Guangdong star elastic coupling

Guangdong elastic sleeve pin coupling

Guangdong diaphragm coupling series

Guangdong elastic pin coupling

Guangdong drum gear coupling series

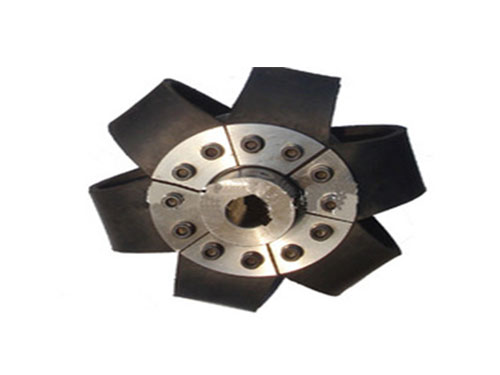

Guangdong plum-shaped elastic coupling

Guangdong rigid coupling series

Guangdong tire coupling series

Guangdong Slider Coupling Series

Guangdong Universal Coupling Series

Guangdong roller chain coupling

Guangdong water pump coupling

Guangdong various coupling accessories

Guangdong Industrial Expansion Set

Guangdong serpentine spring coupling accessories

Guangdong reducer bracket series

Guangdong DJM type diaphragm couplingDiaphragm coupling forging materials need to be inspected...

Guangdong DJM type diaphragm couplingDiaphragm coupling forging materials need to be inspected... Guangdong LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect...

Guangdong LAK saddle block elastic couplingLAK saddle block elastic coupling is used to connect... Guangdong JM Ⅱ type non-counterbore basic diaphragm couplingJMⅡ type non-counterbore basic diaphragm coupling...

Guangdong JM Ⅱ type non-counterbore basic diaphragm couplingJMⅡ type non-counterbore basic diaphragm coupling...Guangdong DJM type diaphragm coupling

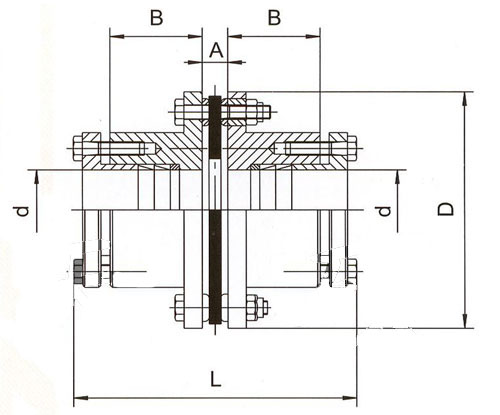

The main dimensions and basic parameters of DJM expansion sleeve coupling single-type diaphragm coupling

specification | Aperture d mm | D mm | L mm | A mm | B mm | Weight kg | Permissible speed rpm | Nominal torque Nm | Allowable compensation | |

Angular (°) | Axial mm | |||||||||

01 | 8-22 | 68 | 90 | 6.1 | 26 | 0.85 | 20000 | 33 | 1 | ± 0.8 |

02 | 10-32 | 81 | 95 | 6.6 | 26 | 1.2 | 20000 | 90 | 1 | ± 1.0 |

03 | 10-35 | 93 | 110 | 8.4 | 29 | 1.7 | 18000 | 173 | 1 | ± 1.2 |

04 | 10-42 | 104 | 124 | 11.2 | 34 | 2.7 | 15000 | 245 | 1 | ± 1.4 |

05 | 15-50 | 126 | 152 | 11.7 | 42 | 6.5 | 13000 | 420 | 1 | ± 1.6 |

06 | 15-60 | 143 | 170 | 11.7 | 48 | 8.9 | 12000 | 772 | 1 | ± 1.8 |

07 | 20-70 | 168 | 210 | 16.8 | 58 | 15.8 | 10000 | 1270 | 1 | ± 2.5 |

Diaphragm coupling forging materials must have an inspection certificate. If substitute materials are required, the purchaser's consent must be obtained and written documents must be obtained.Forgings should be forged on a hydraulic or forging hammer with sufficient tonnage. Forging should have a sufficient forging ratio to forge the entire section through to obtain a uniform structure.The axis of the forging should be equivalent to a steel ingot.Forgings shall be formed by forging steel ingots or billets.Double-length forging is allowed, and it should generally be subjected to separate heat treatment.Heat treatment and machining requirements: post-forging heat treatment: forgings should be pre-heated after forging for organization and machinability.Rough machining: Rough machining should be carried out before heat treatment of forging properties, leaving a small machining allowance.Performance heat treatment: Forgings should be quenched and tempered to achieve the required performance.Machining after performance heat treatment: After the mechanical properties are qualified, the forging is processed to the size and surface roughness specified by the drawing provided by the buyer.But if the cutting amount on any surface exceeds 5mm, the forging shall undergo stress relief treatment.Stress-relief treatment: The temperature for forgings to be stress-relief should be 30° lower than the final tempering temperature. After heat preservation, it should be cooled slowly.If the stress relief temperature is not lower than the final tempering temperature of 30°, the forgings shall be subjected to the mechanical performance test again after stress relief.

江苏DJM type diaphragm coupling Guangdong DJM type diaphragm coupling

Guangdong WF type non-telescopic flange universal coupling

Universal coupling is a kind of joint...

Guangdong WF type non-telescopic flange universal coupling

Universal coupling is a kind of joint...

Guangdong pump with elastic sleeve pin coupling

Elastic sleeve pin coupling for pump...

Guangdong pump with elastic sleeve pin coupling

Elastic sleeve pin coupling for pump...

Guangdong NGCL type drum gear coupling with brake wheel

NGCL type drum gear type with brake wheel...

Guangdong NGCL type drum gear coupling with brake wheel

NGCL type drum gear type with brake wheel...

Guangdong KC type sprocket coupling

KC series sprocket coupling is used...

Guangdong KC type sprocket coupling

KC series sprocket coupling is used...