LMZ-ⅡPlum-shaped elastic coupling with brake wheelLMZ-Ⅱ (formerly MLL-Ⅱ) type with brake wheel plum...

LMZ-ⅡPlum-shaped elastic coupling with brake wheelLMZ-Ⅱ (formerly MLL-Ⅱ) type with brake wheel plum... JMⅡJ Type Intermediate Shaft Type Diaphragm CouplingJMⅡJ Type Intermediate Shaft Type Diaphragm Coupling...

JMⅡJ Type Intermediate Shaft Type Diaphragm CouplingJMⅡJ Type Intermediate Shaft Type Diaphragm Coupling... JB type HG5-251-79 standard frameThe selection of JB type HG5-251-79 standard frame, the original...

JB type HG5-251-79 standard frameThe selection of JB type HG5-251-79 standard frame, the original... JXLD, JBLD model frame (new standard)The JXLD type of this rack series is suitable for...

JXLD, JBLD model frame (new standard)The JXLD type of this rack series is suitable for... JS type housing radial mounting type couplingSelection of JS type housing radial mounting type coupling...

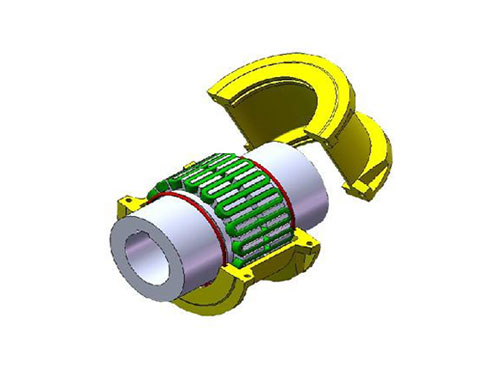

JS type housing radial mounting type couplingSelection of JS type housing radial mounting type coupling...Introduce the installation work and bolt installation process of the plum blossom coupling

The plum blossom coupling is a commonly used coupling. As a mechanical linkage tool, it brings a lot of convenience to the work in use, and the speed of the coupling is also a decisive factor in use.The speed range of the coupling is also determined by different materials, so there are many factors that affect the speed of the coupling.It is characterized by simple structure, no lubrication, high temperature resistance, convenient installation, easy replacement, high performance, and large transmission torque.In addition, the shaft diameter of the main and driven ends should be smaller than the larger radial size of this specification, the tripping speed of the coupling (tripping speed) should be less than the allowable speed of this specification, and the axial size should meet the requirements of the pump layout.When the torque and speed are the same but the main and driven end journals are different, the coupling model should be selected according to the large shaft diameter.For couplings used in different conditions, influencing factors such as the centrifugal force of the outer circle of the coupling and the deformation of elastic elements should be considered, and should be dynamically balanced.Non-metallic elastic element elastic couplings should not be used at high speeds. The deformation of elastic elements is formed at high speeds. Flexible couplings should be selected. High-speed couplings are nothing more than diaphragm couplings and drum gears. Type coupling.

XNUMX. Introduce the installation work and bolt installation process of the plum blossom coupling

(1) Device bolt: Insert the bolt from the outside of the small hole in the flange, pass it through the outside of the large hole of the other flange, put on the buffer sleeve, elastic washer, twist the nut, and tighten the nut with a wrench.If the device is unsuitable or dismantled and replaced, without damaging the shaft and half coupling, it is better to rotate freely after the device is over.

(2) In order to facilitate the installation, it is better to put the two half couplings in the 120-150 incubator or oil tank for preheating in advance, so that the size of the inner hole is enlarged and it is easy to install.After the device, the shaft head cannot protrude from the end surface of the half coupling, and it is better to be flush.Detect the distance between the two halves of the coupling: take the average of the readings of 3-4 points measured along the two inner sides of the flange of the half coupling, and the sum of the measured dimensions of the extension and the two diaphragm groups. The error is controlled within the range of 0-0.4mm.

(3)找正:用百分表检测两半联轴节法兰盘端面和外圆跳动,当法兰盘外圆小于250mm时跳动值应不大于0.05mm;当法兰盘外圆大于250mm时,跳动值应不大于0.08。

(4) Check whether the work is in place first. Before installation, check whether the prime mover and the working machine are out of concentricity, whether there is wrapping paper and bruises on the surface of the two shafts, and the plum blossom coupling is in the two half couplings. Whether there is debris in the hole, whether there is a bruise on the edge of the inner hole, if any, the shaft and half coupling should be cleaned up, and the bruise should be treated with a fine file.Then check whether the inner hole diameter and length of the two half couplings are consistent with the diameter and shaft elongation of the prime mover and working machine.In general selection, it is better to let the length of the prime mover and the working machine end half coupling be less than 10-30mm of shaft elongation.

XNUMX. Analyze the performance of plum coupling under different conditions

(1) Simple structure, convenient assembly and disassembly, and maintenance.

(2) Cushioning: For occasions where the load starts or the working load changes frequently, the coupling needs to have elastic elements that can buffer and reduce vibration to protect the prime mover and the working machine from being damaged or not.

(3) Movability: The mobility of the coupling refers to the ability to compensate the relative displacement of the two rotating components.Factors such as manufacturing and installation errors between the connected components, temperature changes during operation and load deformation, etc., all put forward requirements for portability.Movable performance compensation or additional load between shafts, bearings, couplings and other parts due to relative displacement between rotating components.

(4) It has sufficient strength and service life.

The coupling is composed of two halves, which are respectively connected with the driving shaft and the driven shaft.The general power machine is mostly connected with the working machine by means of a coupling.On the plum coupling, it plays a role of damping, buffering and electrical insulation.The plum blossom coupling elastic body has two colors, red and yellow, and the shape is hard. If the light can't distinguish the quality of the material from the shape.But according to physical changes, the difference in material can be distinguished.The method is to heat water to bring the temperature to 100°C. When the temperature is reached, it can be found that the harder plum coupling elastomer is made of polyurethane, while the soft plum coupling elastomer is made of poly deer.There is another way to identify it by smelling. Good elastomers basically don't have a big smell, while second elastomers have a strong pungent smell.A good plum elastic body becomes light and shiny.And the second plum blossom elastic body is black, not bright.