

Manufacturing Plant, Air compressor parts

- After Warranty Service:

-

Online support

- Local Service Location:

-

none

- Showroom Location:

-

none

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

New Product 2020

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Type:

-

AIR FILTER

Packaging & Delivery

-

Lead Time

: -

Quantity(Units) 1 – 9999 Compared to other types of gears, worm gears are unique and have very distinctive characteristics and uses. This post will focus on the advantages of worm gears. For a list of common worm gear applications, please see worm gear capabilities. >9999 Est. Time(days) 12 To be negotiated

Online Customization

Product Description

|

Ever-power specialist in making all kinds of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm gearboxes, in-line helical gear speed reducers, parallel shaft helical gear reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, pto drive shafts, special reducer & related gear components and other related products, sprockets, hydraulic system, vaccum pumps, fluid coupling, gear racks, chains, timing pulleys, udl speed variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors, shaft collars low backlash worm gearboxes and so on. furthermore, we can produce customized variators, geared motors, electric motors and other hydraulic products according to customers’ drawings.

|

Air compressor parts,Air compressor accessaries,compressor spare parts

We produce many kinds of air compressor parts, welcome calls and emails to inquiry!

Packaging & Shipping

Our Services

Also I would like to take this opportunity to give a brief introduction of our Ever-Power company:

Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china.

We have exported many products to our customers all over the world, we have long-time experience and strong technology support.

Some of our customer :

Italy: COMER,GB GEABOX ,SATI, CHIARAVALLI, AMA , Brevini

Germany: SILOKING ,GKN ,KTS

France: Itfran, Sedies

Brazil: AEMCO ,STU

USA: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

……

-Ø Our Company with over twelve year’s history and 1000 workers and 20 sales.

-Ø With over 100 Million USD sales in 2017

-Ø With advance machinery equipments

-Ø With large work capacity and high quality control, ISO certified.

……

you also can check our website to know for more details, if you need our products catalogue, please contact with us.

Company Information

|

|

|

|

|

Material available |

Surface treatment |

Heat treatment |

|

Low carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be adapted regarding customer requirements. |

Blacking, galvanization, chroming, electrophoresis, color painting, … |

High frequency quenching heat treatment, hardened teeth, carbonizing, nitride, … |

Best China manufacturer & factory CMT series of special, process air compressor With high quality best price

EPG has set up a complete set of quality management system which is provided with advanced inspection and test equipment.

Overview

Quick Details

- Condition:

-

New

- Applicable Industries:

-

OEM

- After Warranty Service:

-

Online support

- Local Service Location:

-

none

- Showroom Location:

-

none

- Type:

-

SCREW

- Configuration:

-

stationary

- Power Source:

-

AC POWER

- Lubrication Style:

-

oil-free

- Brand Name:

-

OEM

- Voltage:

-

–

- Dimension(L*W*H):

-

–

- Weight:

-

–

- Certification:

-

–

- Warranty:

-

1 YEAR

- After-sales Service Provided:

-

Online support

- Working Pressure:

-

OEM

- Machinery Test Report:

-

Provided

- Video outgoing-inspection:

-

Provided

- Marketing Type:

-

Ordinary Product

- Warranty of core components:

-

6 months

- Core Components:

-

OEM

In one way or another, all breathers let air flow between the inside and outside of the gear reducer as the unit warms during startup and cools after shutdown. If the breather is completely shielded from lubricant splash inside the reducer, almost any design will be effective. Unfortunately, this is usually not the case, particularly since most gear reducer hoCat 3 Point Hitch How do I operate the PTO on my tractor? Prior to running the PTO, you will need your tractor to reach the starting RPM (revolutions per minute). Once the starting RPM has been reached you can begin operating the PTO.usings can mount in a variety of positions. If the breather is exposed to oil splash, a bubble of oil typically forms across the breather’s inside orifice, and escaping warm air carries it to the outside. Over time, these small droplets accumulate until the unit is visibly “leaking.”

