SL cross slider couplingCross slider coupling is also known as metal slider...

SL cross slider couplingCross slider coupling is also known as metal slider... GLF roller chain couplingGLF roller chain coupling is suitable for hydraulic machinery...

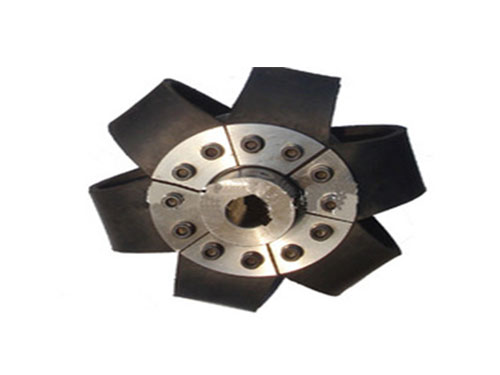

GLF roller chain couplingGLF roller chain coupling is suitable for hydraulic machinery... LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect...

LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect... YLD type flange couplingYL type flange coupling can be made of gray cast iron or carbon...

YLD type flange couplingYL type flange coupling can be made of gray cast iron or carbon... ZL type elastic pin gear couplingZL type elastic pin gear coupling is the use of...

ZL type elastic pin gear couplingZL type elastic pin gear coupling is the use of...Coupling type selection and structural characteristics of diaphragm elastic coupling

Coupling is a mechanical component that is mainly used to connect two rotating shafts in mechanical transmission, so as to transmit torque or rotation angle; it can also be used for equipment protection of stabilizer; shaft and shaft cannot be separated during movement, only It can be separated when the equipment stops running.In addition, if an abnormality occurs during operation and the transmission torque is too large, the coupling will be damaged at first to avoid damage to the motor or other transmission components.

When selecting the coupling type, the following items should be considered.

XNUMX. The allowable dimensions and installation methods are for the convenience of assembly, adjustment and maintenance of the operating space.For large couplings, it should be possible to disassemble and assemble without the need for axial movement of the shaft.

XNUMX. The size and nature of the torque to be transmitted, the requirements for buffering and damping functions, and whether resonance may occur.

XNUMX. The relative displacement of the axis of the two shafts caused by manufacturing and assembly errors, shaft load and thermal expansion deformation, and relative movement between components.

In addition, the working environment, service life, lubrication, sealing and economy should also be considered, and then refer to the characteristics of various couplings to select a suitable coupling type.

In the high-speed and heavy-duty power transmission, some couplings also have the function of buffering, damping and improving the dynamic performance of the shafting.The coupling is composed of two halves, which are respectively connected with the driving shaft and the driven shaft.The general power machine is mostly connected with the working machine by means of a coupling, which is a commonly used coupling part for the shaft transmission of mechanical products. In the late 20th century, coupling products developed rapidly. In product design, how to choose a coupling that can meet the requirements of the machine from a variety of couplings with different performances? For most designers, it is always A troubled question.

During the process of hot-fitting the diaphragm couplings, if their temperature rises to XNUMX degrees Celsius, some personnel on the site should pay attention to stability. In addition, for such a product, when the actual assembly is carried out, it will also It is necessary to record the temperature well, and to make a series of records of the entire temperature through a variety of different methods. Under this recording mode, there will be a variety of different current values, and the same, their span Each liter should not exceed XNUMX degrees Celsius, and such a leap mode is relatively recognized by more people.In the actual working process of the diaphragm coupling, when they are working, especially during the entire rotation, there is no gap at all. This is a particularly important point, and this is also what they are in the process of processing. To be sure, all diaphragm couplings will undergo related inspections before they leave the factory.Diaphragm couplings will have particularly excellent elasticity, which means that to some extent, in the process of absorption or installation, diaphragm components will be produced in the form of three-dimensional deformation to withstand the misalignment of the driving and driven flanges.

What should you pay attention to during hot assembly? During the actual installation of diaphragm couplings, there are some precautions of their own, especially if hot assembly is to be carried out, then they must have some of their own attention.If you plan to heat the diaphragm coupling, you should choose a diaphragm coupling that matches them long before you go. In fact, they must make sure that they are all doubled in the process of hot-fitting. Yes, and only in this way can it meet the installation mode of the entire machine. Therefore, such a choice is particularly important. It is necessary to find out the relevant number or mark, and then make the relevant mark on it.The elastic element of the diaphragm coupling is composed of a thin stainless steel diaphragm laminated into a diaphragm assembly. The diaphragm usually has a waist shape, a polygonal ring shape, etc., and the bolts on the same distribution circle are connected to the driving and driven flanges. .

The diaphragm-type elastic coupling uses a thin spring plate, which is connected with the two halves of the coupling by bolts or other coupling methods to realize the coupling of the elastic coupling of the two shafts.

The structural characteristics of the diaphragm elastic coupling are as follows:

20. The working temperature is -250~+XNUMX℃, and no lubrication is required, and it can work in corrosive media.

XNUMX. Compared with gear couplings, it has simple structure, easy processing and maintenance, low vibration, no noise, and is suitable for use at high speeds.

XNUMX. Convenient for assembly, disassembly and inspection. The driving and driven part of the transmission system can be disengaged without axial displacement during disassembly.

XNUMX. It is widely used in metallurgy, steel rolling, mining, chemical industry, shipbuilding, pumps, fans and other industries.

XNUMX. According to the transmission torque and flexibility, the connecting rods are divided into four, six and eight equal parts.

25. Large carrying capacity, large scope of application, long service life, and nominal torque of 1000000~XNUMXN.m.