NL type drum gear couplingThe shaft hole types are cylindrical (Y), conical...

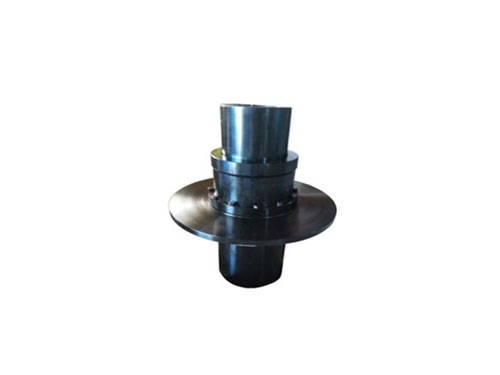

NL type drum gear couplingThe shaft hole types are cylindrical (Y), conical... WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth...

WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth... Universal couplingThe universal coupling uses the characteristics of its mechanism...

Universal couplingThe universal coupling uses the characteristics of its mechanism... Tire coupling for LLA metallurgical equipmentThe tire coupling for LLA metallurgical equipment is...

Tire coupling for LLA metallurgical equipmentThe tire coupling for LLA metallurgical equipment is... GL type roller chain couplingGL-type roller chain coupling AUTOCAD renderings...

GL type roller chain couplingGL-type roller chain coupling AUTOCAD renderings...The classification of couplings and the characteristics of drum gear couplings

Coupling materials can be roughly divided into sections (round steel), castings (cast iron or cast steel), forgings, etc., and cast steel and forgings are most of the choices of coupling materials.Profiles are generally in the form of coupling materials that are often used for smaller couplings. For example, plum blossom couplings below ML5 (outer diameter is 125). However, when such small couplings are manufactured using profiles, Note that quenching and tempering is the key to improving material performance. The choice of coupling material is directly related to the performance of the coupling.

Cast steel materials are suitable for larger and more complex coupling structures (mainly due to the low utilization rate of forging materials), for example, drum gear couplings above GICL15 (outer diameter is 580) , And this kind of coupling is often suitable for transmission systems that have large torque transmission ratios and are subjected to reciprocating impact loads. Therefore, even if cast steel is used due to the price of the coupling, the cast steel must be strictly controlled The material composition of the material and casting defects (pores, sand holes, shrinkage porosity, etc.), and the casting steel material is required to have the corresponding tempering treatment (casting internal stress).Forging materials have the advantages of increased material density and no casting defects. However, forging materials may have the shortcomings of forging cracks (such as the transition part of the shoulder of the SL Oldham coupling), so the forging materials should be normalized (Forging internal stress) At the same time, it detects the defects of forging cracks.

一、膜片联轴器:(1)膜片型弹性联轴器;(2)高扭矩刚性和高好用度;(3)零回转间隙;(4)顺时针和逆时针回转特性相同;(5)不锈钢膜片补偿角向和轴向偏差;(6)夹紧螺丝固定。

二、一体成型弹性联轴器:(1)一体成型的金属弹性联轴器;(2)零回转间隙、可同步运转;(3)弹性作用补偿径向、角向和轴向偏差;(4)高扭矩刚性和的好用度;(5)顺时针和逆时针回转特性全部相同;(6)铝合金及不锈钢材料;(7)固定方式主要有顶丝和夹紧两种。

三、波纹管联轴器:(1)高扭矩刚性和好用度;(2)零回转间隙;(3)顺时针和逆进针回转特性全部相同;(4)波纹管结构补偿角向、径向和轴向偏差;(5)可适合用于精度和稳定性要求较不错的系统;(6)定位夹紧螺丝固定。

四、十字滑块联轴器:(1)联轴器中间用十字滑块联接;(2)容许大的径向和角向偏差;(3)零回转间隙;(4)高扭矩刚性和好用度;(5)结构简单、抗油腐蚀和电气绝缘;(6)夹紧螺丝固定。

五、梅花联轴器:(1)中间弹性体链接;(2)可吸收振动、补偿径向、角向和轴向偏差;(3)抗油与电气绝缘;(4)顺时针与逆时针回转特性全部相同;(5)有两种不同硬度弹性体;(6)定位螺丝固定。

In the process of daily use, the coupling often has the following four failures:

XNUMX. The axial displacement of the gear ring of the coupling is large, even unable to mesh.

XNUMX. The coupling has broken teeth.

XNUMX. The bolt on the coupling is broken.

XNUMX. The tooth surface of the coupling is severely damaged.

The causes of these failures mainly include the following two aspects:

XNUMX. Insufficient or lack of oil in the coupling of lifting accessories.Or improper use of grease may result in calcification of the grease, resulting in the inability to lubricate between the tooth surfaces, or poor lubrication, resulting in serious tooth surface wear.

Treatment method: As long as the new grease is replaced, qualified grease oil is injected on schedule to prevent oil leakage, and the amount of oil can be avoided.

XNUMX. The horizontality and coaxiality error of the two shafts is too large, which exceeds the range that the coupling can compensate, which makes the meshing of the shaft teeth and the internal teeth inaccurate, resulting in local contact and additional torque.

Handling method: This kind of fault handling is more difficult and needs to be stopped for handling.That is to realign, or realign the side of the reducer, or realign the side of the reel.First find out the part with large offset error, so first measure the coupling to which side it is offset, that is, measure the levelness and coaxiality of the main shaft and the level and coaxiality of the reducer main shaft, and then re-according to the quality scale Copy level and align it, and then it will malfunction.

In addition, the horizontality and concentricity of the two shafts have a large error, which causes the coupling to be awkward when rolling.The reason for the gear wear of the above-mentioned lifting fitting coupling is basically similar. In addition to the normal force, the connecting bolt is also subjected to additional bending moment, which causes it to break.This is the main reason.This kind of reason usually occurs when the level difference between the left and right sides of the reducer main shaft is large.Furthermore, bolts with small diameters, insufficient strength, or poor bolt materials can also cause bolts to break.

Features of drum gear coupling:

XNUMX. The transmission speed is not bad.Based on the characteristics of the warp, drum-shaped teeth have generally been used instead of straight-tooth couplings.The specifications of drum-shaped gear couplings meet the corresponding standards.The drum-shaped gear coupling has high rigidity, flexibility, and no elasticity, so it is not suitable for machinery that requires damping, buffering, and two-shaft alignment;

XNUMX. The drum-shaped tooth surface changes the contact conditions of the inner and outer teeth, avoids the disadvantages of squeeze the edge of the straight tooth tooth under the condition of angular displacement, and stress concentration. At the same time, it changes the friction and wear of the tooth surface and reduces the noise. , Long maintenance period;

15. Carrying.Under the same outer diameter of the inner gear sleeve and the large outer diameter of the coupling, the carrying capacity of the drum gear coupling is on average 20-XNUMX% higher than that of the straight gear coupling;

Fourth, the angular displacement compensation is large.When the radial displacement is equal to zero, the allowable angular displacement of the spur gear coupling is 1º; while the allowable angular displacement of the drum gear coupling is 1º; 30”, an increase of 50%, in the same mold Under the condition of number, number of teeth and tooth width, the allowable angular displacement of the drum-shaped gear is larger than that of the straight tooth;

XNUMX. The tooth end of the outer gear sleeve is in the shape of a horn, which makes the assembly and disassembly of the inner and outer gears easy.

Next:Nothing