Online Customization

Product Description

|

Ever-power specialist in making all kinds of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm gearboxes, in-line helical gear speed reducers, parallel shaft helical gear reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, pto drive shafts, special reducer & related gear components and other related products, sprockets, hydraulic system, vaccum pumps, fluid coupling, gear racks, chains, timing pulleys, udl speed variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors, shaft collars low backlash worm gearboxes and so on. furthermore, we can produce customized variators, geared motors, electric motors and other hydraulic products according to customers’ drawings.

|

Packaging & Shipping

Our Services

Also I would like to take this opportunity to give a brief introduction of our Ever-Power company:

Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china.

We have exported many products to our customers all over the world, we have long-time experience and strong technology support.

Some of our customer :

Italy: COMER,GB GEABOX ,SATI, CHIARAVALLI, AMA , Brevini

Germany: SILOKING ,GKN ,KTS

France: Itfran, Sedies

Brazil: AEMCO ,STU

USA: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

……

-Ø Our Company with over twelve year’s history and 1000 workers and 20 sales.

-Ø With over 100 Million USD sales in 2017

-Ø With advance machinery equipments

-Ø With large work capacity and high quality control, ISO certified.

……

you also can check our website to know for more details, if you need our products catalogue, please contact with us.

Company Information

|

|

|

|

|

|

|

|

|

Material available |

Surface treatment |

Heat treatment |

|

Low carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be adapted regarding customer requirements. |

Blacking, galvanization, chroming, electrophoresis, color painting, … |

High frequency quenching heat treatment, hardened teeth, carbonizing, nitride, … |

Compressor manufacturer China in Vereeniging South Africa Claw Air Hose Quick Couplings with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Product Description:

Air hose coupling are recommended to be used in the transfer of air and or water.

The application should be in an open system where the air or water is in motion (dynamic) and not in a closed pressurized (static) condition. This dynamic application involves continuous flow, therefore, back pressure would be relieved by the verynature of the application.

The applicable system should contain pressure relief valves to relieve any excess pressure.

Safety clips and safety cables should be installed on either side of the coupling connection.

1. Casting Air hose coupling ( EPT aircoupling)

EPT air coupling US type, Chicagocoupling (Type B) / European type (Type A)/ Austrilian stand (type S)

Casting method: Investment casting/Sandcasting

2. Sizes: From 1/4″ to 2″ (1/4″, 3/8″, 1/2″, 1″, 1-1/4″, 1-1/2″, 2″)

3. Parts:

Male end

Female end

Hose end W/O collar

Hose end With collar

Two lugs, four lugs

| Material Available | Carbon steel zn plated, Stainless steel, malleable ca EPT iron |

| Size | 1/4″-1″ for two lug, 11/4″-2″ for four lug |

| Sealing | NBR |

| Thread Type | NPT, BSP |

| Working Pressure | 10bar |

| Max Te EPT Pressure | 16bar |

FAQ:

1. What is your term of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

2. How about your delivery time?

A: It usually takes 15 to 30 days, which generally depends on the quantity of your order and our storage.

3. Can I get free samples?

A: Yes, send your address, your tel: +86~13 0571 88828ephone number, po EPT code, and express account number to us, and tel: +86~13 0571 88828l us which samples you need and samples specification.

4. Can you produce products with my own brand?

A: Yes, we can offer EPT services.

Our Company:

HangZhou Doway M&E Co., Ltd. is built in HangZhou China, which is established in 2000. We specialized in manufacturing brass & bronze valves and fittings, water meter accessories and pipe fittings. Our mainly products cover ball valves, angle valves, gate valves, check valves, bib cocks, marine valves, pipe fittings, PPR insert, radiator valves and fittings, camlock and grooved couplings etc.

Nowadays, we are involving in the fields of brass forged, brass investment casting, bronze sand casting, brass/bronze gravity casting etc. Our products are widely used in water and plumbing systems and well recognized in Europe, USA, Middle Ea EPT and EPT Land with competitive price, quality products, and considerate service. Our company passed ISO9001 Certification and CE Approval for our ball valves, and UL approval for our bronze ball valves.

Based on the Spirit “Honesty, Pragmatic, Innovation”, we are proud to own one professional team and provided customers competitive prices, quality products with On Time Delivery. Also we have strong EPT and EPT ability for clients to supply various valves and fittings in brass & bronze material for water solution.

HangZhou Doway M&E Co., Ltd is seeking to be the be EPT cooperator for water plumbing and improve its worth to customers. Please contact us freely to know more detai EPT about what we can bring to your sourcing operation.

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.