JMⅡJ Type Intermediate Shaft Type Diaphragm CouplingJMⅡJ Type Intermediate Shaft Type Diaphragm Coupling...

JMⅡJ Type Intermediate Shaft Type Diaphragm CouplingJMⅡJ Type Intermediate Shaft Type Diaphragm Coupling... JS type housing radial mounting type couplingSelection of JS type housing radial mounting type coupling...

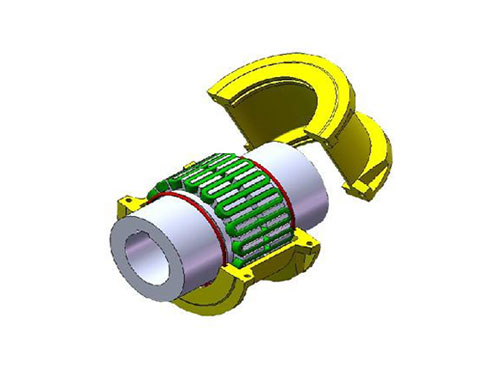

JS type housing radial mounting type couplingSelection of JS type housing radial mounting type coupling... ZLL type elastic pin gear coupling with brake wheelZLL type elastic pin gear coupling with brake wheel...

ZLL type elastic pin gear coupling with brake wheelZLL type elastic pin gear coupling with brake wheel... ML plum-shaped elastic couplingML plum-shaped elastic coupling and other coupling...

ML plum-shaped elastic couplingML plum-shaped elastic coupling and other coupling... HLL type brake wheel elastic pin couplingHLL type brake wheel elastic pin coupling has...

HLL type brake wheel elastic pin couplingHLL type brake wheel elastic pin coupling has...Briefly analyze the alignment method of multi-section clamping diaphragm coupling?

Multi-section clamping diaphragm couplings use parallel or spiral groove system to adapt to various deviations and accurately transmit torque.Multi-section clamping diaphragm couplings usually have good performance and price advantages. In many practical applications of stepping and servo systems, multi-section clamping diaphragm couplings are good products.The one-piece design enables the multi-section clamping diaphragm coupling to realize the advantages of zero-clearance torque transmission and no maintenance.

Correction method

(1) Fix the outer foot on the side of the motor of the lifting accessories coupling, and move the inner foot until the eccentric line between the motor and the pump is zero.In order to prevent the motor from moving freely, after fixing the feet on one side of the motor, the other side should be supported by the top wire.

(2) Fix the inner feet of the coupling and move the outer feet to make the eccentricity of the two wires zero.

(3) After the above two methods are repeated several times, the coupling can be in a good alignment state.

Hoisting parts coupling is an important task in the equipment maintenance process.The principle of aligning is simple, but practical.The alignment methods often used on small pumps include single-meter method, double-meter method, and three-meter method, etc.No matter which method, there is a common feature; the alignment in the horizontal plane is more error-prone than the vertical plane, it is repetitive, time-consuming, and the calculation is cumbersome.

application

Most of the multi-section clamping diaphragm couplings are made of aluminum alloy. Some manufacturers also provide multi-section clamping diaphragm couplings made of stainless steel.The stainless steel multi-section clamping diaphragm coupling also increases the torque bearing capacity and rigidity, and can even reach twice that of similar products made of aluminum alloy.However, this increased torque and rigidity will be largely offset by the increased mass and inertia.Sometimes the bad influence will outweigh its advantages, so users have to look for other forms of couplings.