Star flexible coupling

Elastic sleeve pin coupling

Diaphragm coupling series

Elastic pin coupling

Drum type gear coupling series

Plum-shaped elastic coupling

Rigid coupling series

Tyre coupling series

Slider coupling series

Universal coupling series

Roller chain coupling

Water pump coupling

Various coupling accessories

Industrial expansion sleeve

Serpentine spring coupling accessories

Reducer bracket series

LMZ-ⅡPlum-shaped elastic coupling with brake wheelLMZ-Ⅱ (formerly MLL-Ⅱ) type with brake wheel plum...

LMZ-ⅡPlum-shaped elastic coupling with brake wheelLMZ-Ⅱ (formerly MLL-Ⅱ) type with brake wheel plum... HL type elastic pin couplingThe elastic pin coupling (GB5014-85) is suitable for...

HL type elastic pin couplingThe elastic pin coupling (GB5014-85) is suitable for... JXLD, JBLD model frame (new standard)The JXLD type of this rack series is suitable for...

JXLD, JBLD model frame (new standard)The JXLD type of this rack series is suitable for...SWP-B type has telescopic short universal coupling

SWP-B type has the option of telescopic short universal coupling:

The choice of coupling mainly considers the speed of the required transmission shaft, the size of the load, the installation accuracy of the two connected parts, the stability of rotation, the price, etc., refer to the characteristics of various couplings, and choose a suitable one. Coupling type.The following points can be considered when making specific choices:

1. Due to reasons such as manufacturing, installation, load deformation and temperature changes, it is difficult to maintain strict alignment of the two shafts after installation and adjustment.There is a degree of displacement in the x and Y directions and the deflection angle CI.When the radial displacement is large, you can choose a slider coupling, and when the angular displacement is large or the connection of two intersecting shafts, you can choose a universal coupling.When the two shafts produce a large additional relative displacement during the working process, a flexible coupling should be used.

2. The working speed of the coupling and the centrifugal force caused by it.For high-speed transmission shafts, couplings with high balance accuracy, such as diaphragm couplings, should be selected, rather than slider couplings with eccentricity.

3. The size and nature of the torque to be transmitted and the requirements for the function of damping vibration.

For example, gear couplings can be used for high-power and heavy-duty transmissions.For severe impact loads or transmissions requiring shaft torsional vibration, tire couplings can be used.Most couplings have been standardized or standardized.The designer's task is to choose, not design.

The basic steps for selecting a coupling are as follows: select the type of coupling according to the size of the transmitted load, the speed of the shaft, the installation accuracy of the two parts to be connected, etc., refer to the characteristics of various couplings, and choose a suitable coupling器型。 Type.

The following points can be considered when making specific choices:

1. The size and nature of the torque to be transmitted and the requirements for the function of buffering and damping.For example, for high-power and heavy-duty transmissions, gear couplings can be selected; for transmissions that require severe impact loads or shaft torsional vibration, tire couplings and other couplings with high elasticity can be selected.

2. The working speed of the coupling and the centrifugal force caused by it.For high-speed transmission shafts, couplings with high balance accuracy, such as diaphragm couplings, should be selected, rather than slider couplings with eccentricity.

3. The magnitude and direction of the relative displacement of the two axes.When it is difficult to keep the two shafts in strict alignment after installation and adjustment, or when the two shafts will have a large additional relative displacement during the working process, a flexible coupling should be used.For example, when the radial displacement is large, you can choose a slider coupling, and when the angular displacement is large or the connection of two intersecting shafts, you can choose a universal coupling.

4. The sex and working environment of the coupling.Generally speaking, couplings made of metal elements that do not require lubrication are better; couplings that require lubrication are easily affected by the perfect degree of lubrication and may pollute the environment.Couplings containing non-metallic components such as rubber are more sensitive to temperature, corrosive media and strong light, and are prone to aging.

5. Manufacturing, installation, maintenance and cost of the coupling.Under the premise of meeting the convenience of use, couplings that are convenient for assembly and disassembly, simple for maintenance, and low cost should be selected.For example, the rigid coupling is not only simple in structure, but also easy to assemble and disassemble, and can be used for low-speed, high-rigidity drive shafts.General non-metallic elastic element couplings (such as elastic sleeve pin couplings, elastic pin couplings, plum-shaped elastic couplings, etc.), due to their good comprehensive capabilities, are widely used in general small and medium-sized Power transmission.

LAK saddle block elastic coupling

LAK saddle block elastic coupling...

LAK saddle block elastic coupling

LAK saddle block elastic coupling...

Roller chain coupling

Roller chain coupling can be used for spinning...

Roller chain coupling

Roller chain coupling can be used for spinning...

Serpentine spring coupling

The serpentine spring coupling uses...

Serpentine spring coupling

The serpentine spring coupling uses...

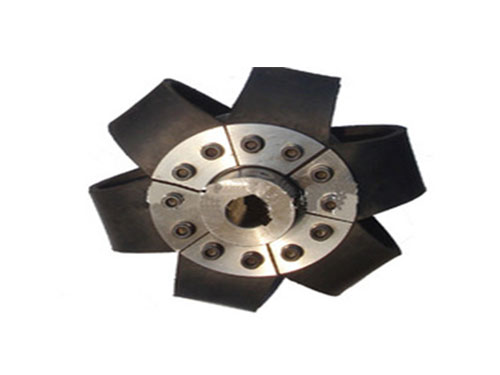

Three-jaw coupling for pump

The three-jaw coupling for pumps uses...

Three-jaw coupling for pump

The three-jaw coupling for pumps uses...