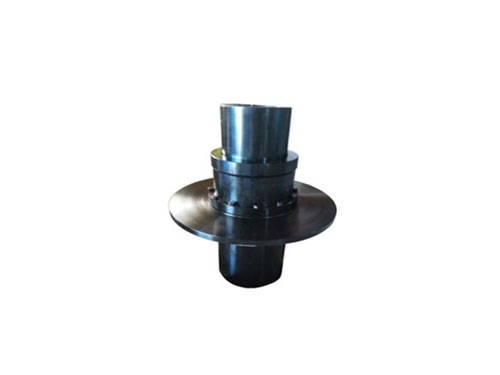

WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth...

WGP type drum gear coupling with brake discThe gear coupling is made of the same number of teeth... WGT type gear coupling with intermediate sleeveWGT type connecting middle sleeve gear coupling is working...

WGT type gear coupling with intermediate sleeveWGT type connecting middle sleeve gear coupling is working... Three-jaw coupling for pumpThe three-jaw coupling for pumps uses a number of non...

Three-jaw coupling for pumpThe three-jaw coupling for pumps uses a number of non... HL type elastic pin couplingThe elastic pin coupling (GB5014-85) is suitable for...

HL type elastic pin couplingThe elastic pin coupling (GB5014-85) is suitable for... NGCL type drum gear coupling with brake wheelNGCL type drum gear coupling with brake wheel...

NGCL type drum gear coupling with brake wheelNGCL type drum gear coupling with brake wheel...Explanation of Spiral Grooving of Drum Gear Coupling

What are the materials of the gears in the drum gear coupling?

[1] Cast steel: Cast steel has poor mechanical properties and small applications. It is usually used to make large gears, large gear rings, etc. that cannot be forged!

【2】铸铁:常用的牌号为:HT20-40、HT30-54或QT60-2。铸铁的强度和冲击韧性较低,常用于大齿圈或轻载、无冲击、齿数多的齿轮列如、列如:滚齿机的范成、进给和差动交换齿轮中的一些大齿轮!

[3] Plastic: The commonly used material is nylon or bakelite, which is mainly used for light-duty gear couplings to reduce noise.

【4】锻钢:质中碳或低碳钢,中碳或低碳合金是制造齿轮联轴器的常用的材料,中碳或低下碳合金常用的牌号为:45、45Cr、40MNb、40MnVB、38CrMoA1A等。其中38CrMoA1A是氮化钢,氮化处理后表面硬度可相当于HRC-65-70。其他各种牌号通常进行高频加热表面蘸火,起硬度为:HRC48-53,40Cr也可氮化处理,表面硬度相当于HRC54-57,受大冲击载荷的齿轮可用低碳钢和低碳合金制造,常用牌号:20、20Cr、20CrMoTi、20Mn2B等。

General mechanical parts, the shaft of the machine is linked by it, so that the shaft can rotate naturally.If it is a running machine, the coupling also needs to have the function of buffering, reducing pressure and improving the dynamic performance of the shafting.The coupling is connected by the driving shaft and the driven shaft. Generally, the power machine is mostly connected with the working machine by means of a coupling, and it is a commonly used coupling part for the shaft transmission of mechanical products.

The coupling has a corresponding torque range. When the coupling is overloaded, it will automatically disconnect to protect the machine.Therefore, when choosing the coupling, the appropriate rated torque should be selected accordingly. Too small is not good, and too large is not good.The elastic coupling also has the function of buffering, damping vibration and improving the dynamic performance of the shafting.The main function of the coupling is as follows: it connects the motor shaft with the mechanical shaft, and transmits the torque of the motor to the mechanical shaft for force transmission.

What is the spiral groove of the drum gear coupling?

[1] Drum-shaped gear couplings use parallel or spiral grooving systems to adapt to various deviations and transmit torque. They usually have good performance and price advantages. In many practical applications of stepping and servo systems, The one-piece design enables the drum gear coupling to achieve the advantages of zero torque transmission and no maintenance.

[2] The drum gear coupling has a continuous multi-turn long slot. This coupling has excellent elasticity and a small bearing load. It can withstand various deviations and is more suitable for correcting deviations. Angular and axial deviations, but the ability to deal with eccentricity is relatively poor, because the spiral groove must be bent in two different directions at the same time, which will generate a large internal pressure, which will lead to premature damage to the coupling.

[3] The long spiral groove coupling can easily bend under various deviations, but it will also have the same effect on the rigidity of the coupling under the torsional load, and the excessive rotation under the torsional load will Affect the accuracy of the coupling and weaken its overall performance.

After the drum gear coupling is assembled, the spline pair should slide freely and the joint should rotate flexibly.After assembling, clean the surface, except for the flange end face and end face key with anti-rust grease, brush the anti-rust primer once and spray paint.When packing, it should be leveled and clamped tightly.Another thing that can’t be ignored is that during lathe processing, the skill content of the worker who processes the coupling and the skills he injects, the degree and gloss of the processed coupling are the key factors that affect the service life of the coupling. .

Introduction to the factors of wear of drum gear coupling

[1] Moisture plus the impurities left by wear will remain in the coupling for a long time, which will accelerate the wear of the coupling, and the direct coupling will fail.It is understood that the high-pressure cylinder shaft seal of the steam turbine unit has continuously leaked steam. During operation, the crew has to drain the bottom of the oil tank every day to clarify that the smooth oil contains water.

[2] Since the two rotating parts connected by the gear coupling move axially during rotation, the coupling contact tooth surface has good smoothness. When the contact tooth surface is worn and the large particle size of sludge impurities is greater than 25μm , It will lose the smoothing effect. At the same time, the more heat generated by the axial movement, the higher the contact tooth surface temperature, the easier it is to wear.

[3] When the turbine shaft seal is adjusted improperly, steam will enter the bearing box, and the smooth effect of water-carrying oil will be greatly reduced, and it will also speed up the corrosion process of iron parts.

[4] The internal smoothness of the drum-shaped gear coupling is poor, and it cannot take away the heat and sludge impurities generated by running-in. Long-term operation will cause the wear of the coupling.The inside of the gear coupling should be smooth, and the smooth oil has the function of smoothing and washing.

[5] When the unit is installed, there is no fuel injection pipe in practice. As long as a small amount of smooth oil splashed in the front bearing box enters the coupling, long-term operation will cause the lack of smoothness of the outer gear sleeve and inner gear ring of the coupling and wear.

Next:Nothing