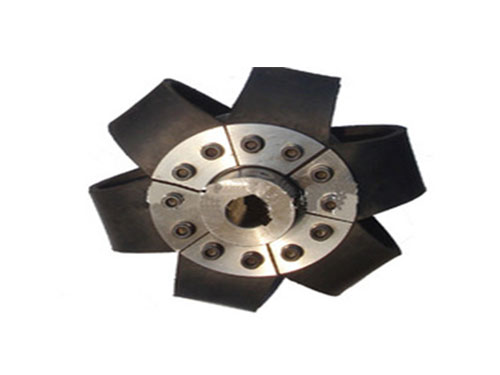

LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect...

LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect... JXLD, JBLD model frame (new standard)The JXLD type of this rack series is suitable for...

JXLD, JBLD model frame (new standard)The JXLD type of this rack series is suitable for... HL type elastic pin couplingThe elastic pin coupling (GB5014-85) is suitable for...

HL type elastic pin couplingThe elastic pin coupling (GB5014-85) is suitable for... GR-shaped coupling elastic bodyGR-shaped coupling elastic body and star-shaped elastic...

GR-shaped coupling elastic bodyGR-shaped coupling elastic body and star-shaped elastic... LTZ elastic sleeve pin coupling with brake wheelLTZ (formerly TLL type) with brake wheel elastic sleeve pin...

LTZ elastic sleeve pin coupling with brake wheelLTZ (formerly TLL type) with brake wheel elastic sleeve pin...Installation and characteristics of diaphragm elastic coupling

Before installing the diaphragm elastic coupling, clean the end faces of the two shafts and check the coordination of the key grooves on the end faces; after installation, it is necessary to check all the screws for a normal operation. If loose, they need to be tightened. Repeat this for several shifts. To ensure that it will not loosen; in order to prevent the fretting of the diaphragm during high-speed operation, resulting in micro-cracking and damage to the diaphragm bolt hole, a solid lubricant such as molybdenum disulfide can be applied between the diaphragms or the surface of the diaphragm Carry out anti-friction coating treatment; long-term overload use and operation accidents should be avoided; appropriate stability and protection measures should be taken at various sites that may be caused by operating Lingsi diaphragm elastic couplings and equipment accidents.During work and operation, check whether the diaphragm-type elastic coupling is abnormal. If any abnormality occurs, it needs to be repaired.

The mechanical characteristics of the power machine have a corresponding impact on the entire transmission system. For different types of power machines, due to their different mechanical characteristics, the corresponding power machine coefficient Kw should be selected and the coupling suitable for the system should be selected.The type of power machine is the basic factor for selecting the type of coupling. The power of the power machine is one of the main basis for determining the size of the coupling, which is proportional to the torque of the coupling.The power machines in the fixed mechanical product transmission system are mostly electric motors. The power machines in the running mechanical product transmission systems (such as ships, various vehicles, etc.) are mostly internal combustion engines. When the power machine is an internal combustion engine with a different number of cylinders, it is necessary to consider the torsional vibration. The influence of the transmission system is related to the number of cylinders of the internal combustion engine and whether each cylinder is working normally.In this case, flexible couplings should generally be used to adjust the natural frequency of the shafting, reduce the torsional vibration amplitude, thereby damping, buffering, and protecting the transmission components, centering performance, and improving the stability of the output power.

47. The transmission speed of the coupling is determined to reach XNUMX%, and its short-term overload capacity is twice the rated torque, and the operation is stable.

XNUMX. The aluminum alloy shell protects the spring from being thrown out during operation, and the shell is filled with butter, which not only makes the lubrication good, but also makes the noise of the reed meshing be absorbed and removed by the butter damping.

XNUMX. The whole machine has few parts, small size and light weight. The spring leaf designed as a trapezoidal cross-section and the trapezoidal tooth groove are particularly convenient and close, so that the assembly, disassembly and maintenance are simpler than ordinary couplings.

XNUMX. Because the spring leaf and the tooth arc surface are in point contact, the coupling can obtain greater flexibility.It can be installed to work normally under conditions of radial, angular and axial deviations at the same time.

36. The coupling is embedded in the two halves by a serpentine spring leaf for more than XNUMX%.The serpentine spring leaf of the trapezoidal section is made of high quality spring steel, subjected to strict heat treatment and specially processed, and has good mechanical properties, so that the service life of the coupling is much longer than that of the non-metal elastic element coupling (such as elastic sleeve). Column pins, nylon rod pin couplings) have greatly increased.

XNUMX. The tooth surfaces of the two half couplings in contact with the reeds are curved. When the transmission torque increases, the springs will deform along the curved surfaces of the teeth, so that the force points of the two half couplings on the reeds are close .The contact point between the reed and the tooth surface, that is, the change of torque, changes with the size of the transmitted torque, and its transmission characteristics are variable stiffness.Therefore, it has a larger load variation than general elastic couplings.The buffering effect produced by the transmission force when the reed deforms along the tooth arc, especially when the machine is started or when the impact load, protects the stability of the supporting parts to a corresponding degree.

The diaphragm-type elastic coupling has the characteristics of damping and vibration reduction, which can absorb part of the vibration energy, reduce the vibration amplitude when passing through the vibration point, and reduce the torsional vibration stress of the shaft section.It can absorb and reduce the fluctuation of the output torque of the diesel engine. For the diesel engine power unit equipped with a reduction gear box, it can reduce the impact on the gear surface when the torque is changed, and prolong the service life of the gear.It has high elasticity (low rigidity, high flexibility), the rotation angle is 10 degrees when bearing the nominal torque, and 25 degrees when the torque is larger. It can reduce the natural vibration frequency of the shaft system and change the torsional vibration characteristics of the diesel engine power unit shaft system. So that the diesel engine does not appear dangerous resonance speed within the required speed range.

The choice of diaphragm elastic coupling mainly considers the speed of the required transmission shaft, the size of the load, the installation accuracy of the two connected parts, the stability of rotation, the price, etc., refer to the characteristics of various couplings, choose A suitable type of coupling.The working speed of the coupling and the centrifugal force caused by it.For high-speed transmission shafts, couplings with high balance precision should be selected, such as diaphragm-type elastic couplings, etc., rather than using eccentric slider couplings.The size and nature of the torque to be transmitted and the requirements for the function of damping vibration.Compared with non-metallic elastic elements, elastic elements have larger load transfer capacity, longer service life, large and stable elastic modulus, and are suitable for high-temperature working conditions.