LTZ elastic sleeve pin coupling with brake wheelLTZ (formerly TLL type) with brake wheel elastic sleeve pin...

LTZ elastic sleeve pin coupling with brake wheelLTZ (formerly TLL type) with brake wheel elastic sleeve pin... YLD type flange couplingYL type flange coupling can be made of gray cast iron or carbon...

YLD type flange couplingYL type flange coupling can be made of gray cast iron or carbon... ML plum-shaped elastic couplingML plum-shaped elastic coupling and other coupling...

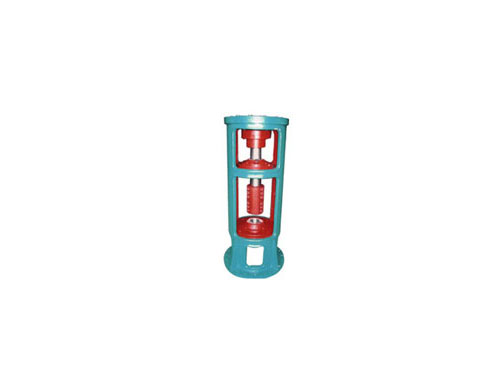

ML plum-shaped elastic couplingML plum-shaped elastic coupling and other coupling... XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame...

XS type double fulcrum rackThere are two shafts arranged in the XS type double pivot frame... Clamping spline plum blossom elastic couplingClamping spline plum blossom elastic coupling...

Clamping spline plum blossom elastic couplingClamping spline plum blossom elastic coupling...Diaphragm coupling has great ability to compensate for misalignment, easy to install

Choosing a suitable coupling is a key step to make good use of the coupling. At the design stage, you have to consider what type of coupling to choose. Compared with the gear coupling, the coupling diaphragm has no relative sliding. It needs lubrication, sealing, no noise, basically no maintenance, easy to manufacture, and can partially replace gear couplings.The coupling diaphragm is composed of several groups of diaphragms (stainless steel thin plates) that are alternately connected to the two halves of the coupling with bolts. Each group of diaphragms is composed of several stacked ones. The diaphragms are divided into connecting rods and different shapes. Sliced.The characteristic of the diaphragm is a bit like a bellows coupling. In fact, the way the coupling transmits torque is similar.The diaphragm itself is very thin, so it is easy to bend when the relative displacement load is generated, so it can withstand up to 1.5 degrees of deviation, while generating a lower bearing load in the servo system.Diaphragm couplings are often used in servo systems. Diaphragms have good torque rigidity, but are slightly inferior to bellows couplings.On the other hand, the diaphragm coupling is very delicate and can be easily damaged if it is misused in use or not installed correctly.Therefore, it is necessary to determine that the deviation is within the tolerance range of the normal operation of the coupling.

Diaphragm coupling has great ability to compensate for misalignment, easy to install

1. All-metal structure, large torsion transmission capacity, long service life: The diaphragm coupling adopts a metal diaphragm as an elastic element, which has a large load transmission capacity, and there are no non-metal parts in the entire product, no aging problems, and long service life Long, and suitable for harsh environment.

2. Great ability to compensate for misalignment and easy installation and alignment: The diaphragm coupling adopts austenitic stainless steel diaphragm, which can withstand large deformations while transmitting torsion, thereby compensating for the misalignment of the two shafts.The non-metal elastic coupling is restricted by the low strength and easy aging of the non-metal elastic element, which not only has a short life, but also has a small compensation ability.Gear couplings are restricted by the relative slip speed of the tooth surface and lubrication conditions. According to the information, the relative slip speed of the tooth surface should not be greater than 0.12m/s. The angular compensation ability is small.Therefore, non-metal elastic couplings and gear couplings require higher installation and alignment.Once the misalignment exceeds the allowable range, it will cause quick failure of the coupling.

3. The axial and angular stiffness is low, and the impact on the equipment is small: the diaphragm coupling uses a thin metal diaphragm as the elastic element, and the angular and axial stiffness is low, so the additional axial force and additional bending moment are small .Because the tooth surface of the gear coupling can slide relatively, people often think that the gear coupling can compensate for large angular and axial misalignment without additional impact on the unit.In fact, this idea is wrong.After the elastic diaphragm coupling is loaded, due to friction and misalignment of the two shafts, a large additional axial force and additional bending moment will be generated on the shaft and the bearing.

4. Dry coupling, without lubrication: Diaphragm couplings rely on metal diaphragms to transmit torque and absorb deformation caused by misalignment. There is no relative movement between parts, no friction and wear, so no lubrication is required. The development direction of oil-free process equipment.The gear coupling is a rigid movable coupling. It relies on the relative slip between the tooth surfaces to compensate for the misalignment of the two shafts. Therefore, the gear coupling needs to be lubricated, and the lubrication condition determines the gear coupling The key to good or bad work.Especially when it is running at high speed, it is more prominent, such as the separation and leakage of oil under the action of centrifugal force, as well as the choice of lubricating oil, often because the lubrication design uses the bearing lubricating oil of the connected machine instead of the load capacity. Appropriate gear lubricant.Therefore, the lubrication problem of high-speed gear couplings is particularly prominent.On the other hand, the wear caused by the relative slippage of the tooth surface will cause a series of problems such as sludge and imbalance.Therefore, although gear couplings were once an important choice for high-speed and high-power applications, with the emergence and development of diaphragm couplings, gear couplings have gradually faded out.

The diaphragm coupling is composed of at least one diaphragm and two shaft sleeves.The diaphragm is fastened to the shaft sleeve with a pin and will not loosen or cause backlash between the diaphragm and the shaft sleeve.Some consumers provide two diaphragms, and some provide three diaphragms, with one or two rigid elements in the middle, and the two sides are connected to the shaft sleeve.The characteristic of the diaphragm coupling is a bit like a bellows coupling. In practice, the way the coupling transmits torque is similar.

Diaphragm couplings are commonly used in shaft transmission of various mechanical devices, such as water pumps (especially high-power, chemical pumps), fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining High-speed power transmission systems of machinery, metallurgical machinery, aviation (helicopters), and naval vessels are commonly used in high-speed transmission shafts after being dynamically balanced.