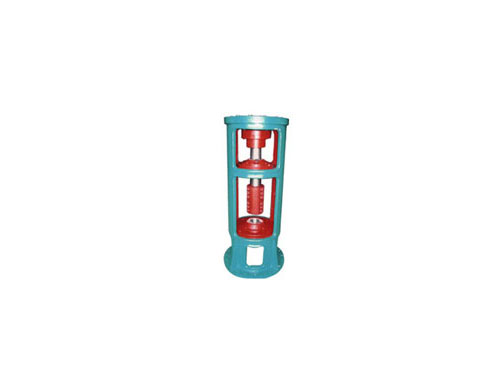

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame...

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame... FCL type elastic sleeve pin couplingThe characteristics of FCL type elastic sleeve pin coupling...

FCL type elastic sleeve pin couplingThe characteristics of FCL type elastic sleeve pin coupling... GLF roller chain couplingGLF roller chain coupling is suitable for hydraulic machinery...

GLF roller chain couplingGLF roller chain coupling is suitable for hydraulic machinery... Roller chain couplingRoller chain couplings can be used in textiles, agriculture...

Roller chain couplingRoller chain couplings can be used in textiles, agriculture... WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth...

WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth...Diaphragm coupling conducts force analysis on diaphragm and the advantages of WGZ drum gear coupling with brake wheel

The force analysis of the diaphragm is carried out. The loads on the diaphragm are: ① the tension and pressure generated by the torque in the diaphragm, ② the bending moment caused by the deflection of the axis, ③ the centrifugal force of the bolt and the diaphragm mass, ④ the diaphragm axis Elastic thrust caused by the displacement, ⑤ bolt pre-tightening force.Torque T makes the tension or compression pressure and mass centrifugal force stress produced by the diaphragm change with the rotation speed.In some installation and operation conditions, ①, ②, ④, and ⑤ are all constant stresses.The bending moment M makes the diaphragm generate elastic thrust, and the stress cyclically changes every time the shaft rotates.

The main failure of the diaphragm coupling is not due to insufficient torsion transmission capacity of the diaphragm assembly, but due to fatigue of the diaphragm and bolt under the action of alternating cyclic compound stress.Therefore, this chapter first calculates the strength of the diaphragm, and the fatigue calculation of the diaphragm is carried out in the next chapter.

The torque that the diaphragm bears is mainly transmitted by the tension and compression force of the diaphragm between the master and slave bolts.In order to simplify the calculation, the following basic assumptions are made:

XNUMX. During operation, the ends of the diaphragm remain parallel;

XNUMX. Only consider the stress caused by the transmitted torque;

XNUMX. Excluding the surface shear force generated by the small relative movement between the diaphragms, that is, all the diaphragms are regarded as a whole;

XNUMX. It is assumed that the force of each active bolt is equal, and the force is along the driving direction.

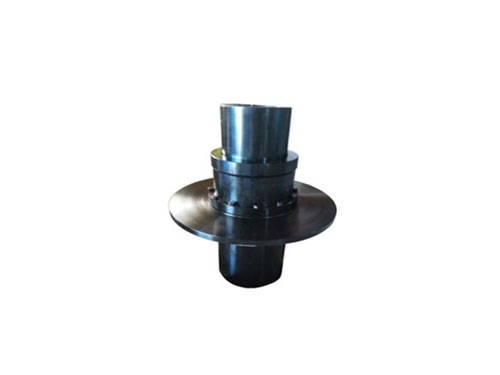

The WGZ drum gear coupling with brake wheel has the ability to compensate for axis deviations such as radial, axial and angular axis. It has compact structure, small gyration radius, large carrying capacity, good transmission speed, low noise and long maintenance period. advantage.When the drum gear coupling is working, therefore, the gear coupling needs to work in a good and sealed state.

The main advantages of WGZ drum gear coupling with brake wheel are:

After carburizing and quenching treatment of drum-shaped tooth meshing tooth surface, the bearing capacity is high; the main failure mode of drum-shaped tooth is wear. After using forced thin oil lubrication, the tooth surface wear is greatly reduced, and the amount of wear is about 10% of grease lubrication. , Circulating thin oil can take away the rolling heat at the end of the roll and the heat generated by the friction of the gear teeth, preventing the reduction of the allowable contact stress on the surface of the gear tooth material; under normal circumstances, there will be no tooth breakage, which meets the requirements of the continuous rolling mill operating characteristics ; The WGZ drum gear coupling with brake wheel can meet the requirements of rolling mill shifting rolling, and it is especially convenient to expand and contract; it is stable in use, clean, and fast.

The external teeth of the WGZ drum gear coupling with brake wheel are divided into two types of tooth shapes: straight teeth and drum teeth. The WGZ drum gear coupling with brake wheel can allow large angular displacements (relative to straight teeth). Gear coupling), which can improve the contact conditions of the teeth, enhance the torque transmission capacity, and prolong the service life.The contact state along the tooth width when there is angular displacement.

Among the wide variety of couplings, WGZ drum gear coupling with brake wheel has the advantages of small size, large transmission torque, good ability to absorb coupling errors, and excellent long-term performance. It is used in medium and heavy machinery. A more common component that connects two drive shafts.In engineering practice, due to manufacturing and installation errors, component deformation, wear, and foundation sinking, the position of the two axes will shift, resulting in axial displacement, radial displacement, angular displacement, and comprehensive displacement.The existence of the offset causes additional dynamic loads on the shafts, bearings, and couplings, causing vibrations and making machine parts work.

With the rapid development of modern industrial technology, more and more technical and economic indicators such as the carrying capacity, performance, speed, circumferential speed, volume and weight of the WGZ drum gear coupling with brake wheels have been put forward increasingly high requirements. WGZ drum gear coupling with brake wheel is developed on the basis of straight gear coupling to meet the technical requirements of large inclination, variable inclination, small size and high performance. The structure of the WGZ drum gear coupling with brake wheel is basically symmetrical.From the direction of the tooth tip, the teeth on the outer gear sleeve are drum-shaped teeth, and the tooth thickness gradually decreases from the center to the two sides. The teeth on the inner gear ring that mesh with it are straight teeth.Because the tooth tip and tooth surface of the external gear sleeve are arc-shaped, the entire coupling is double articulated and flexible, so that it can adapt to the large deflection angle between the two axes. WGZ drum gear coupling with brake wheel plays an important role in production practice.It can compensate the angular error caused by the misalignment of the two connecting shafts, the axial and radial installation errors, and allow the two shafts to have a specific displacement.

Discuss the background of the WGZ drum gear coupling with brake wheels. The coupling is an important mechanical basic component. Its function is to connect the driving shaft and the driven shaft, and transmit torque to make the two shafts rotate together.Under special working conditions, such as the WGZ drum gear coupling with brake wheel for glass industrial mixers, because the force state of the drum gear is a multi-tooth contact, non-linear problem, the traditional calculation model and the actual project have a lot of problems. The failure problems such as the deviation of the tooth surface, the fatigue damage of the tooth surface and the deformation of the connecting bolt hole are still problems that need to be discussed and solved urgently.